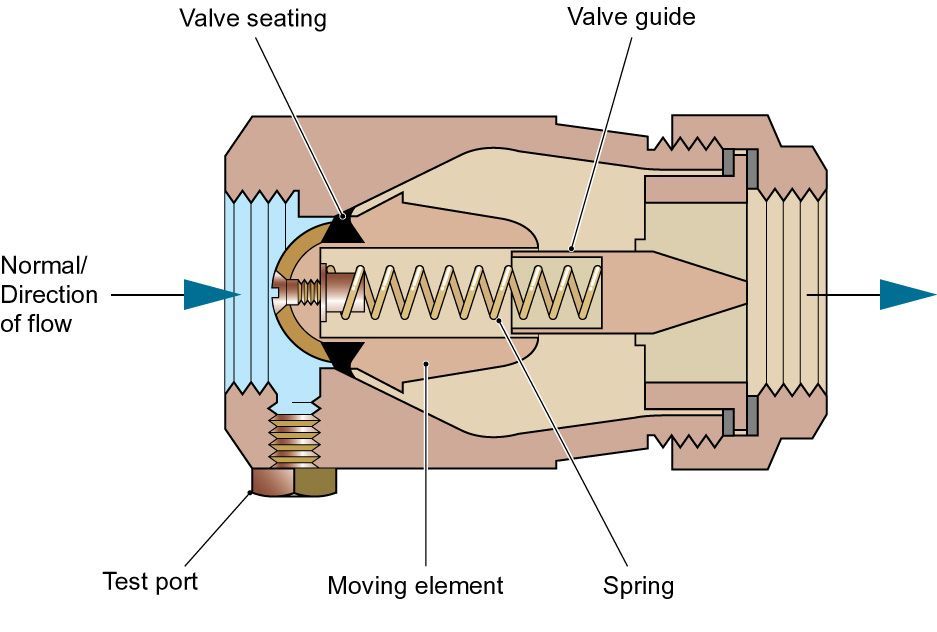

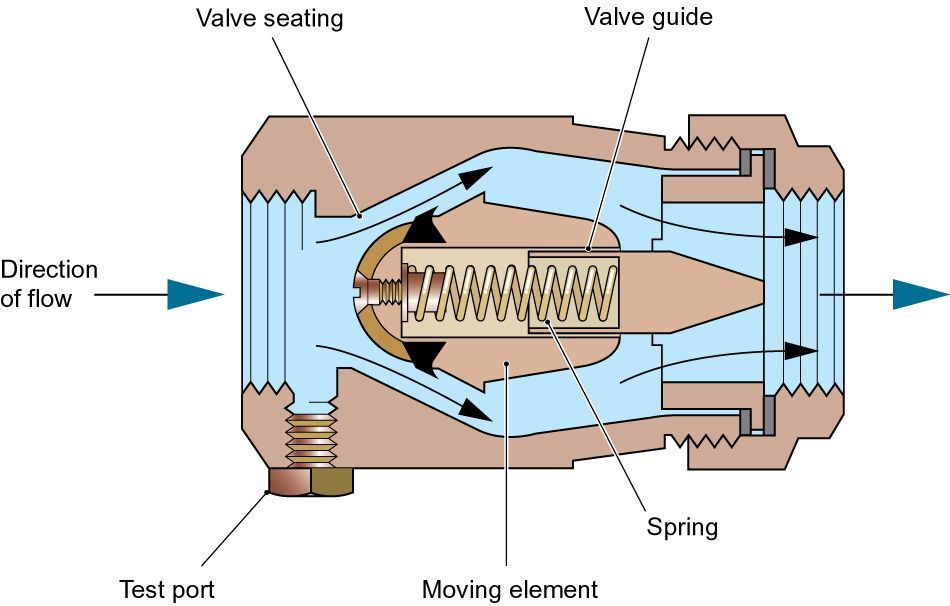

A double check valve is a mechanical backflow protection device. Comprising of two single check valves in series, a double check valve permits water to flow from upstream to downstream but not in the reverse direction.

A double check valve is rated by the Regulators as suitable backflow protection against both back siphonage and back pressure for contamination risks no greater than fluid category 3.

Double check valves should be inspected and maintained every 12 months: non-verifiable double check valves should be replaced every 10 years (BS EN 806: 5).

There are two ways to verify the backflow protection capabilities of a double check valve, both rely on satisfying a specification including performance testing. These are:

Conformity with BS EN 13959, the British Standard for both single and double checks valves, this also includes provision for fittings incorporating these devices (or equivalent).

or

Conformity with all of the tests from the Regulators Specification for fittings applicable to devices intended to be used as a single or double check valve.

We use cookies to give you the best possible experience with Water Regs UK. Some are essential to provide website functions and ensure the website is secure. We also use cookies to help us understand how people use the site and to make improvements. Click "Accept All" to enable recommended settings or click "Manage cookies" to adjust your settings. For more details, see our Cookie Policy.