If a premises has any form of mains water supply, including a back-up supply, then the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland, apply.

These legal requirements play an important role in protecting public health and safeguarding water supplies. Their purpose includes preventing the contamination and waste of water supplied by a water undertaker once it has entered a customer’s plumbing system.

There are a number of key design requirements for troughs and animal drinking bowls including:

The trough/drinking bowl must be watertight

An inlet arrangement supplying water to the trough/drinking bowl must:

Be of an appropriate quality and standard to control the flow

Be rigidly and securely fixed

Be protected against environmental, accidental and animal damage

The supply to the trough/drinking bowl must be protected by a suitable form of fluid category 5 backflow protection.

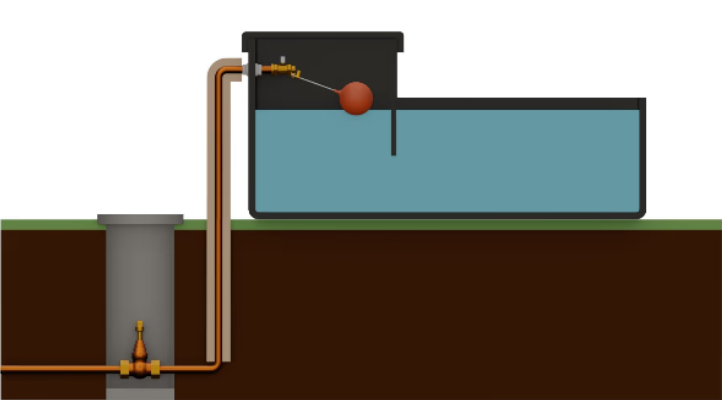

The easiest way to prevent backflow from happening is to ensure a suitable gap is maintained between the water inlet feeding the trough or drinking bowl and the overflow or spill over level. Alternatively, where multiple troughs or drinking bowls are supplied from the same distribution pipe, a break tank arrangement fed via a Type AA, AB or AD arrangement could be used to provide backflow protection.

To minimise waste when maintaining or replacing components a servicing valve should be installed as close as practical to the inlet arrangement.

Stop valves which isolate trough(s)/drinking bowl(s) will also help to minimise waste in the event of a leak and enable pipework and troughs/drinking bowls not in use over the winter to be isolated and drained, which will help to prevent frost damage. Don’t forget to label which troughs/drinking bowls a stop valve controls.

All water fittings must be protected against environmental, accidental, and animal damage. For example, pipework laid at a depth less than 750 mm must be protected. This includes any above ground and outside the thermal envelop, which must be ducted, insulated and sealed. Sealing will help to prevent damage by rodents which is a common cause of leaks. In the case of troughs fitting a raised service box, which does not compromise any air gap providing backflow protection, will protect the inlet arrangement.

To stop the inlet from becoming submerged and prevent waste of water as a result of continuous spillage, troughs and drinking bowls should be installed level.

Regulation 3 England & Wales

Regulation 3 Northern Ireland

Byelaw 3 Scotland

Regulation 4 England & Wales

Regulation 4 Northern Ireland

Byelaw 4 Scotland

Regulation 5 England & Wales

Regulation 5 Northern Ireland

Byelaw 5 Scotland

Schedule 2 paragraph 2

Schedule 2 paragraph 3

Schedule 2 paragraph 4

Schedule 2 paragraph 5

Schedule 2 paragraph 6

Schedule 2 paragraph 7

Schedule 2 paragraph 8

Schedule 2 paragraph 10

Schedule 2 paragraph 11

Schedule 2 paragraph 15

Schedule 2 paragraph 30

Regulation 5 England & Wales

Regulation 5 Northern Ireland

Byelaw 5 Scotland

Schedule 2 paragraph 2

Schedule 2 paragraph 3

Schedule 2 paragraph 4

Schedule 2 paragraph 7

Schedule 2 paragraph 8

Schedule 2 paragraph 11

Schedule 2 paragraph 15

Agricultural booklet

Regulators' Specification for backflow

Regulation 4(1)(a) compliance guidance

Regulation 4(1)(a) guidance: BS 6920 compliance overview

Full list

We use cookies to give you the best possible experience with Water Regs UK. Some are essential to provide website functions and ensure the website is secure. We also use cookies to help us understand how people use the site and to make improvements. Click "Accept All" to enable recommended settings or click "Manage cookies" to adjust your settings. For more details, see our Cookie Policy.