If a premises has any form of mains water supply, then the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland, apply.

If a premises has any form of mains water supply, then the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland, apply.

These legal requirements play an important role in protecting public health and safeguarding water supplies. Their purpose includes preventing the contamination and waste of water supplied by a water undertaker once it has entered a customer’s plumbing system.

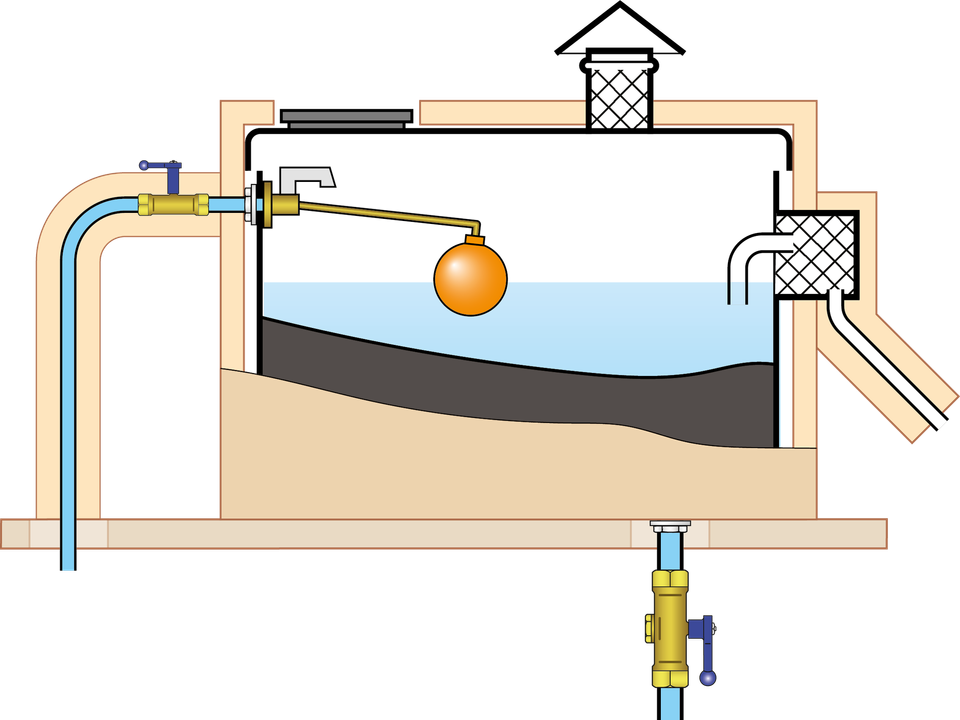

A cold water storage cistern may be installed for various reasons including:

To provide backflow protection

To provide a reserve supply in the event of any disruption to the incoming cold water supply

To reduce the maximum demand on the cold water supply

To reduce the supply pressure

In many cases the local water undertaker will need to be given advanced notice of the proposed installation of any cold water cistern. This is an important simple and essential check to minimise the risk to water supplies.

Please be aware as well as providing storage a cold water storage cistern may be providing backflow protection for installations downstream. For this reason, they should not be removed without firstly consulting with the local water undertaker.

Even if a cold water storage cistern is to be used solely for storing water for drinking, washing, bathing or other purposes requiring it to be wholesome, as a condition of consent it is likely the local water supplier will require backflow protection to be installed. This is typically achieved by suitable air gap arrangement; in some circumstances a double check valve may also be required.

Regulation 4 England & Wales

Regulation 4 Northern Ireland

Byelaw 4 Scotland

Regulation 5 England & Wales

Regulation 5 Northern Ireland

Byelaw 5 Scotland

Schedule 2 paragraph 2

Schedule 2 paragraph 3

Schedule 2 paragraph 4

Schedule 2 paragraph 5

Schedule 2 paragraph 6

Schedule 2 paragraph 7

Schedule 2 paragraph 8

Schedule 2 paragraph 9

Schedule 2 paragraph 10

Schedule 2 paragraph 11

Schedule 2 paragraph 14

Schedule 2 paragraph 15

Schedule 2 paragraph 16

Schedule 2 paragraph 20

Schedule 2 paragraph 27

Regulation 5 England & Wales

Regulation 5 Northern Ireland

Byelaw 5 Scotland

Schedule 2 paragraph 2

Schedule 2 paragraph 3

Schedule 2 paragraph 4

Schedule 2 paragraph 7

Schedule 2 paragraph 8

Schedule 2 paragraph 9

Schedule 2 paragraph 11

Schedule 2 paragraph 14

Schedule 2 paragraph 15

Schedule 2 paragraph 16

Schedule 2 paragraph 20

Schedule 2 paragraph 27

Cisterns storing drinking water

Installing cold water storage

Keeping a cold water storage cistern safe

Linking cold water storage cisterns

Pipe identification information note

Plumbing maintenance: at home

Plumbing maintenance: commercial premises

Underground storage

Regulators' Specification for backflow

Full list of Publications

We use cookies to give you the best possible experience with Water Regs UK. Some are essential to provide website functions and ensure the website is secure. We also use cookies to help us understand how people use the site and to make improvements. Click "Accept All" to enable recommended settings or click "Manage cookies" to adjust your settings. For more details, see our Cookie Policy.