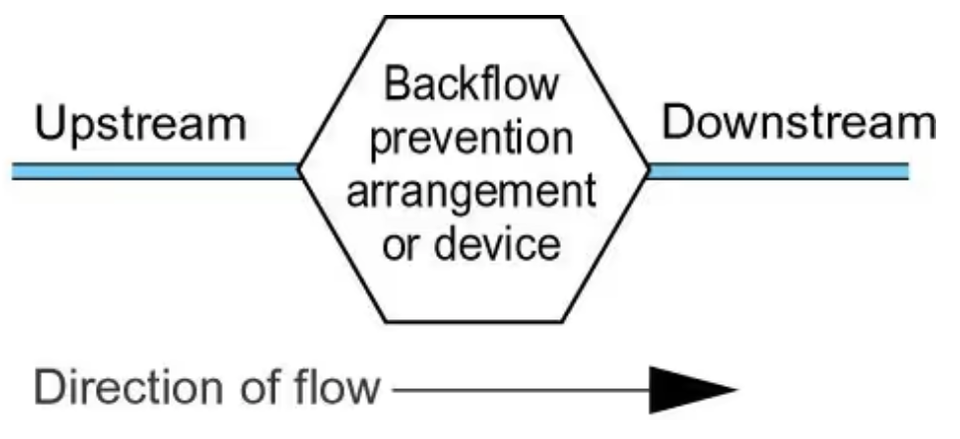

For the purposes of the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland, backflow occurs when fluid flows in the opposite to the intended or normal direction of flow.

There are two types of backflow, back pressure and back siphonage.

The circumstances which could lead to backflow are a common occurrence across the UK, contamination of public water supplies by backflow of fluids from customers premises is not theoretical. It is an ever present threat to water quality and public health.

Good design and the installation of suitable backflow prevention arrangements are key to avoiding backflow, which is why notification is so important.

Schedule 2 paragraph 15 of the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland require every plumbing system to incorporate protection against backflow. This is often referred to as point of use backflow protection. It can be provided by an air or tap gap arrangement or a mechanical backflow prevention device.

Backflow prevention arrangements and devices permitted under the regulations/byelaws need to be approved by the regulator or alternatively authorised as a relaxation. Relaxations allow a water undertaker the discretion to accept an arrangement as preventing backflow.

Wherever practicable plumbing systems should be protected against backflow without the necessity to rely on mechanical backflow protection devices.

Regulations & Byelaws which apply include but are not limited to:

Schedule 1

Schedule 2 paragraph 24

Schedule 2 paragraph 30

Legal Requirements & Guidance:

We use cookies to give you the best possible experience with Water Regs UK. Some are essential to provide website functions and ensure the website is secure. We also use cookies to help us understand how people use the site and to make improvements. Click "Accept All" to enable recommended settings or click "Manage cookies" to adjust your settings. For more details, see our Cookie Policy.