The water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland are legal requirements which apply to all premises which have, or will have, a mains water supply, even it is only a backup supply.

An important item of public health legislation, their purpose is to protect drinking water supplies. Their objective is to prevent contamination, misuse, waste, undue consumption or erroneous measurement of water. They do this by setting legal requirements for the design, installation, operation and maintenance of water fittings, including water-using appliances.

Any premises with, or which will have, a mains water supply falls under the scope of the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland.

These regulations/byelaws place a legal duty on the owners or occupiers of premises and anyone undertaking plumbing work for them to ensure all the applicable requirements are complied with. Failure to do so is a criminal offence.

The water fittings regulations/byelaws apply to all premises with a mains water supply, even if it is only a backup supply arrangement.

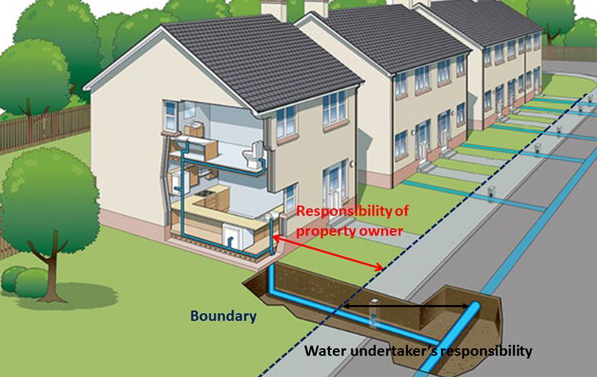

The regulations/byelaws apply to all water fittings (both above and below ground) and water using appliances from the point where the mains water enters the property (usually the stop tap at the property boundary) to the point it is used by the consumer.

The current regulations/byelaws do not apply to plumbing systems which were lawfully installed

under previous water fittings byelaws. However, water undertakers can require changes to be made to such systems under other legislation.

We all take it for granted when we turn the tap on there will be water and it will be safe to drink.

We all take it for granted when we turn the tap on there will be water and it will be safe to drink.

The water fittings regulations/byelaws exist to help ensure this is the case. Their purpose is to prevent customers plumbing systems contaminating and wasting drinking water supplies, an important public health measure to protect both those within the premises and the wider community.

The need for everyone to have access to clean, safe drinking water is why it is so important for those responsible for water fittings to ensure plumbing systems are compliant with all, not just some of the applicable parts of the regulations/byelaws.

Additional information

Those responsible for water fittings should ensure plumbing systems are compliant with all, not just some of the applicable parts of the regulations/byelaws.

Water fittings themselves have to be compliant

Where, and the way in which water fittings are installed has to be compliant

How plumbing systems are used and maintained has to be compliant

Risk | Examples of measures which could be taken |

Water fittings, including water using appliances, contaminate or waste drinking water supplies | Ensure water fittings are of an appropriate quality and standard as well as suitable for installation |

Proposed changes to plumbing systems contaminate or waste drinking water supplies | Notification this is a simple and essential check which will highlight potential contamination or waste concerns Consider using an approved contractor |

Existing plumbing system installations: changes to, or the way they are operated contaminates or wastes drinking water supplies | Be aware of the legal obligations imposed by the water fittings regulations/byelaws, including the need to notify Ensure plumbing is installed and maintained in accordance with the manufacturer’s installation instructions and any relevant regulatory requirements. Use the installation guidance published by the local water undertaker and Water Regs UK Consider using an approved contractor In the case of specific installation queries contact the local water undertaker for advice |

The current regulations/byelaws do not apply to plumbing systems which were lawfully installed under previous water fittings byelaws. However, water undertakers can require changes to be made to such systems under other items of legislation.

Additional information

Water undertakers have a legal duty to enforce the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland, in their area of supply.

To check the requirements are being complied with water undertakers will carry out inspections and take enforcement action when contraventions/offences are identified.

For further details please refer to water undertakers’ enforcement policies.

A water company which has the statutory duty to supply water and/or sewerage services to premises within a specific geographical area.

Additional information

If a premises has any form of mains water supply, then in many cases the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland, make it a legal requirement (regulation 5) for the local water undertaker to be given advanced notice of any proposed plumbing work. This is an important simple and essential check to minimise the risk to water supplies.

The water undertaker has 10 working days to respond to a valid notification. The proposed work should not start until after the 10 days is up.

The water undertaker can either decline or grant consent. If consent is granted conditionally then these conditions must be met.

If no response is received consent is deemed to have been granted. The proposed plumbing work can proceed but the owner/occupier has the legal obligation to ensure it is fully compliant with the water fittings regulations/byelaws.

If a premises has any form of mains water supply, then in many cases the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland, make it a legal requirement (regulation 5) for the local water undertaker to be given advanced notice of any proposed plumbing work. This is an important simple and essential check to minimise the risk to water supplies.

The water undertaker has 10 working days to respond to a valid notification. The proposed work should not start until after the 10 days is up.

The water undertaker can either decline or grant consent. If consent is granted conditionally then these conditions must be met.

If no response is received consent is deemed to have been granted. The proposed plumbing work can proceed but the owner/occupier has the legal obligation to ensure it is fully compliant with the water fittings regulations/byelaws.

The conditions of consent will be found in the consent letter issued by the local water undertaker. This will have been sent to the address listed in the advanced notification.

If there are any questions relating to the approval granted, please contact the local water undertaker for further information

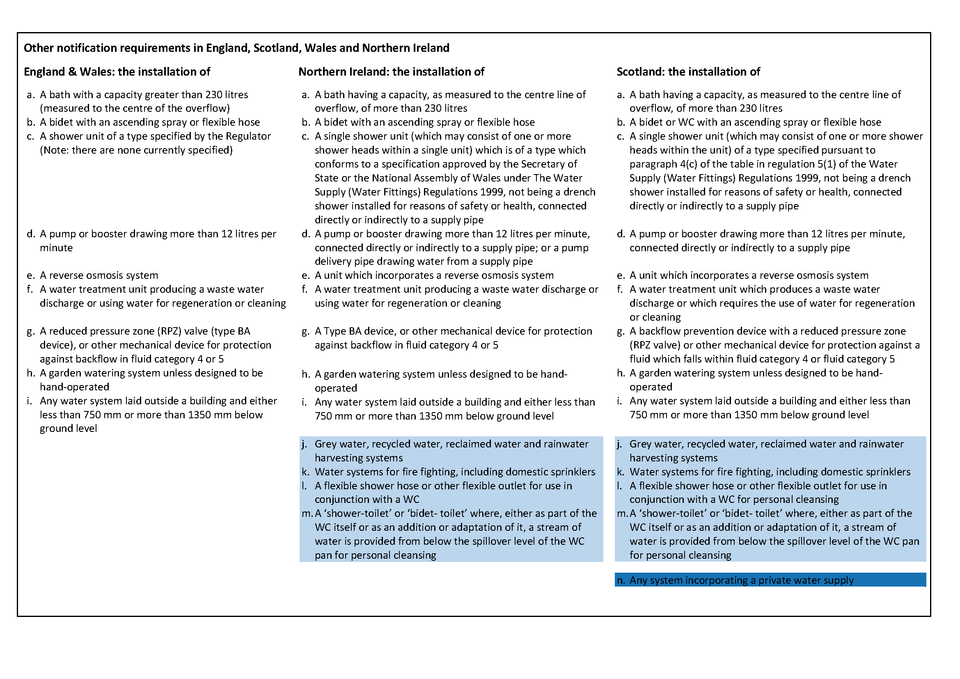

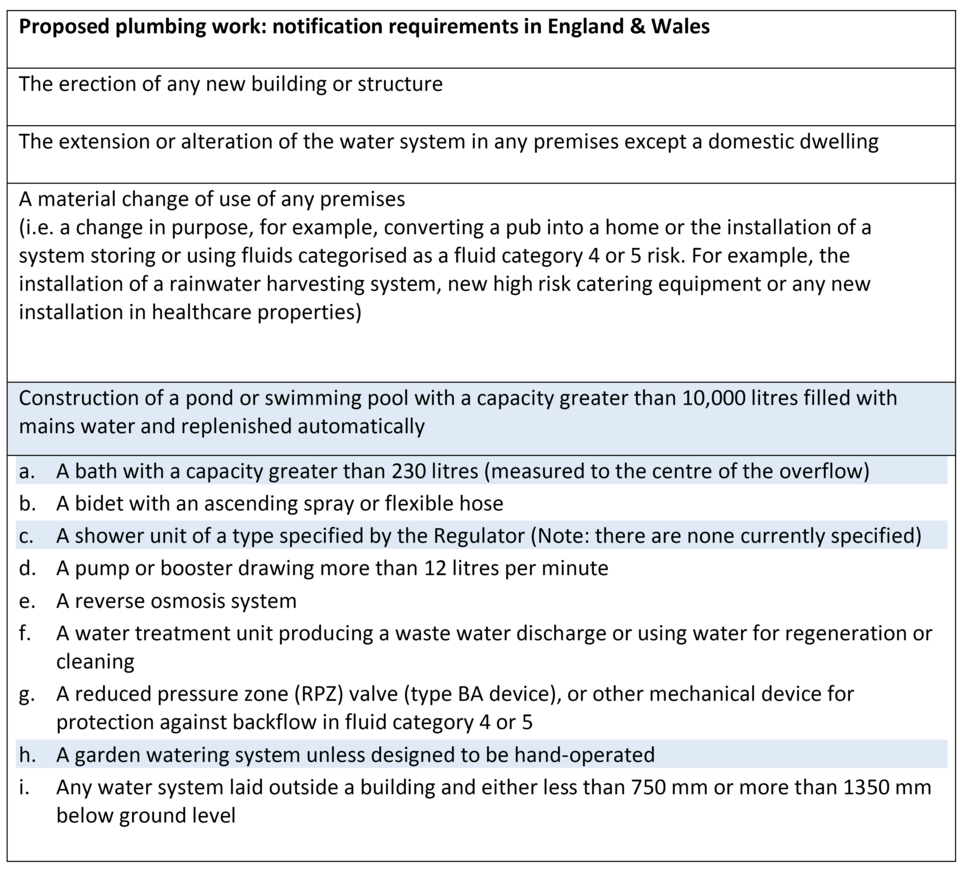

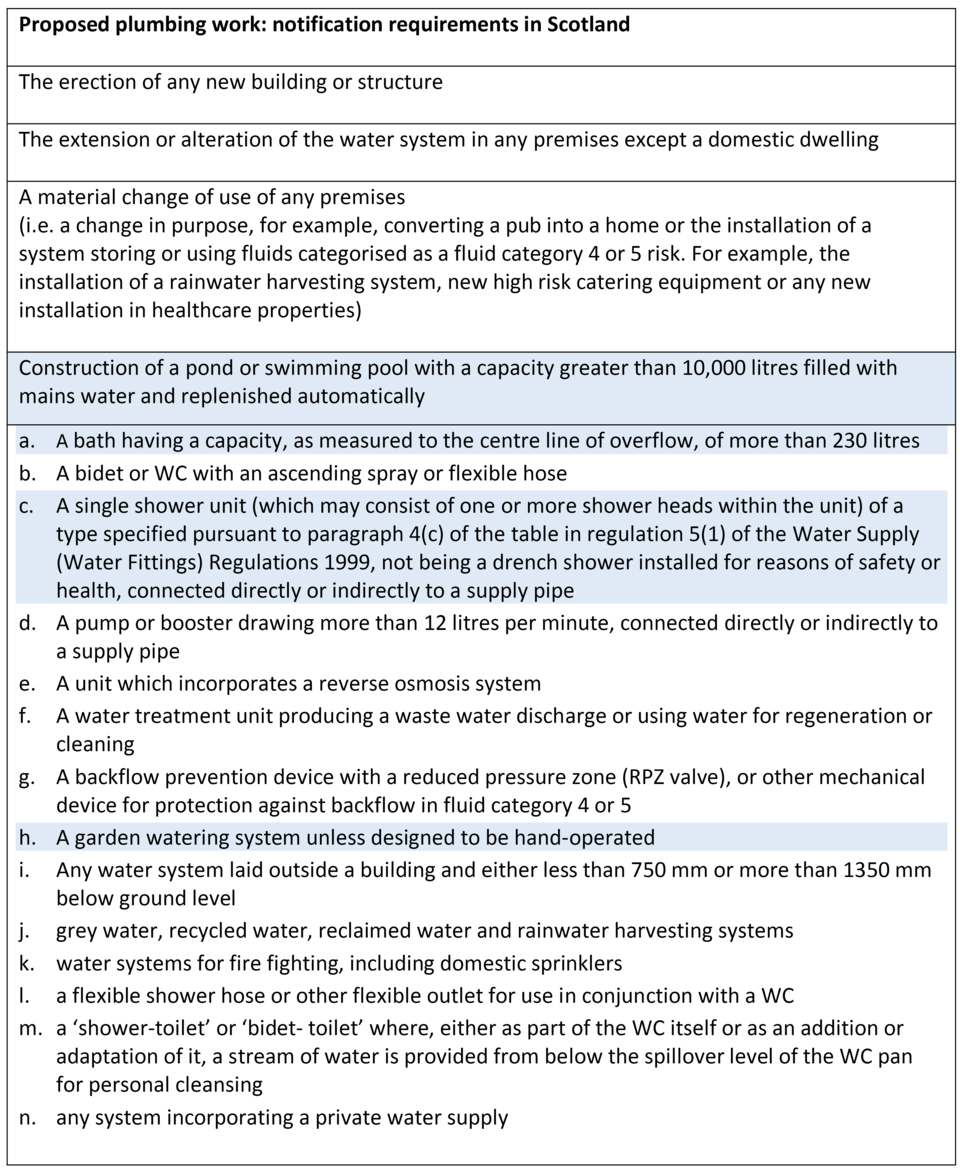

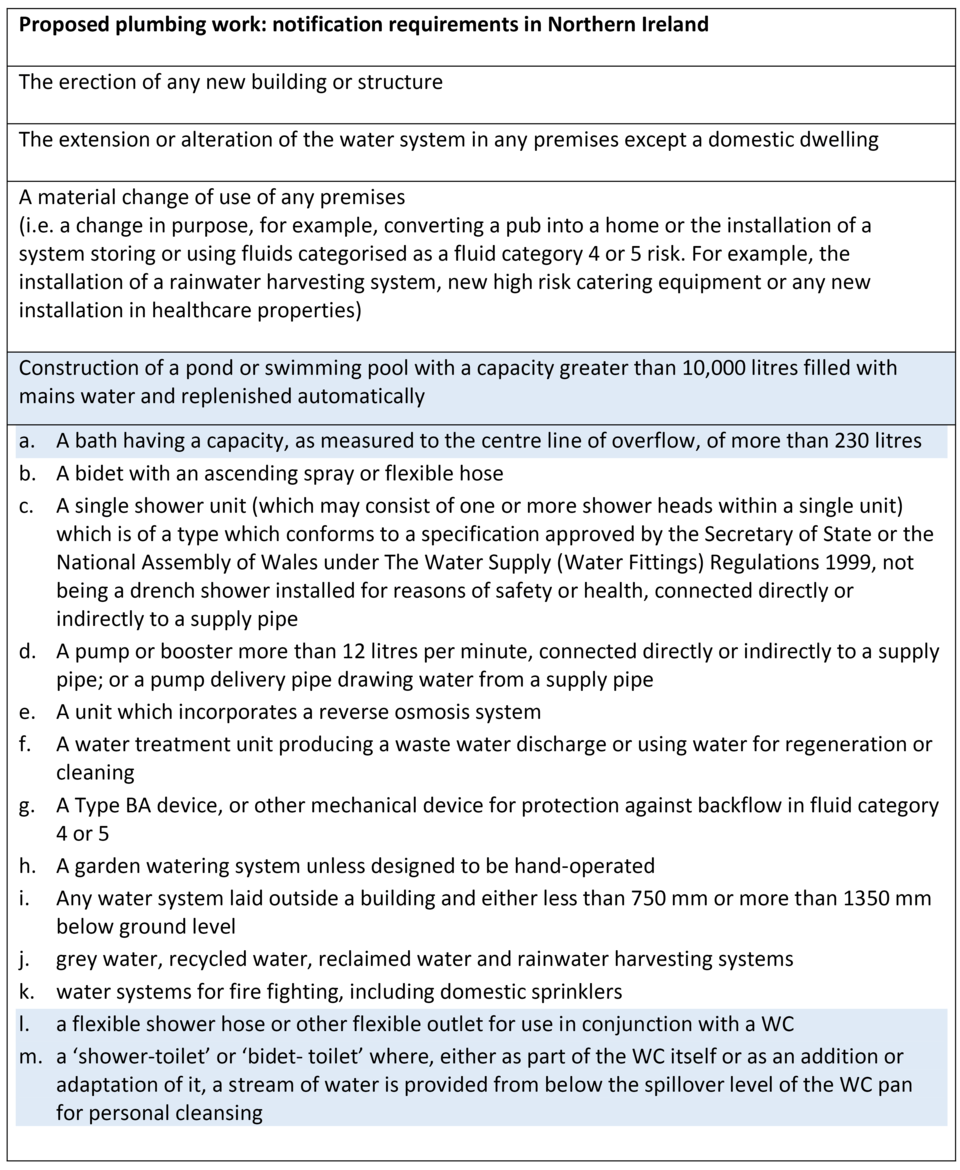

Although broadly similar there are differences in the notification requirements in England, Scotland, Wales and Northern Ireland. Any questions please contact the local water undertaker for advice.

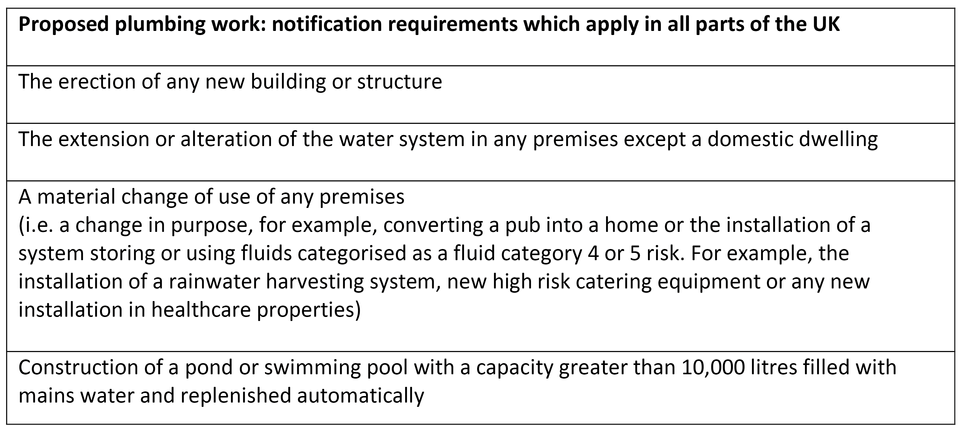

Notification requirements which are the same in England, Wales, Scotland and Northern Ireland.

Many water undertakers have their own notification forms and dedicated contact information which can be found on the water undertaker’s website and here. It is important to use the local water undertakers form especially when submitting electronically.

If the local water undertaker does not provide a form, for a notification to be valid it must include as a minimum:

The name and address of the person giving notice and, if different, the name and address of the person to whom the consent should be sent.

A description of the proposed work or material change of use.

The location of the premises and their use or intended use.

If using an approved contractor their name

Except for the items highlighted below a plan of those parts of the premises which relate to the proposed work and a diagram showing the pipework and fittings to be installed.

Scottish Water has its own notification form and dedicated contact as well as other information which can be found here .

Any questions please contact Scottish Water for advice.

Please note except for the items highlighted below a plan of those parts of the premises which relate to the proposed work and a diagram showing the pipework and fittings to be installed will be required.

Northern Ireland Water has its own notification form and dedicated contact as well as other information which can be found here .

Any questions please contact Northern Ireland Water for advice.

Please note except for the items highlighted below a plan of those parts of the premises which relate to the proposed work and a diagram showing the pipework and fittings to be installed will be required.

A material change of use is defined in the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland

It is a change in the purpose for which a premises is used or the circumstances in which water within that premises will be used, specifically the introduction of new systems or appliances which are categorised as posing a fluid category 4 or 5 risk.

For example:

The conversation of a house into a business premises or private business to a public building.

A change of business use

The installation of a new rainwater harvesting system, new high risk catering equipment or any new installation in healthcare.

For the purpose of the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland an approved contractor is a member of one of the following schemes.

Chartered Institute of Plumbing and Heating Engineering (CIPHE)

Scottish and Northern Ireland Plumbing Employers’ Federation (SNIPEF)

Providing:

Their scheme is recognised by the local water undertaker

The proposed work is not a material change of use

The scope of their membership covers the type of plumbing work undertaken

They comply with their scheme terms and conditions

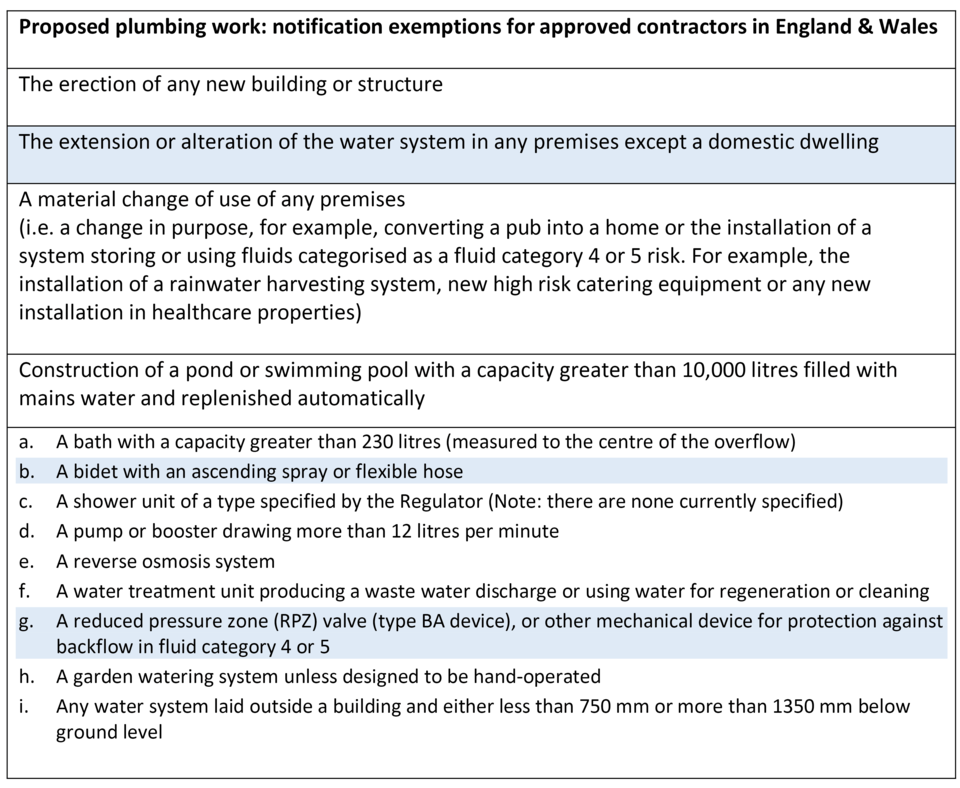

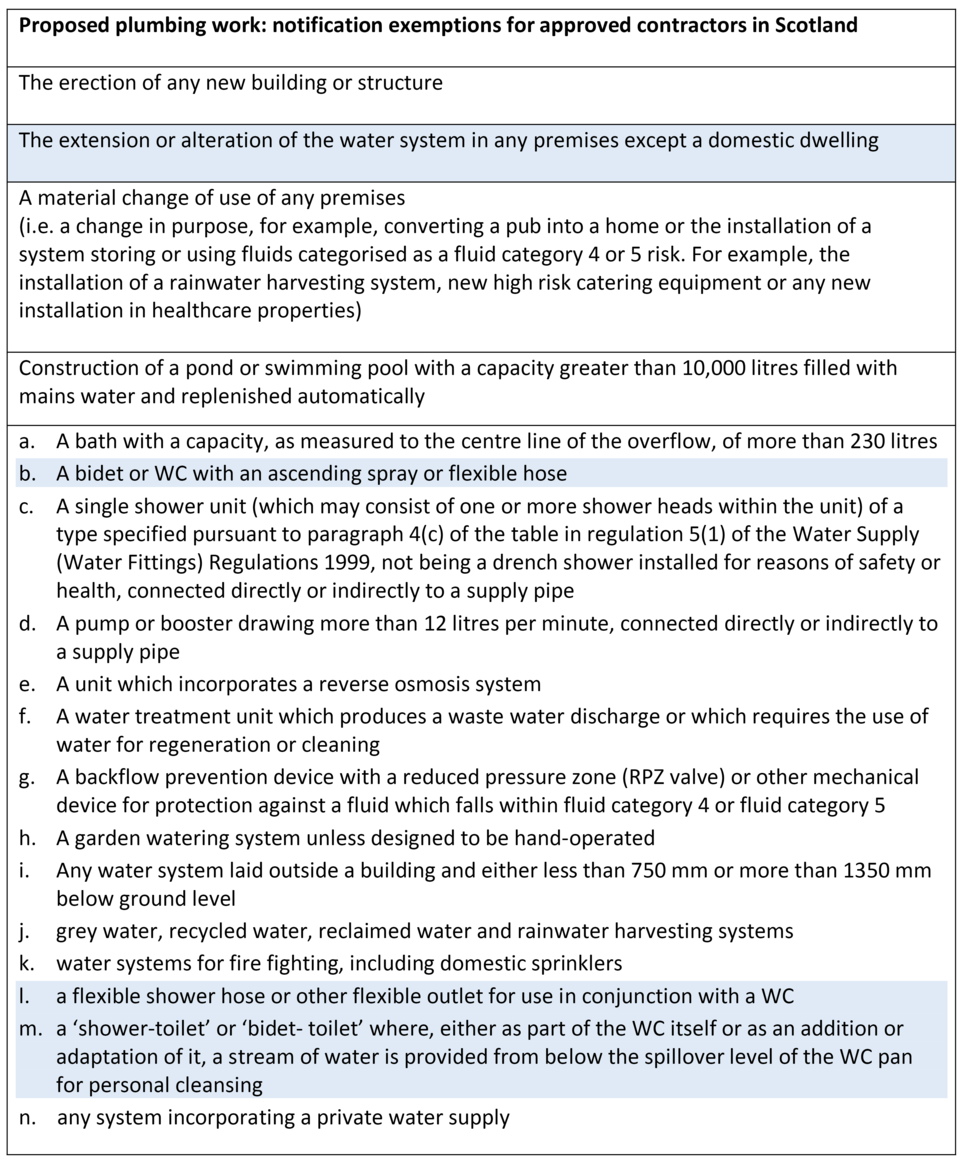

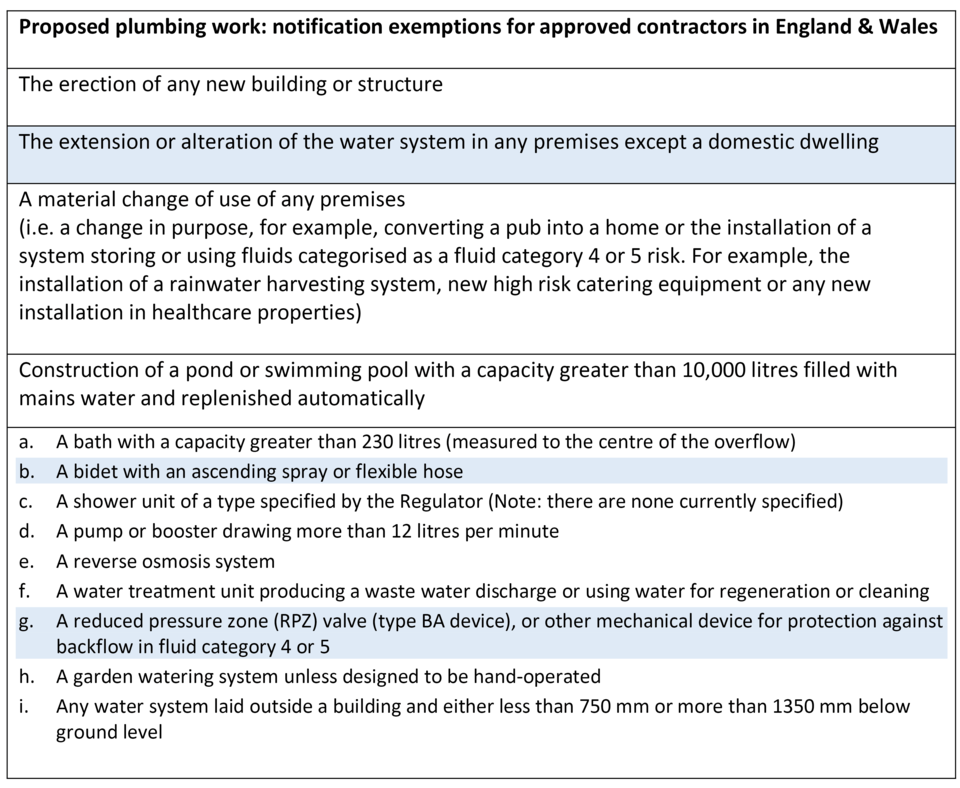

An approved contractor installing the items highlighted in the list below, may not have to provide advanced notification before starting work. However, on completion they will be required to send a certificate of compliance for the work to the local water undertaker as well as issuing one to their client.

Please note: notification exemptions for those approved contractors who are members of sector schemes is typically restricted to the alteration or extension of plumbing systems. For further information contact the scheme

Please note: due to both differences in notification requirements across the UK and variation in individual approved contractor schemes terms and conditions it is important to check whether advanced notification is required.

For the purpose of the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland an approved contractor is a member of one of the following schemes.

Chartered Institute of Plumbing and Heating Engineering (CIPHE)

Scottish and Northern Ireland Plumbing Employers’ Federation (SNIPEF)

Providing:

Their scheme is recognised by Scottish Water

The proposed work is not a material change of use

The scope of their membership covers the type of plumbing work undertaken

They comply with their scheme terms and conditions

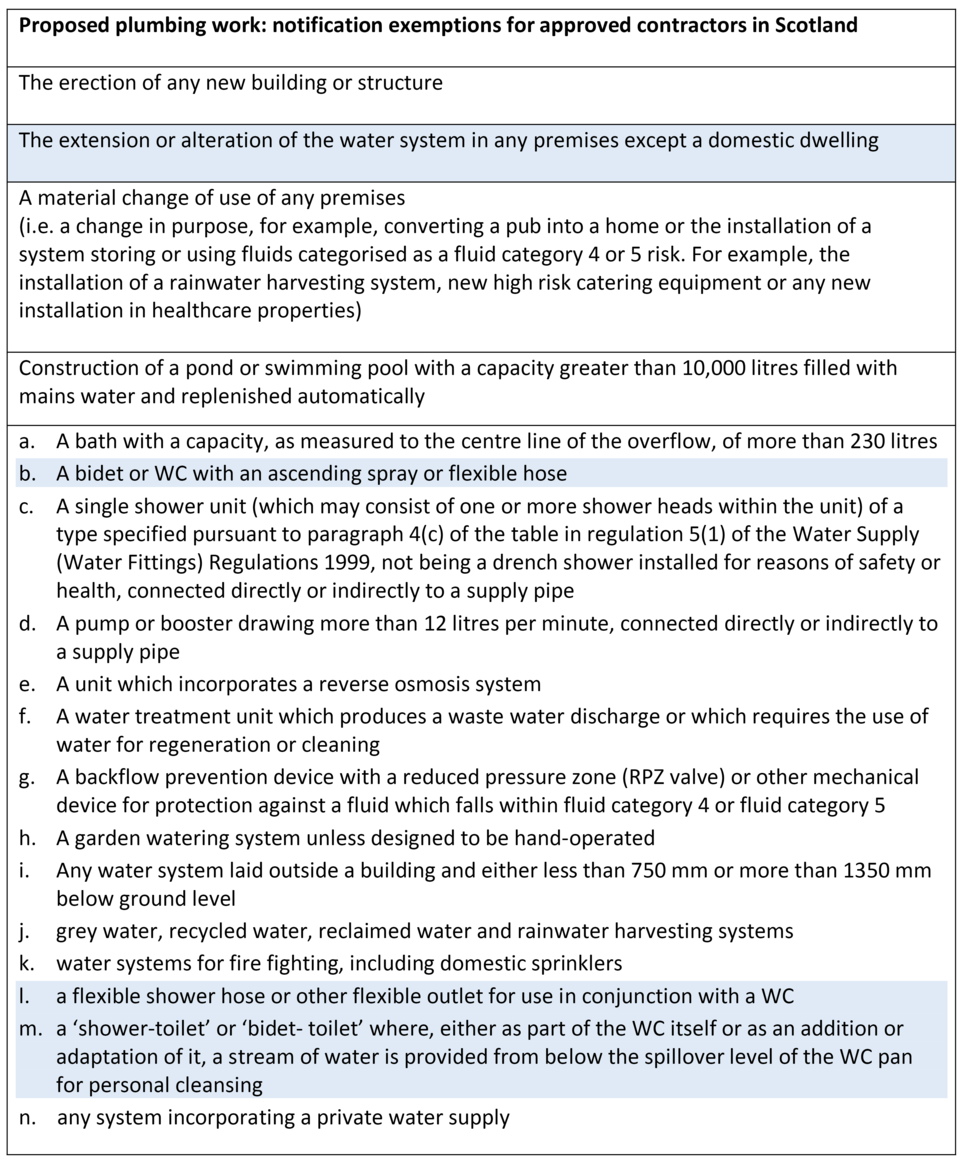

An approved contractor installing the items highlighted in the list below, may not have to provide Scottish Water with advanced notification before starting work. However, on completion they will be required to send a certificate of compliance for the work to Scottish Water as well as issuing one to their client.

Any questions please contact the Scottish Water for advice.

Please note: notification exemptions for those approved contractors who are members of sector schemes is typically restricted to the alteration or extension of plumbing systems. For further information contact the scheme

Please note: due to both differences in notification requirements across the UK and variation in individual approved contractor schemes terms and conditions it is important to check whether advanced notification is required.

For the purpose of the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland an approved contractor is a member of one of the following schemes.

Chartered Institute of Plumbing and Heating Engineering (CIPHE)

Scottish and Northern Ireland Plumbing Employers’ Federation (SNIPEF)

Providing:

Their scheme is recognised by Northern Ireland Water

The proposed work is not a material change of use

The scope of their membership covers the type of plumbing work undertaken

They comply with their scheme terms and conditions

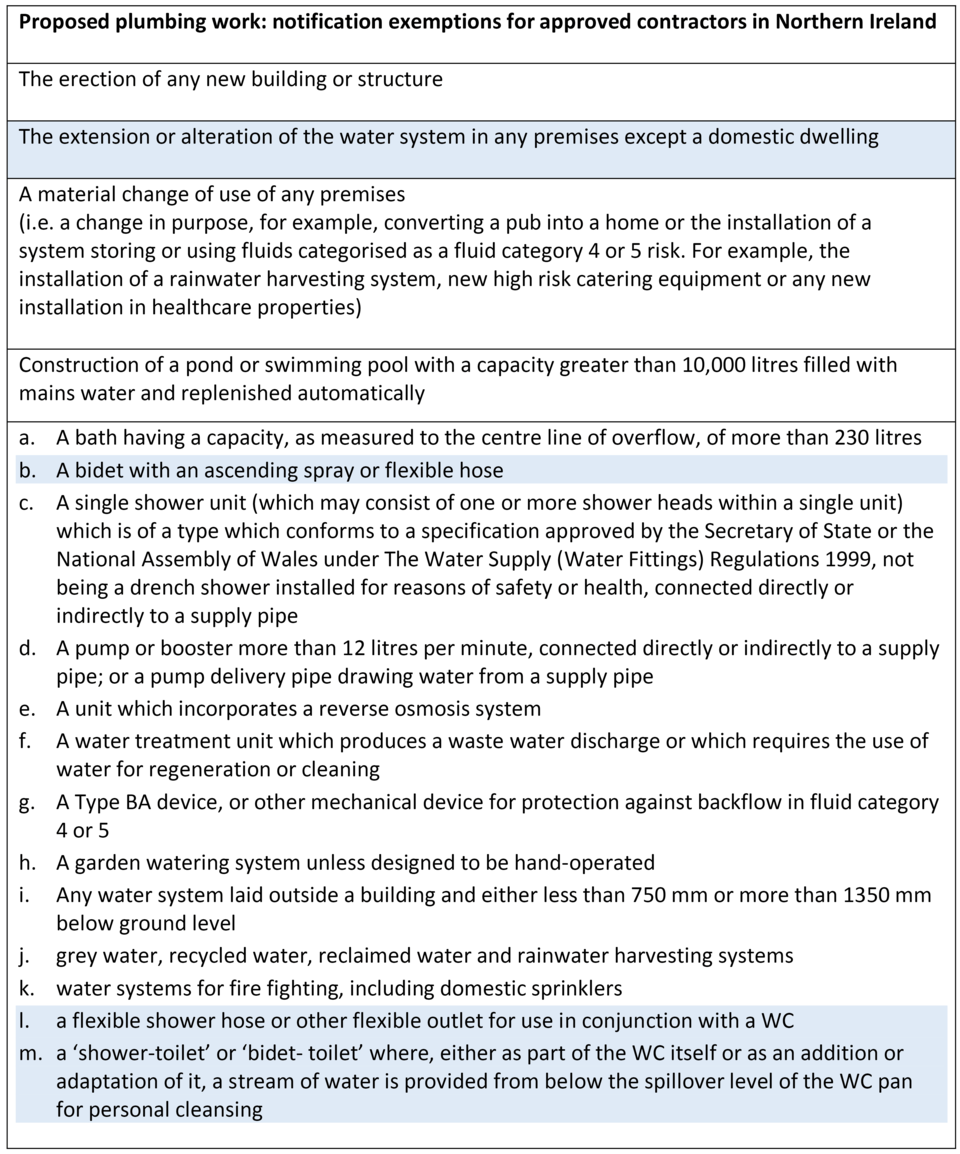

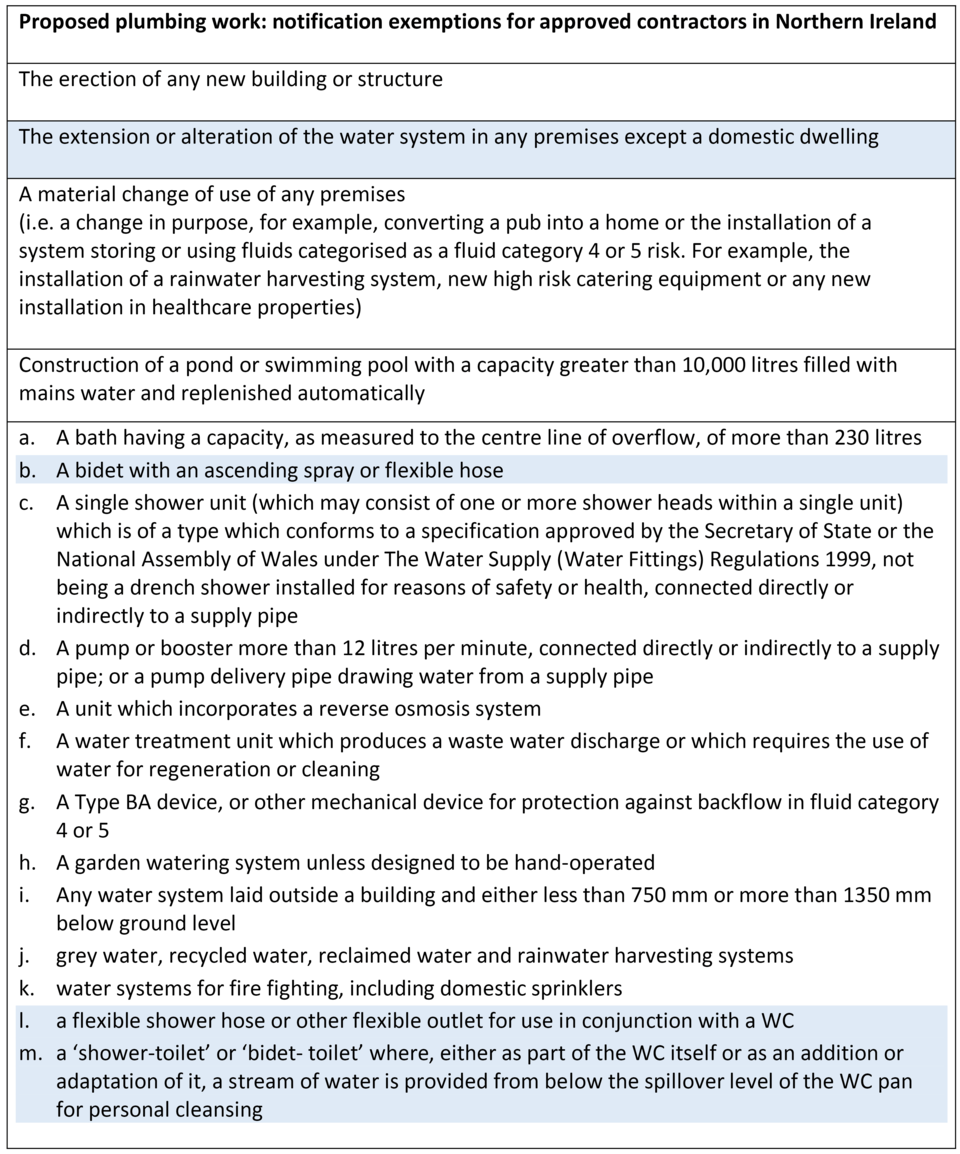

An approved contractor installing the items highlighted in the list below, may not have to provide Northern Ireland Water with advanced notification before starting work. However, on completion they will be required to send a certificate of compliance for the work to Northern Ireland Water as well as issuing one to their client.

Any questions please contact the Northern Ireland Water for advice.

Please note: notification exemptions for those approved contractors who are members of sector schemes is typically restricted to the alteration or extension of plumbing systems. For further information contact the scheme

Please note: due to both differences in notification requirements across the UK and variation in individual approved contractor schemes terms and conditions it is important to check whether advanced notification is required.

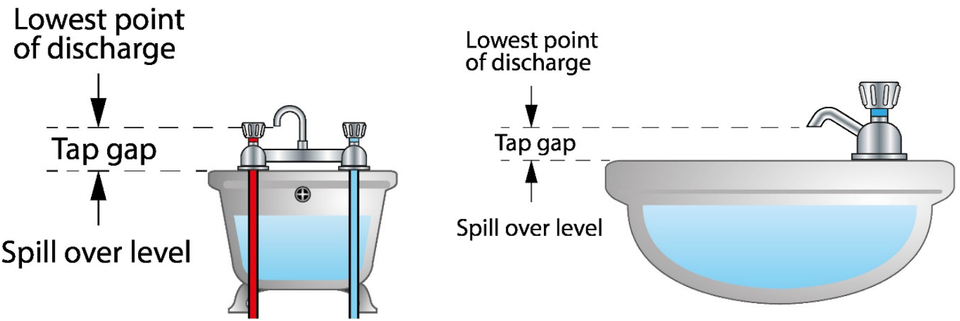

The requirement to notify the proposed installation of 'a pump or booster drawing more than 12 litres per minute, connected directly or indirectly to a supply pipe' applies to all pumps capable of delivering any flow rate greater than 12 litres per minute.

For example, a shower which is supplied with water through a pump (located either upstream or downstream of the mixing valve) capable of delivering more than 12 litres/minute.

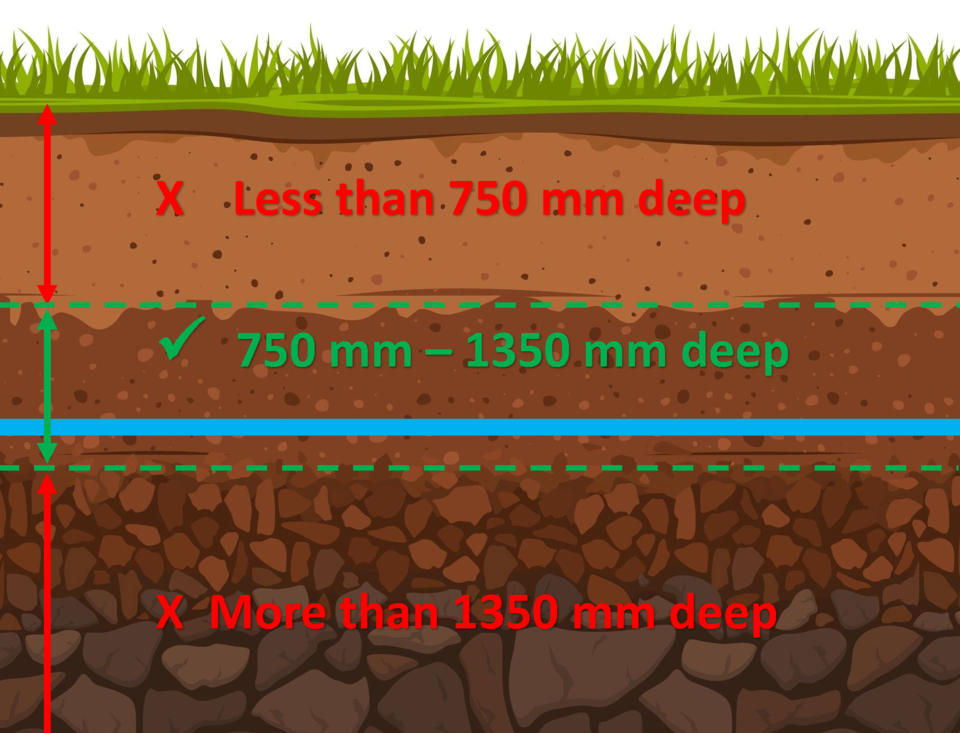

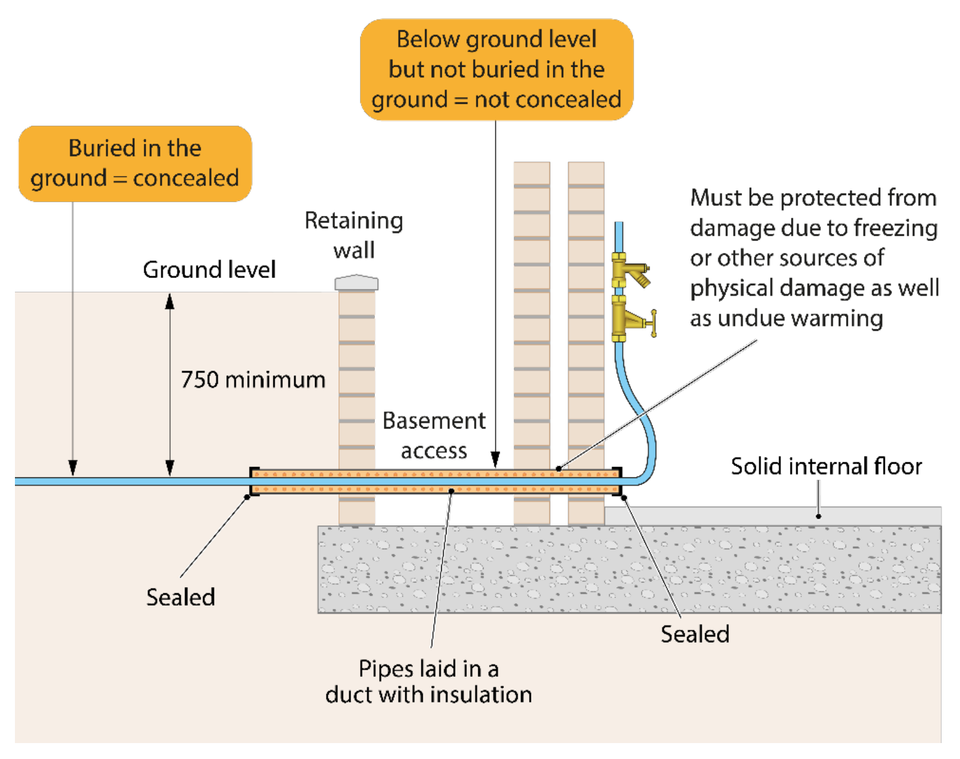

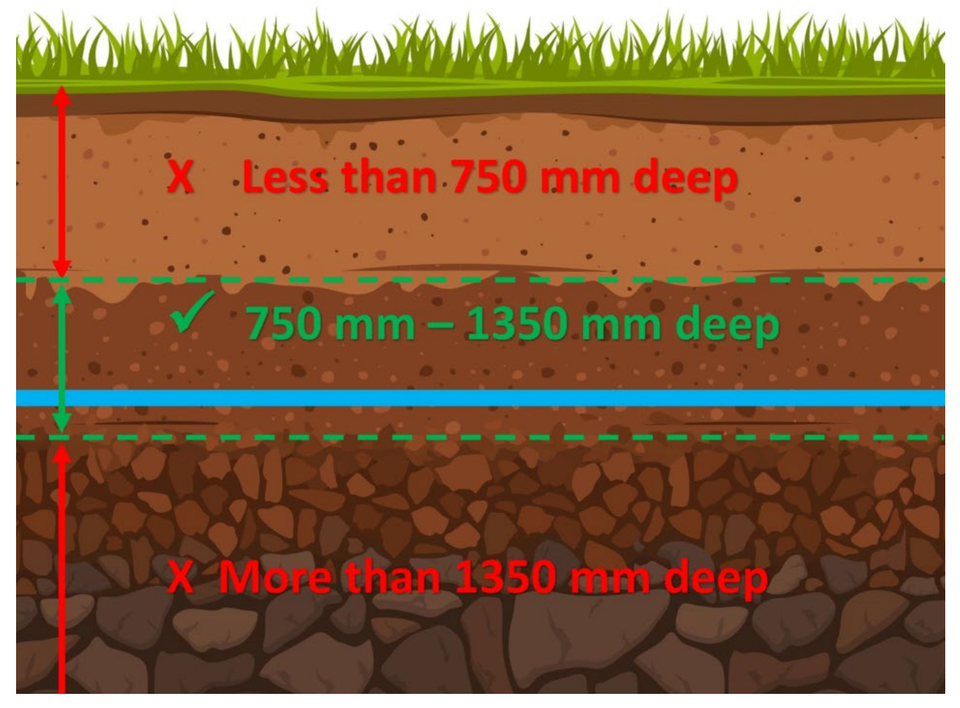

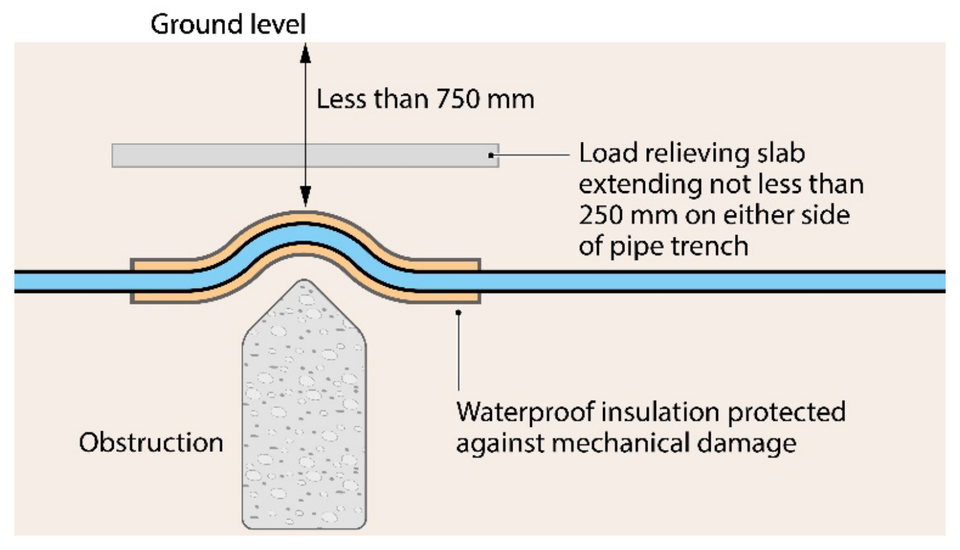

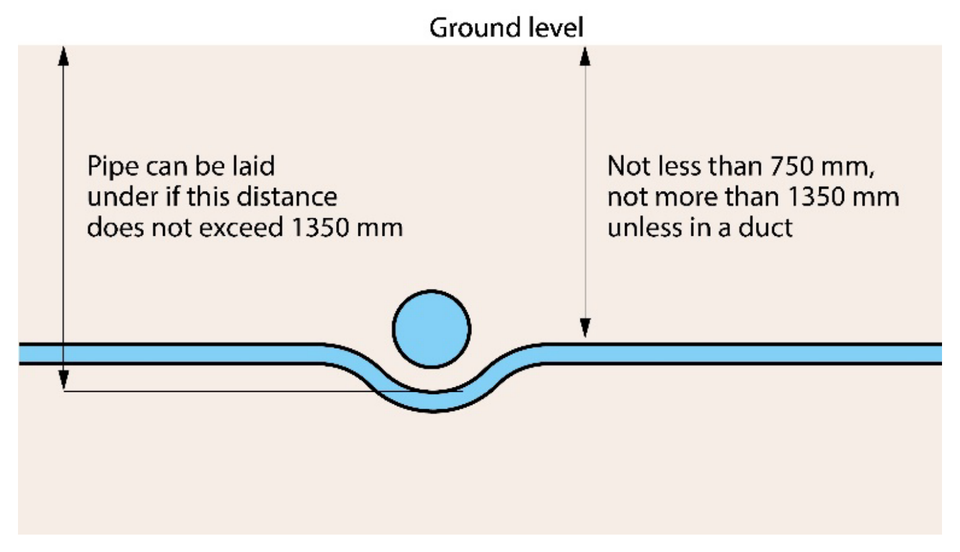

Pipework should be laid at a depth of not less than 750 mm (to limit the effect of freezing and mechanical damage) and no greater than 1350 mm deep. They should be embedded in non-abrasive materials. Where this cannot be achieved in all circumstances the consent of the local water undertakers must be obtained via notification.

Where the local water undertaker consents to pipework being laid at less than 750 mm it should be installed as deep as possible below ground level and protected against warming, freezing and mechanical damage (for example due to ground movement).

Pipework should not be installed above ground level is not permitted without the agreement of the local water undertaker.

To help prevent contamination and waste of mains water supplies the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland include specific requirements for water fittings. These include the legal requirement to be of an appropriate quality and standard for installation [regulation 4 (1)(a) & 4(2)].

This regulation requires water fittings, and water using appliances, to either:

Conform to an appropriate British Standard (or some other national specification which provides an equivalent level of protection and performance)

Or

Conform to a specification approved by the regulators

If the water conveyed by these fittings needs to be wholesome – drinking water standard - any non-metallic materials or components within the fitting or appliance which comes into contact with water must also conform to the current version of BS 6920 (or an equivalent).

Any questions please contact the local water undertaker for advice.

This is evidence to show a water fitting is of an appropriate quality and standard for installation.

Water undertakers will consider evidence of compliance provided on a case and site specific basis.

Whilst this evidence must satisfy another regulation [4(2)], water undertakers have no preference for, or require it to be in a specific form. Typically, they will consider declarations of performance issued against designated standards, product certification and test reports.

Please note:

Because a water fitting must comply with all parts of the regulations being of an appropriate quality and standard does not, of itself, guarantee compliance with the regulations.

The latest available edition or version of guidance or specifications should always be used.

In respect of equivalence water undertaker retain absolute discretion in assessing whether a national specification provides an equivalent level of protection and performance to that specified in an appropriate British Standard. For information regarding the equivalence of a performance specification please contact your water undertaker.

For further information please refer to Regulation 4(1)(a) compliance guidance and BS 6920 Compliance Overview.

Any questions please contact the local water undertaker for advice.

Some but not all appliances incorporate backflow protection which satisfies UK requirements, conformity with BS EN 61770 does not. If the backflow protection built in is not adequate the appliance must be supplied via an independent appropriate form of backflow protection.

Please refer to the 'Whitegoods' information leaflet for further information.

Establishing whether a water fitting is suitable for installation is dependent upon a number of factors including but not limited to:

Water fittings must be of an appropriate quality and standard

System design, things considered include but are not limited to compatibility:

with other water fittings within a plumbing system (e.g the potential for galvanic action)

system operational parameters (e.g. the maximum* and minimum pressure, temperature and flow the systems will be operating at)

Location specific factors, things considered include but are not limited to:

the environment (e.g. ground or airborne contamination, the risk of frost damage, corrosion or dezincification)

product installation requirements and/or constraints (e.g. installed where light is excluded or only above ground)

installation backflow risks (e.g. the need for backflow protection to be installed)

Requirements of schedule 2 as applicable.

If the proposed plumbing work is notifiable, the suitability of water fittings will be assessed as part of the notification process.

If the installation is not notifiable there remains a legal obligation for the installer and premises owner or occupier to ensure the plumbing work is fully compliant with the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland. Therefore, if in doubt, contact the local water undertaker for advice.

*Please note all water fittings must be capable of withstanding an internal water pressure of not less than 1½ times the maximum pressure it will be subject to in operation.

Providing appropriate and adequate backflow protection against the highest level of risk downstream is installed, an installation not used to supply water for drinking, bathing, food preparation or cooking purposes is exempt from complying with schedule 2 paragraph 2(1).

Please note the backflow protection required needs to be assessed by the local water undertaker and other requirements of the water fittings regulations/byelaws continue to apply.

When designing a compliant plumbing system a number of factors need to be considered, including but not limited to:

Avoiding the risk of contamination or damage resulting from the environment in which the system is to be installed or due to the design itself.

The required and attainable supply pressure and other operational parameters

User expectations and whether these are achievable

Suitability of water fittings for use

Providing appropriate, adequate backflow protection.

Water efficiency

Limiting waste.

Useful sources of information include BS EN 806 and BS 8558

To help prevent waste and contamination all pipe and fittings systems must be of an appropriate quality and standard and suitable for the circumstances in which they will be used.

Before installing a pipe and fittings system key considerations will include but are not limited to:

The compatibility of the pipe and fittings. For example, to ensure connections are watertight and configured to prevent galvanic action.

Whether the pipework is to be installed above or below ground

Where the pipework is to be installed. For example, in contaminated ground, in a duct and potentially exposed to construction materials and/or water vapour, somewhere exposed to sunlight or sources of heat.

What water temperatures and pressures the pipework will be exposed to. For example, hot or cold water only, heating systems, maximum operating pressure and thermal shock.

In the case of metallic water fittings, the possibility of corrosion due to galvanic action and dezincification.

Useful sources of information include BS EN 806 and BS 8558

Please note:

All water fittings should be resistant to corrosion. In the case of mechanical backflow prevention devices and metallic fittings which are not going to be readily accessible, in addition to being corrosion resistant these should be manufactured from materials which are not susceptible to dezincification. For example, gunmetal or CR brass.

As non-metallic pipe and fittings can be affected by sunlight and/or allow ingress of light, which is known to promote the growth of algae, consideration should be given to whether protective measures to exclude light are necessary.

Adhesive joints are not acceptable below ground.

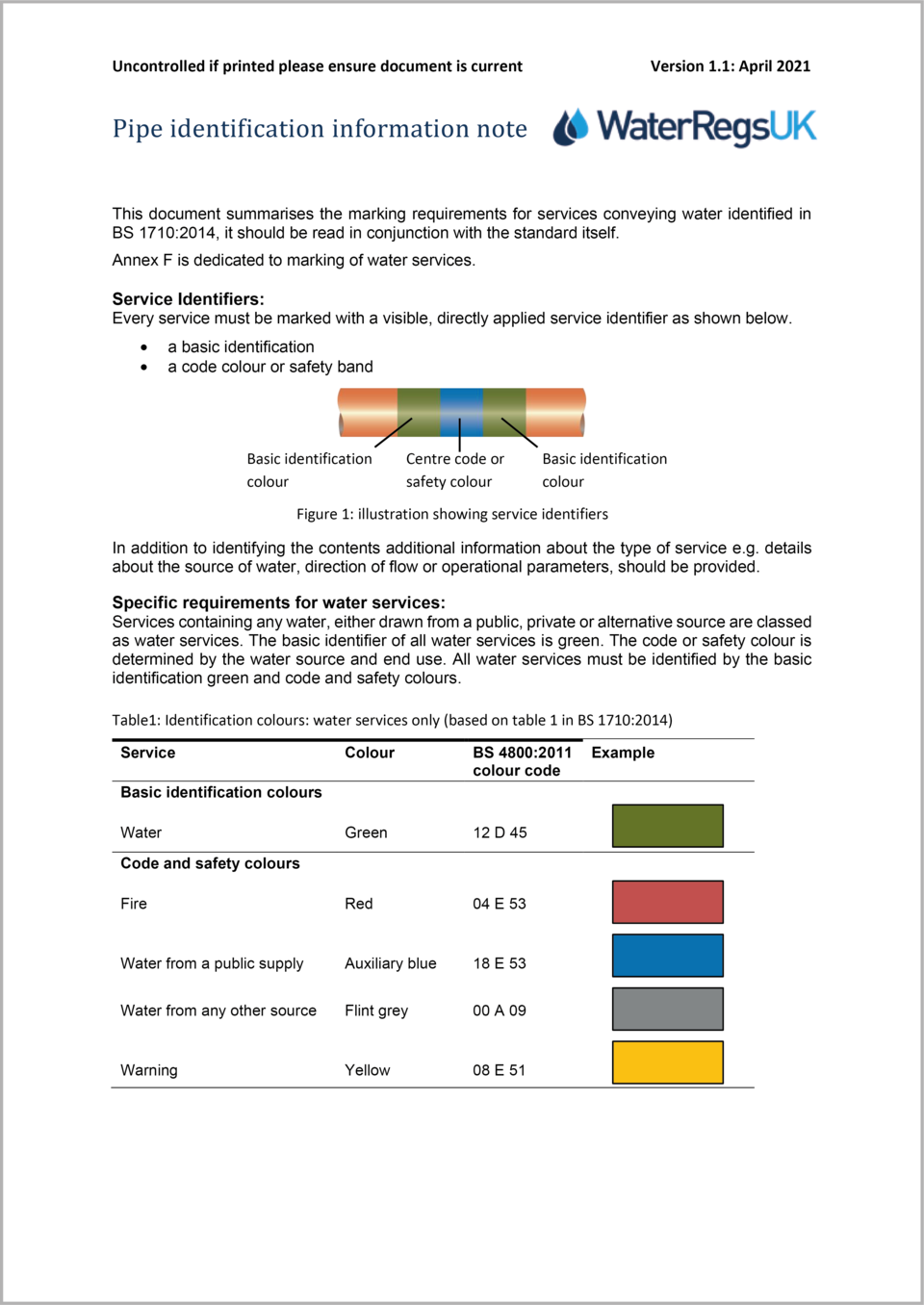

Irrespective of what fluid is being conveyed all pipework, whether installed above or below ground, should be marked in accordance with the latest version of BS 1710.

To identify what parts of a plumbing system they control, servicing valves should be labelled.

For further information please refer to the pipe identification information leaflet

One way is to measure the supply pressure at a tap directly supplied from the mains at a time when there is little demand, such as at night.

Please note:

This will not take into consideration any transient or surge pressures which may be generated within the system. For example water hammer resulting from the rapid closure of a valve within the system.

Water fittings must be able of accommodating 1½ times the maximum operating pressure.

To minimise the risk of contamination resulting from microbial growth and wastage due to taps left to run, cold water storage and distribution systems should be designed and installed to maintain a temperature not exceeding 20oC.

Plumbing systems should be designed and installed to ensure there is regular flow through.

To prevent undue warming, it is good practice to insulate both hot and cold water pipework. Unless it is adequately protected water fittings should not be installed where it could be exposed to heat sources, such as other services or sunlight.

For further information please refer to BS EN 806, BS 8558 and HSE Legionella ACOP.

Joints on concealed pipework are likely to lose their integrity over time and therefore should only be considered where unavoidable.

To prevent waste there needs to be provision to access any joints or water fittings which require maintenance, such as backflow prevention devices, valves which control the flow and any other operational fitting.

To minimise waste when maintaining or replacing water fittings (including water using appliances) servicing valves should be installed as close as practicable to any part of a plumbing system performing a specific task.

Similarly to minimise waste when draining down systems not in use servicing valves and drain taps should be installed as close as practicable to any part of a plumbing system performing a specific task.

Servicing valves should be labelled to indicate what parts of a plumbing system they control.

In the case of inlet valves supplying toilet or urinal flushing cisterns and cold water storage, consideration should be given to pressure surges resulting from operation of the servicing valve.

Please note: drain taps should not be buried or covered with soil, or installed so that they are submerged, or likely to be submerged.

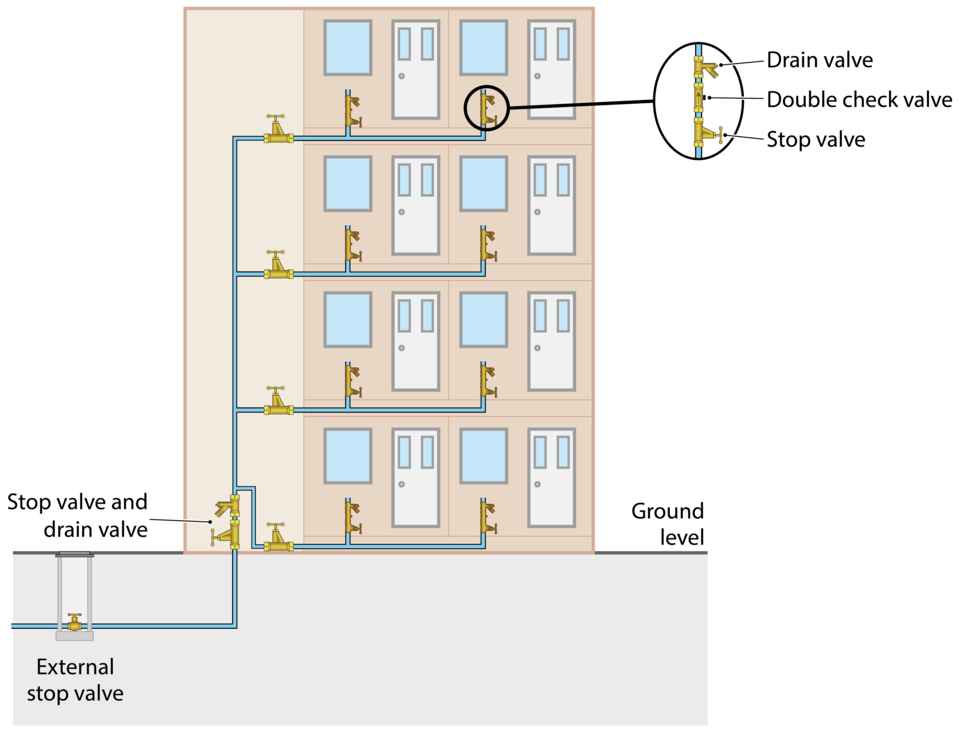

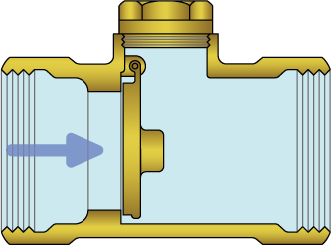

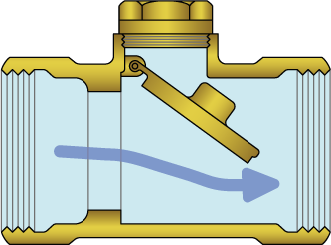

Stop valves isolate the supply to premises.

To help minimise waste stop valves should be labelled to indicate what parts of a plumbing system they control.

Stop valves should be installed on the supply pipe in a readily accessible location either inside or immediately outside the premises.

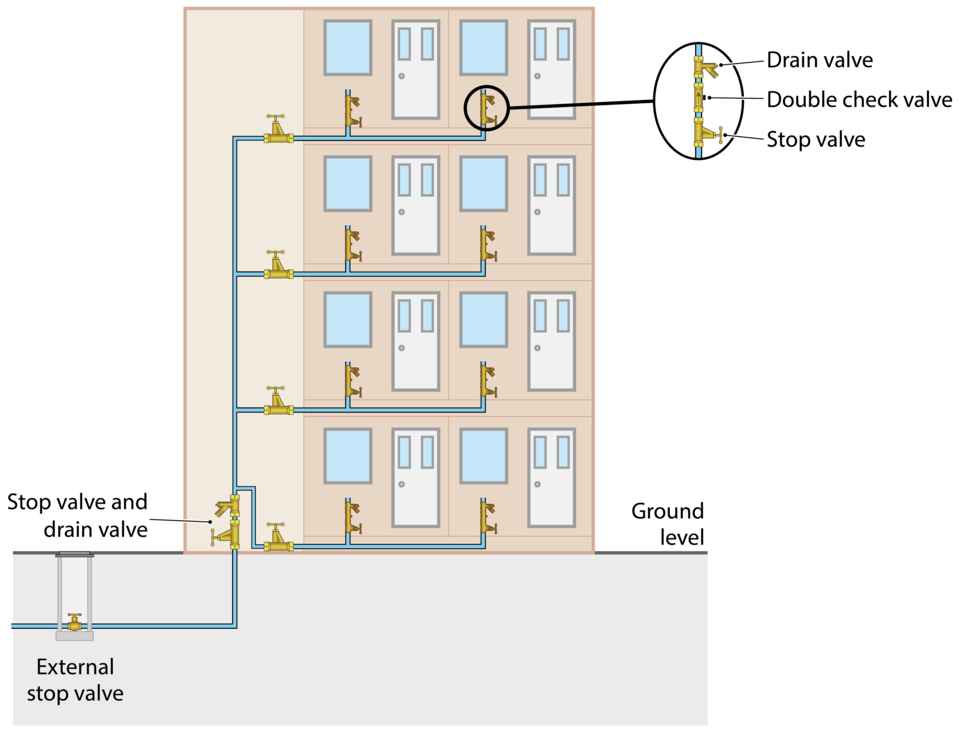

In the case of properties with multiple occupants, such as a block of flats, in addition to the customers own stop tap, a stop valve for maintenance or communal use should be installed.

When selecting a stop valve for use by owner/occupiers consideration should be given to ease and speed of operation, including the effect of sudden changes in supply pressure.

Please note: the illustrations above are examples of acceptable locations for stop valves. Whilst not shown other requirements apply, including but not limited to the installation of drain taps, servicing valves and backflow protection.

For further information contact the local water undertaker.

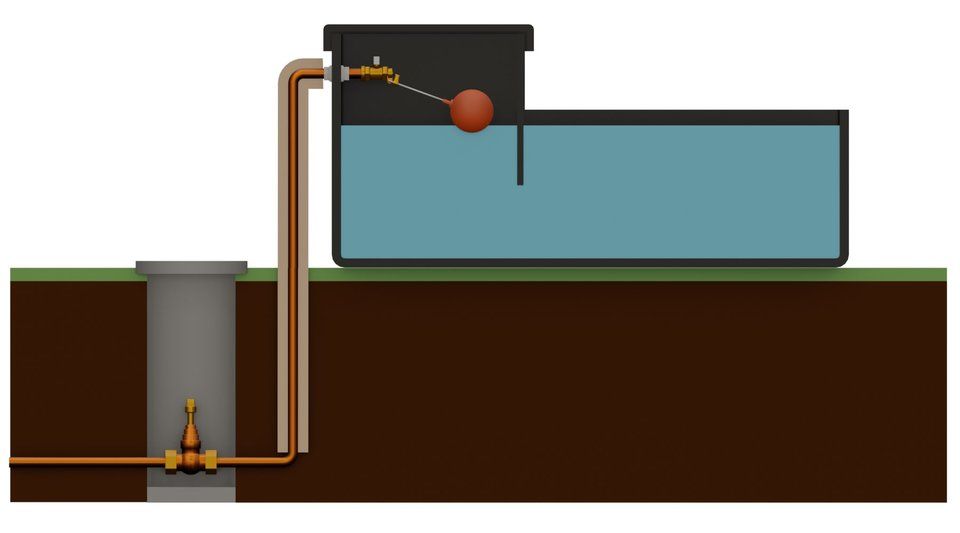

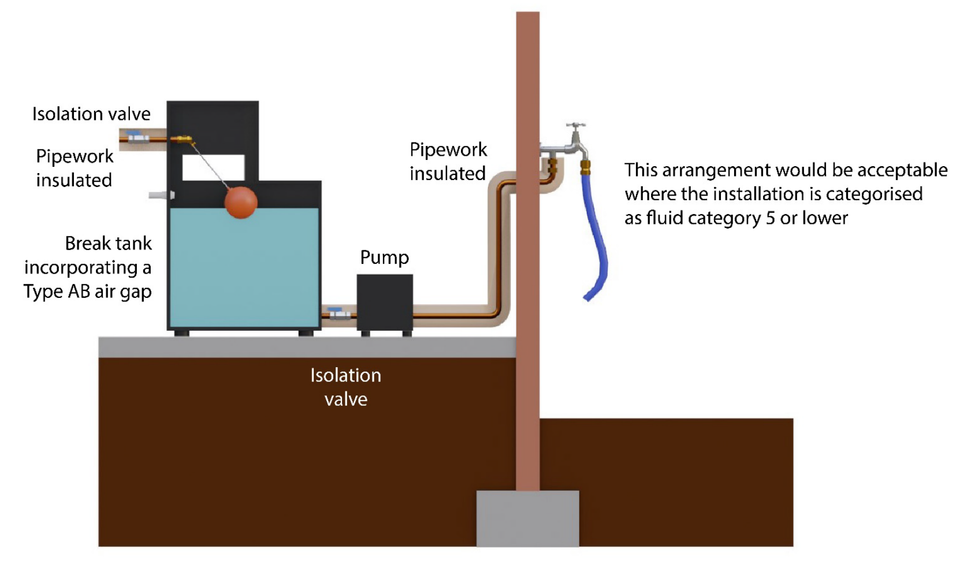

Owners/occupiers should always ensure the local water undertaker is aware if a premises has both a mains drinking water and alternative water supply, such as a borehole or rainwater.

No. Alternative water supplies should never be directly connected to the mains drinking water.

Where mains water and other water sources, such as rainwater, recycled water, river water and borehole supplies, combine it is essential to notify the relevant water undertaker to ensure adequate backflow protection arrangements are installed.

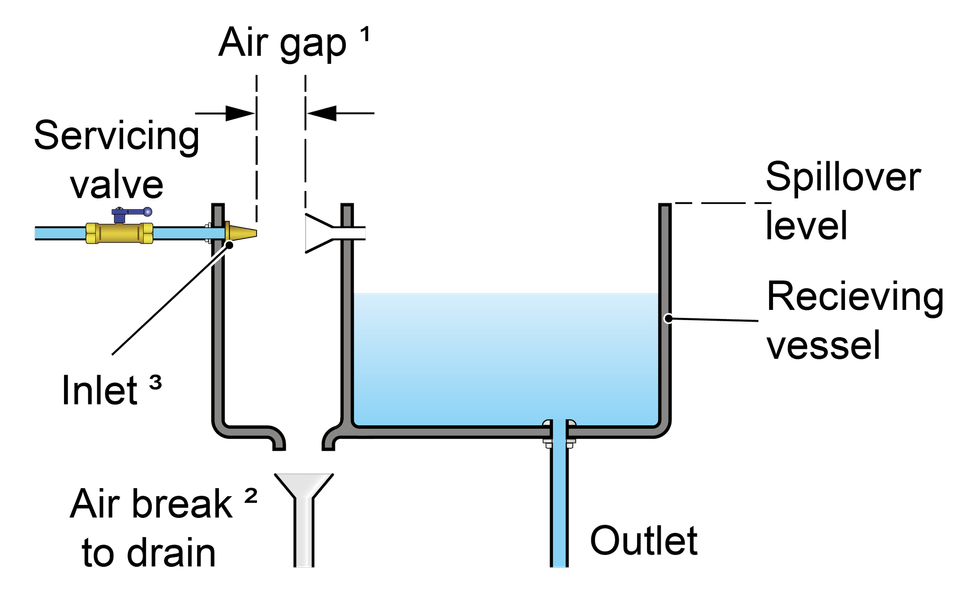

The only legal and safe way to combine mains and another source of water is to use an arrangement called a break tank which enables separation of supplies. Typically, this is done using a Type AA or Type AB air gap the key features being:

An unrestricted or weir spill over

The pipework supplying the mains water must be external to the tank

The mains water feed must discharge at a higher level than and maintain a minimum clearance (twice the internal diameter (2D) of the supply pipework or 20 mm whichever is the greater) from those another sources

The water in the tank should not come into contact with the mains water inlet for example as a result of splashing.

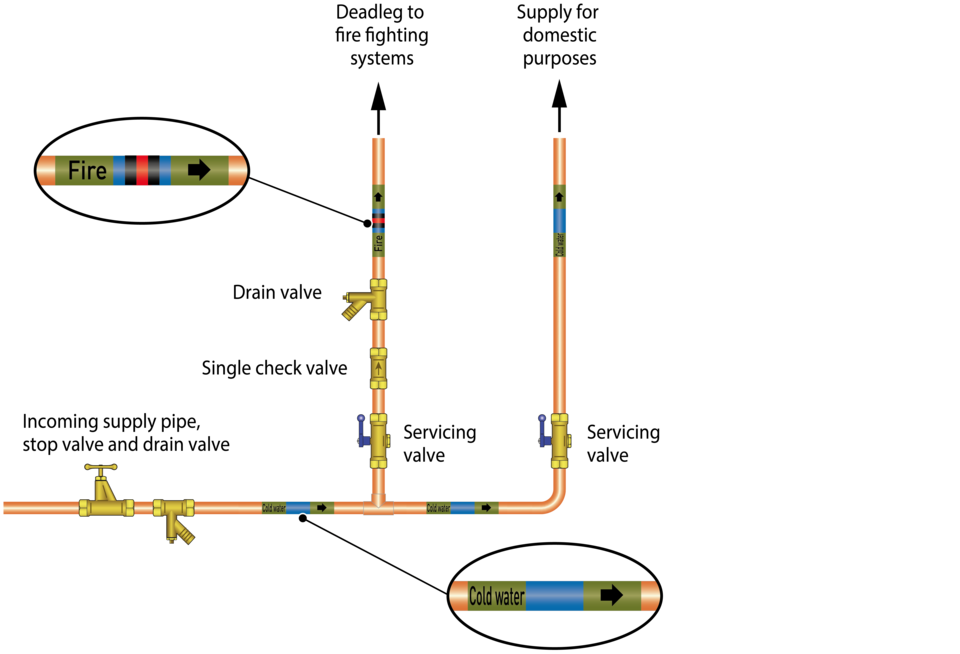

‘Dead leg’ or ‘blind end’ is a term used to describe a section of pipework (leg) containing water which is not turned over i.e. the water is stagnant (dead). For example, pipework which supplied a system that has been removed or is no longer in use (redundant).

Yes, dead legs should be removed as they are a potential source of contamination. If the dead leg cannot be completely removed any blind end should be as short as possible.

All plumbing systems should be designed to ensure a steady through flow of water. For pipework supplying fittings which are used infrequently i.e. fire supplies or water reuse systems with a back-up supply, appropriate backflow protection should be installed as close as reasonably practicable to the mains or supply/distributing pipe.

Yes.

The pressure testing requirements specified in BS EN 806 recommends that plumbing installations and fittings be tested at 1.1 times the maximum working pressure rather than the 1.5 times required by the Water Supply (Water Fittings) Regulations, Byelaws in Scotland.

However due to the terms and definitions applied rather than advocating a lower pressure test than that required by the UK national requirements BS EN 806 actually recommends a slightly higher test pressure. With the result that should an installation be designed to satisfy the pressure test recommendations given in BS EN 806, then it will by default comply with those of the Water Fittings Regulations /Byelaws

Summary of requirements of BS EN 806:

BS EN 806: Part 1 defines maximum design pressure (MDP) of a system as:-

‘the maximum hydrostatic pressure at which the potable water installation is designed to work’

BS EN 806: Part 2 covers design, clause 3.4.2 which covers strength states:-

‘To ensure adequate strength, all components of the system shall be designed to meet the test pressure requirements of the local and national laws and regulations. The test pressure shall be at least 1.5 times the allowable maximum operating pressure (PMA).’

Therefore the maximum design pressure should be at least 1.5 times the maximum operating pressure.

MDP = 1.5 x maximum operating pressure

To comply with the requirements of schedule 2 paragraph 15 (1) a backflow prevention device or arrangement rated to at least fluid category 2 must be installed Fittings Regulations/Byelaws require the system to be pressure tested at:-

1½ x 5 bar =7.5 bar

BS EN 806 recommends a test pressure of:-

1.1 x maximum design pressure (MDP)

where

MDP = 1½ x maximum operating pressure

1.1 x [1½ x 5 bar] = 8.25 bar

The recommended distances between utilities can be found in the latest National Joint Utilities Group (NJUG) guidelines. Where these dimensions and depths cannot be achieved protective measures will be required.

All pipework whether installed above or below ground should be marked in accordance with the requirements of the latest version of BS 1710.

If the installation of the pipework is notifiable, under regulation 5 of the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland, installation advice should be provided as part of the notification process.

If it is not notifiable there remains a legal obligation for the premises owner or occupier to ensure the plumbing work is fully compliant with the water fittings regulations, byelaws in Scotland.

There are a number of design requirements for troughs and animal drinking bowls including:

The trough/drinking bowl must be watertight

An inlet arrangement supplying water to the trough/drinking bowl must:

Be of an appropriate quality and standard to control the flow

Be rigidly and securely fixed

Be protected against environmental, accidental and animal damage

The supply to the trough/drinking bowl must be protected by a suitable form of fluid category 5 backflow protection.

The easiest way to prevent backflow from happening is to ensure a suitable gap is maintained between the water inlet feeding the trough or drinking bowl and the overflow or spill over level. Alternatively, where multiple troughs or drinking bowls are supplied from the same distribution pipe, a break tank arrangement fed via a Type AA, AB or AD arrangement could be used to provide backflow protection.

To minimise waste when maintaining or replacing components a servicing valve should be installed as close as practical to the inlet arrangement.

Stop valves which isolate trough(s)/drinking bowl(s) will also help to minimise waste in the event of a leak and enable pipework and troughs/drinking bowls not in use over the winter to be isolated and drained, which will help to prevent frost damage. Don’t forget to label which troughs/drinking bowls a stop valve controls.

All water fittings must be protected against environmental, accidental, and animal damage . For example, pipework laid at a depth less than 750 mm must be protected. This includes any above ground and outside the thermal envelop, which must be ducted, insulated and sealed. Sealing will help to prevent damage by rodents which is a common cause of leaks. In the case of troughs fitting a raised service box, which does not compromise any air gap providing backflow protection, will protect the inlet arrangement.

To stop the inlet from becoming submerged and prevent waste of water as a result of continuous spillage, troughs and drinking bowls should be installed level.

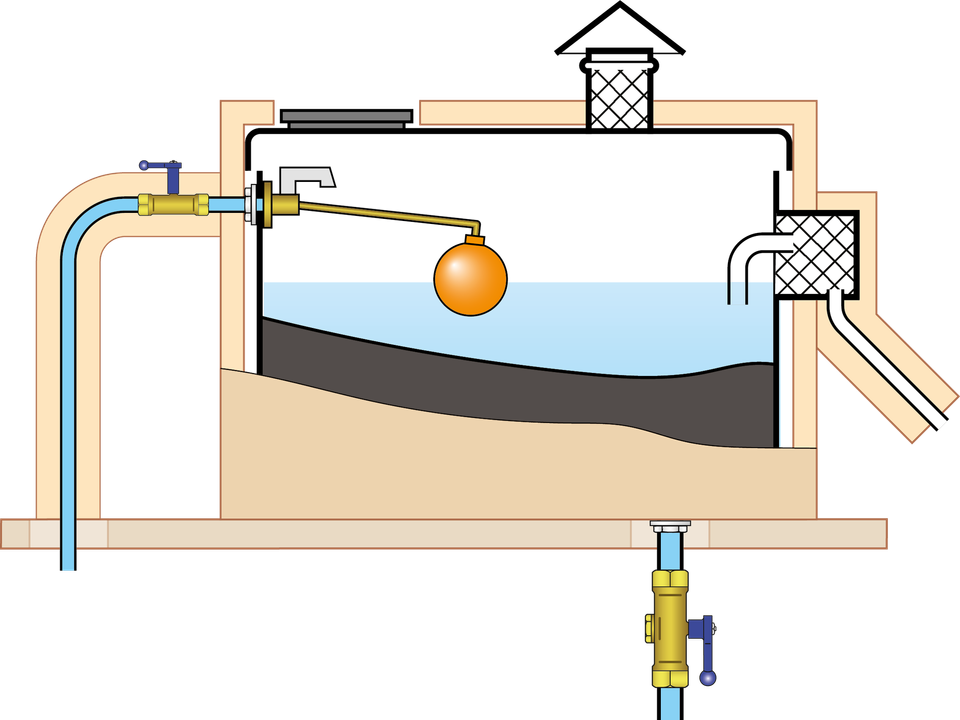

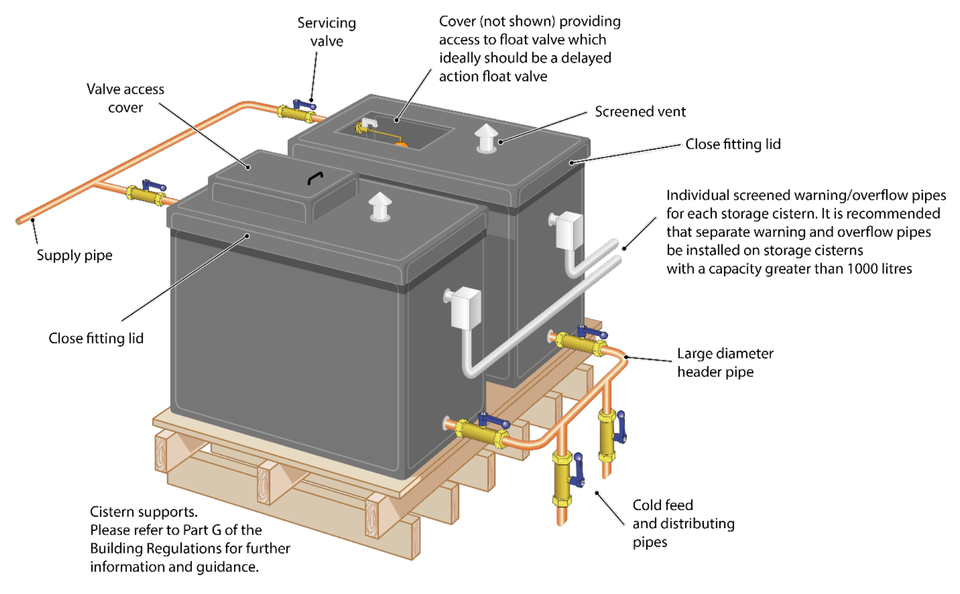

Where the water stored in a cistern has to remain wholesome it is important to minimise the risk of contamination. Key to this is making sure the water is stored for as short a period as possible. This is achieved through a combination of design and maintenance features and correctly sizing the cistern to ensure the regular turnover of the stored water and avoid stagnation as well as any deterioration of water quality.

Factors which should be considered when sizing a cistern include occupancy (intended and actual) and usage. Suggestions for storage capacity are given in BS EN 806-2.

All components making up and used within a cold water storage cistern must be of an appropriate quality and standard

All non-metallic materials in contact with water, including any surface where condensate forms, must conform with the current version of BS 6920 (or an equivalent).

Cisterns should be watertight and where appropriate lined or coated with suitable impermeable materials.

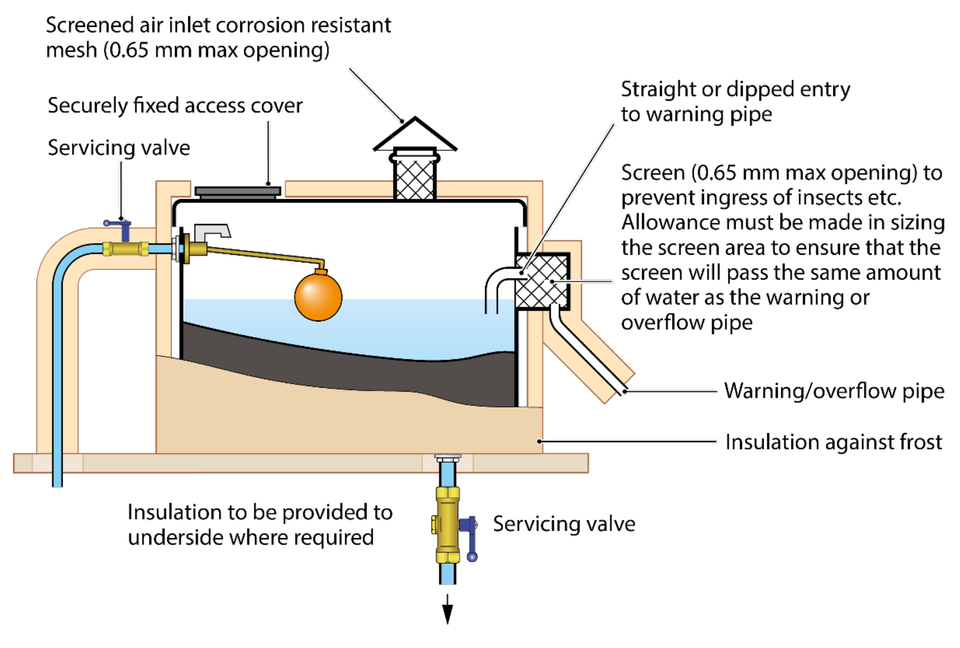

In addition to an inlet, outlet, overflow pipe and warning arrangement a cistern should have a rigid close fitting and securely fixed lid or cover. Cisterns, and their lids, should be made of materials which do not shatter or fragment when broken.

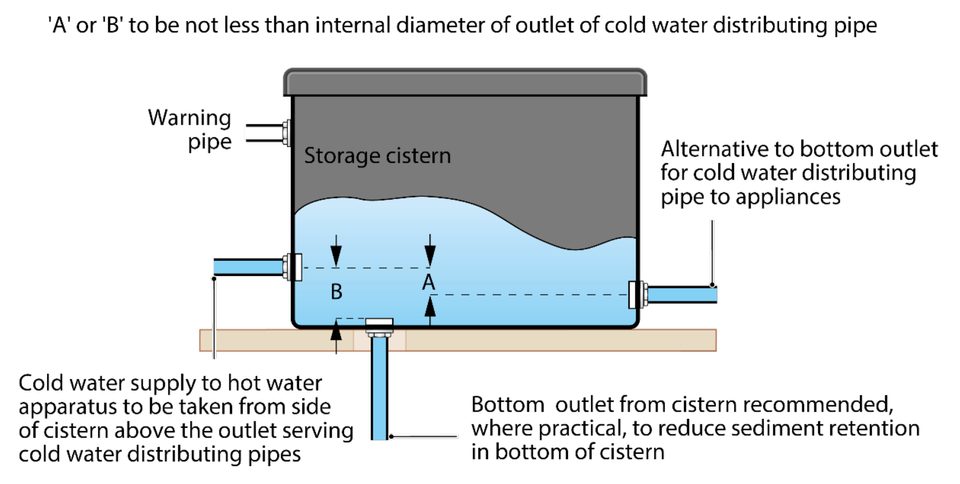

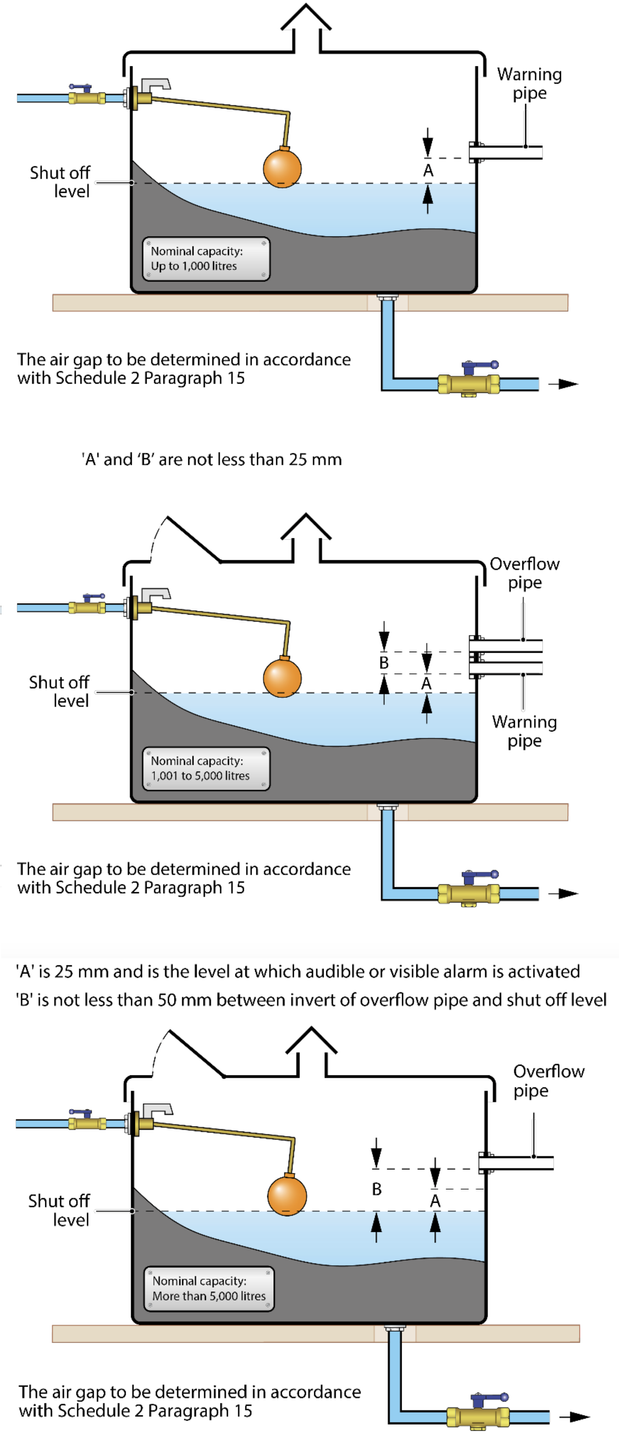

An inlet valve must be fitted. This should be securely and rigidly fixed and must shut off the flow at a set level within the cistern. Typically, this level is a minimum of 25 mm below the overflow but should be increased to a minimum of 50 mm if there is no warning pipe. Where a float operated valve is to be used, this must be capable of being adjusted to ensure that the inlet valve closes at a defined level.

Where the inlet forms part of an air gap arrangement intended to prevent backflow, the inlet valve should not come into contact with the contents of the cistern as a result of splashing or foaming. If this occurs the inlet valve should be adjusted to increase the air gap.

Float operated valves are generally, but not always used for controlling the flow of water into a cistern. Electrically or pneumatically operated valves are also an acceptable form of valve for controlling the inlet flow. In all cases the method of installation must be suitable for the specific installation and comply with all aspects of the appropriate water fittings regulations/byelaws.

Transient pressure increases or surges (water hammer) may be caused by the rapid closure of valves, resulting in a sudden stop or change of water flow. To keep pressure surges within reasonable limits and prevent damage to water fittings hydro-pneumatic accumulators, surge arrestors or pressure reducing valve can be installed.

In addition to any backflow protection required by the local water undertaker a servicing valve must be installed on the inlet adjacent to the cistern and outlet to facilitate maintenance and minimise waste.

To encourage mixing and prevent areas of stagnation or ‘short circuiting’ within the cistern where practical the cistern inlet and outlet should be on opposite sides of an appropriately sized cistern. Where multiple cisterns are linked; inlets and outlets need to be carefully balanced to promote a good turnover of water in each cistern.

Where practicable all outlets from a storage cistern should be located at the bottom of the cistern and to encourage mixing and prevent areas of stagnation or ‘short circuiting’ within the cistern on the opposite side to the inlet.

All outlets from cold water storage cisterns, except vent pipes, overflow pipes and warning pipes, should be fitted with a servicing valve as close to the cistern as is reasonably practicable.

Every cold water storage cistern must be fitted with an overflow pipe.

To help minimise waste a suitable means of warning of an impending overflow must also be installed. A warning pipe is commonly used for this purpose, but with the local water undertaker’s agreement alternatives may be fitted. Although usually separate a combined overflow/warning pipe may be accepted on cisterns with a capacity of 1,000 litres or less.

Overflow and warning pipes must be positioned so as to exclude light and insects. A screen with a mesh size no greater than 0.65 mm (opening) is typically used to prevent the ingress of insects and other foreign bodies. If an insect screen is installed it should be vertically and removable.

Overflow and warning pipes should be installed on a downward inclined plane and not discharge into any other cistern.

The discharge from the overflow and/or warning pipe should be safe and conspicuous. If discharging to drain a visible air brake, giving fluid category 5 backflow protection in the form of an air break to drain conforming to the design specification given in EN 1717 must be installed.

If a common warning pipe is used the location of the cistern overflowing must be readily identifiable. A warning/overflow pipe should be at least 19 mm (internal diameter) and capable of accommodating all possible flow rates i.e. the maximum inflow under fault conditions. The effect of any screen on the nominal flow capacity must be taken into account when determining the size of an overflow.

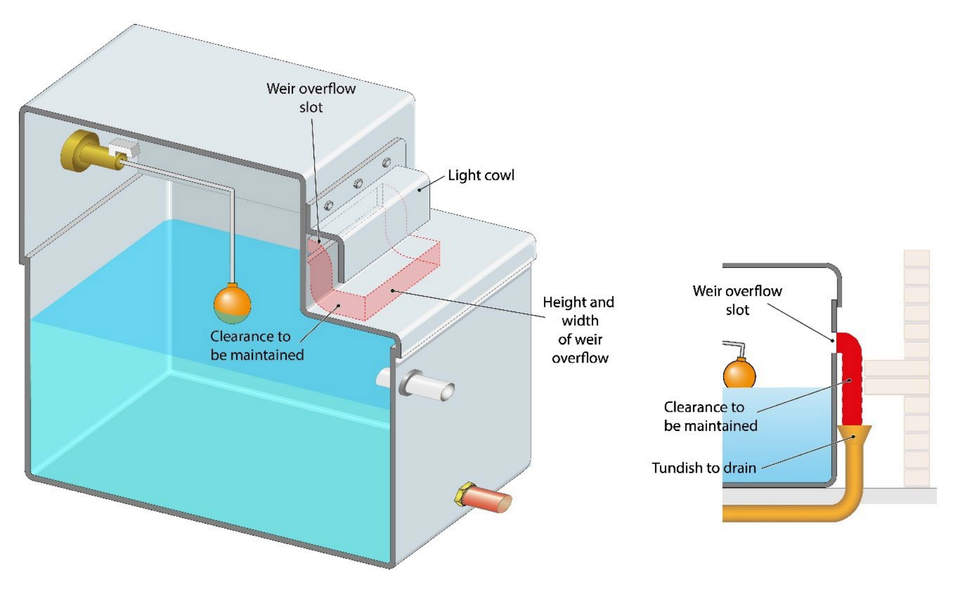

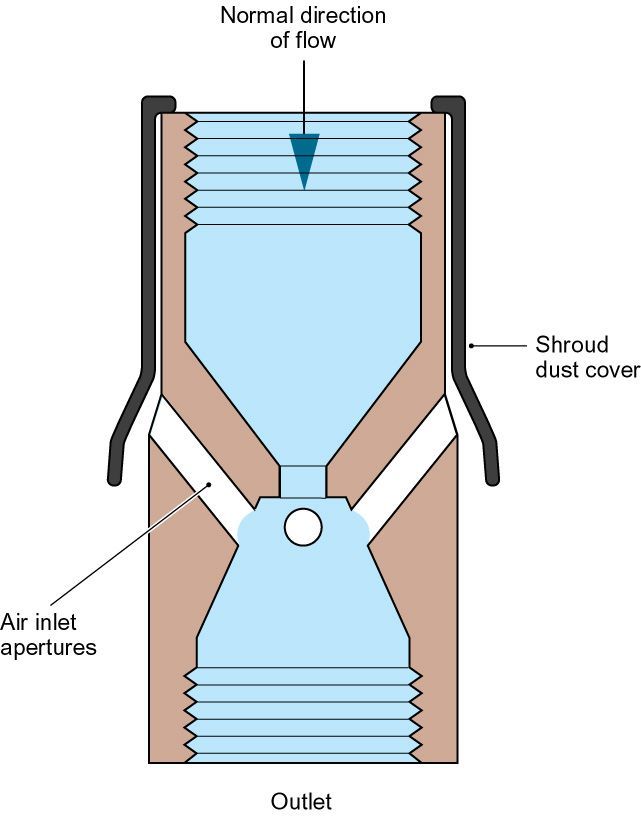

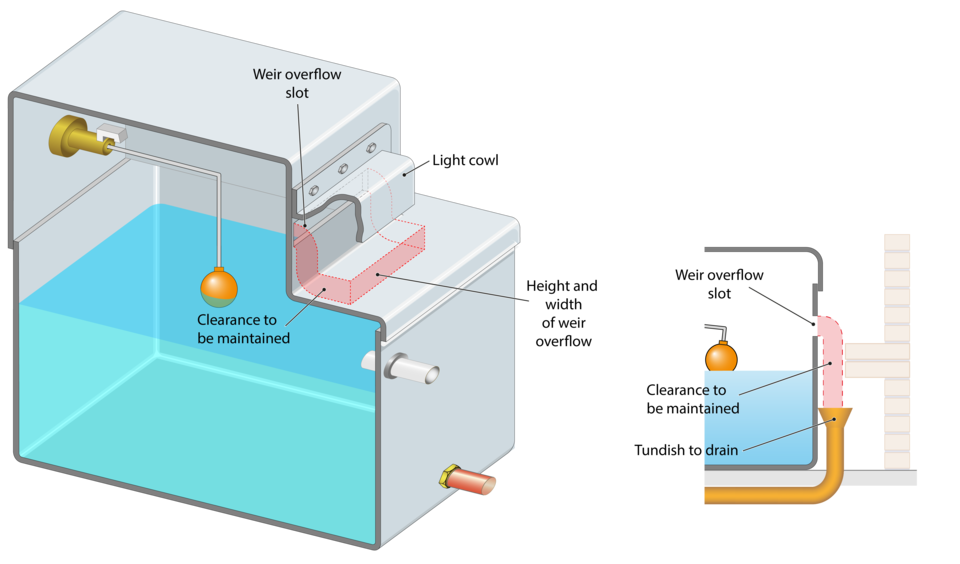

A cold water storage cistern can sometime incorporate a Type AB air gap. Where this is the case it is important to minimise any light penetration through the weir overflow. This is because light is known to promote the growth of algae which could lead to not only taste and odour concerns but also provide nutrients which could support the growth of bacteria. The most common way of addressing this issue is to fit a cowl or shroud that covers the weir slot.

To demonstrate the cowl or shroud arrangement does not impede any discharge it should mirror the overflow weir in size and shape to at least below the lowest point of the weir and any surfaces below or to the side of the cistern as shown below. Information can also be found here

Please note: cold water storage cisterns incorporating a Type AB air gap are sometimes being used as backflow protection arrangements for high risk installation downstream and should not be removed or altered without the agreement of the local water undertaker.

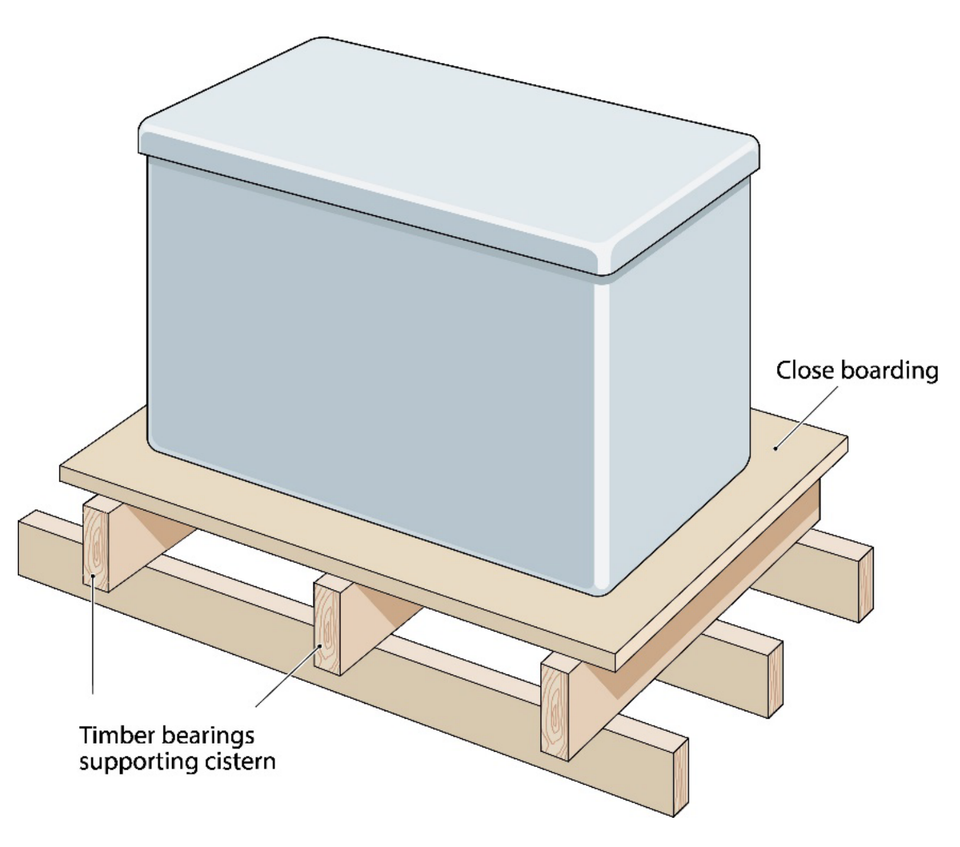

Factors to consider when deciding where and how cold water storage cisterns are installed include but are not limited to:

whether the distributing pipework (system) is pumped or supplied by gravity

the need to allow for ease of access for maintenance • inspection (both internally and externally)

cleaning requirements

environmental factors which might affect water quality such as excessive heat gain or the likelihood of flooding.

Float operated valves and other controls should be readily accessible. There should be sufficient clearance to allow for inspection, cleaning of internal surfaces and maintenance.

Cisterns with a capacity greater than 1,000 litres should be capable of being inspected and cleansed without having to be wholly uncovered.

To avoid distortion cold water storage cisterns should be adequately supported. Advice on how to do this can be found in Part G of the Building Regulations.

Please note: In many cases the local water undertaker will need to be given advanced notice of the proposed installation of any cold water cistern. This is an important simple and essential check to minimise the risk to water supplies.

Due to concerns about water stagnation which might cause the quality of the water to deteriorate the installation of inter-linked storage cisterns should be avoided wherever possible. Where it is unavoidable, the number of inter-linked cisterns should be minimised.

To minimise the risk of stagnation:

The storage volume should be kept to a minimum

Cisterns should be connected in parallel

Any demand should create water flow throughout each cistern

Inlet and outlets should be installed at opposite ends of the cistern

Delayed action float valves should be used

Metering of inlets may assist with balancing of turnover

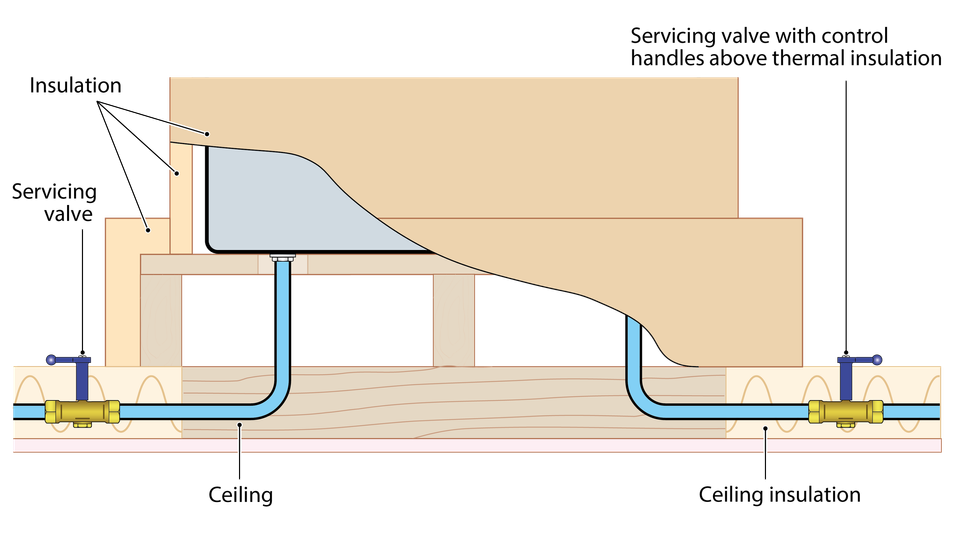

To minimise the risk of damage due to freezing all cold water storage cisterns, including any associated pipework which may be at risk, should be protected. The type and level of protection will be dependent on the environment in which the installation is located.

In premises where there will be water demand or a positive change to the ambient temperature within 12 hours, the insulator calculator can be used to give an indication of insulation requirements. Where this is not likely to be the case the local water undertaker should be consulted as insulation alone may not be suitable.

Undue warming is of concern for two reasons. It can potentially cause a deterioration of water quality and often result in customers leaving taps to run to waste.

Cold water storage cisterns and associated pipework should be sited away from heat sources and insulated.

Systems supplying cold water should be ideally designed to ensure that they distribute water at temperatures no greater than 20°C. This requirement may also apply under other legislation and code of practices, such as those relating to legionella control.

Good system design, commissioning and maintenance will help to reduce and address the risk of contamination resulting from microbial growth and limit waste due to taps left to run.

Storage and distribution temperature requirement for domestic hot water systems are set out in other legislation, codes of practice and British Standards.

For further information please refer to Building Regulations, BS EN 806, BS 8558, HSC L8 and CIBSE Commissioning Code M.

The risk is dependent upon the fluid, the dose used and concentration within the system. The volume of fluids and operating pressures will also be considered when assessing the suitability of the backflow protection device or arrangement to be installed.

Please note the final decision rests with the local water undertaker.

Yes, appropriate separation is required. Minimising the risk of contaminated fluids coming into contact with water to be used for domestic purposes (drinking, bathing, washing, cooking etc) is a key objective of the water fittings regulations/byelaws.

Mindful of the need to ensure sufficient safeguards are in place to address the possibility of drinking water supplies coming into contact with fluids which are not considered to be wholesome, in determining whether systems making use of heat recovery or exchange are compliant with regulation 4(1) the following factors will be taken into consideration. Please note decisions will be taken on a case by case basis.

The actual fluid categories of the fluids within the system.

How readily identifiable any potential integrity failure of the system would be.

Whether the system design meets the requirements for single or double wall separation specified in BS EN 1717.

Where a closed circuit (heating system etc) has been categorised by the water undertaker as a fluid category 3 risk, the installation of a compliant double check valve on the fill point connection to the supply/distribution pipe may be considered as acceptable backflow protection.

Where a fill point connection incorporates a “flexible connection”, when not in use it is good practice for the hose to be completely disconnected and removed. However, a partial disconnection, that is to say only detaching one end of the hose, may be acceptable providing the disconnection is made between the hose and the backflow prevention device on the supply/distribution pipe.

Please note: if the water undertaker has concerns about the likelihood of contamination, or the suitability of a double check valve - for example due either to age, operating temperature or pressure fluctuations – under schedule 2 paragraph 15(4) they can require the installation of additional backflow protection. Further information about backflow protection can be found in the Guidance section on the Water Reg UK website.

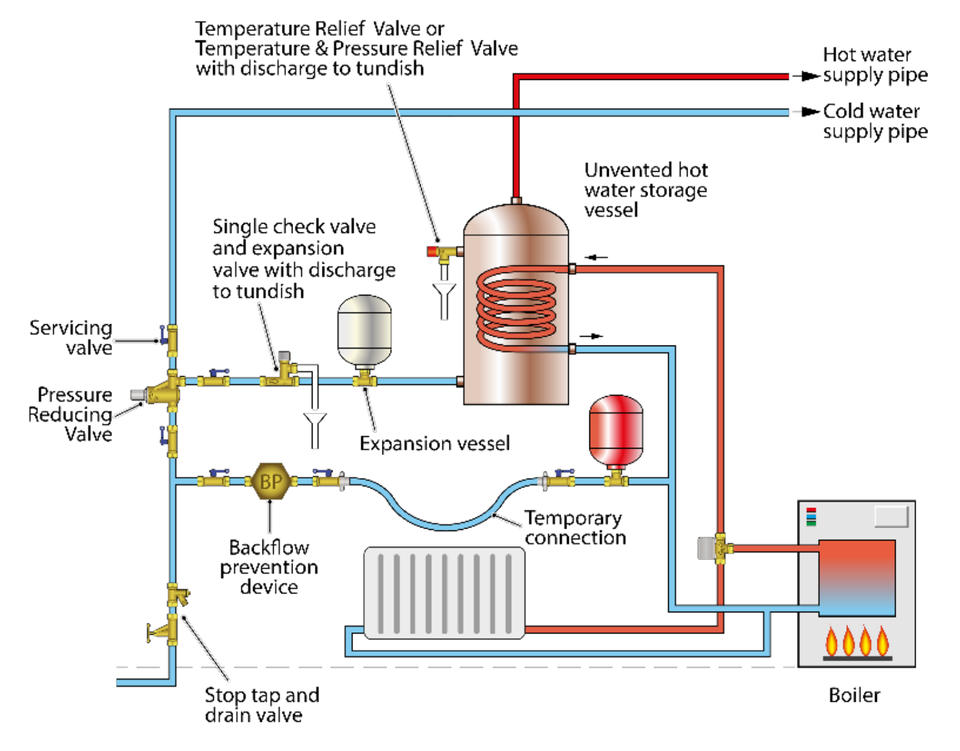

Acceptable safety devices include:

Temperature relief valves

Temperature control arrangements such as non-self-resetting energy cut outs and cylinder thermostats (interlocked to prevent flow from the primary circuit).

Combined temperature and pressure relief valves

Pressure reducing valves

Expansion vessels installed in combination with expansion relief valves. For further information, including advice about safety device arrangements for different methods of heating, please refer to the relevant version of the Building Regulations.

All safety devices must comply with the requirements of regulation 4(1). Examples of appropriate British Standards are given in the guidance to part G of the Building Regulations.

All water fittings must be suitable for the circumstances in which they are used. In addition to the normal system operating temperatures and pressures consideration should be given to the suitability of components for use at elevated temperatures likely to be encountered under fault conditions.

The safety arrangements installed on a water heater used to heat water for domestic applications should prevent the temperature exceeding 100o C.

The suitability of safety arrangements for other applications, for example industrial processes will be assessed on a case by case basis.

Where the source of heat energy cannot be relied upon in all circumstances to achieve the required minimum temperature to address concerns about microbiological growth an additional heat source should be available.

Any discharge from a hot water system safety device should be safe and conspicuous. Where a discharge is made via a tundish it should conform to the applicable British Standard or equivalent. For further information please refer to the relevant version of the Building Regulations.

Advice regarding the sizing of hot water system vent pipes can be found in the guidance to part G of the Building Regulations, BS EN 806 and BS 8558.

All hot water systems must be capable of accommodating expansion. There are various ways to do this including:

(a) Secondary hot water systems only

The water fittings regulations/byelaws permit accommodation within the secondary hot water system, of thermal expansion from unvented water heaters (with the exception of instantaneous water heaters with a capacity less than 15 litres).

This is however only allowed if:

The expanded water does not increase the temperature of the water in the supply pipe to in excess of 25°C in England and Wales 20°C in Scotland and Northern Ireland. As this may result in waste or impact on wholesomeness.

Both the expanded water plus any displacement can be accommodated within the supply pipe. It is not permissible for water displaced as a result of accommodating expansion to backflow into the pipework owned by the local water undertaker.

(b) Primary feed and expansion cisterns

To prevent waste the preset water level for expansion cisterns or combined feed and expansion cisterns should accommodate at least 4% of the total volume in the primary (heating) system circuit before discharging through the overflow or warning pipe.

(c) Expansion vessels

To address contamination concerns associated with stagnation and particulate accumulation it is recommended expansion vessels be installed so as to avoid localised low turnover (stagnation).

Specifically, they be installed securely in the vertical so that the water fitting is:

bottom fed and upright

the connecting pipework to the fitting

rises continuously

is kept to a minimum

sized correctly for the system

designed to ensure an adequate turnover of water within the expansion vessel.

Please note: Where an expansion vessel is used an expansion valve which operates at an appropriate operating pressure must be fitted to ensure water discharges safely and conspicuously in the event of a malfunction. To prevent waste the expansion valve must automatically close after a discharge.

No intervening valves should be installed between the expansion vessel, expansion valve and hot water heater/storage.

Protecting public health by minimising the risk of contaminated fluids coming into contact with water to be used for domestic purposes is a key objective of the water fittings regulations/byelaws. In keeping with this principle, where there is considered to be a contamination risk this is either mitigated by avoidance or safeguards such as installing backflow protection.

Depending upon their design and fluids involved, heating and cooling systems which make use of heat recovery or exchange, including but not limited to those listed below, pose different potential contamination risks.

Heat exchangers linking primary and secondary systems

Ground source and air source heat pumps

Chillers

Calorifiers

Heat recovery products utilising the heat energy in wastewater

In enforcing the regulations/byelaws water undertakers take a risk based and proportionate approach. Enforcement policies cite the need to be transparent, consistent, targeted and accountable.

Mindful of the need to ensure sufficient safeguards are in place to address the possibility of drinking water supplies coming into contact with fluids which are not considered to be wholesome, in determining whether water fittings/systems making use of heat recovery or exchange are compliant with regulation 4(1) the following factors will be taken into consideration. Please note decisions will be taken on a case by case basis.

The actual fluid categories of the fluids within the system.

How readily identifiable any potential integrity failure of the water fitting/system would be.

Whether the fitting design meets the requirements for single or double wall separation specified in BS EN 1717.

Please note: pipework supplying water for domestic use should be external to and separate from wastewater pipework. It should not be sealed within a fitting which conveys wastewater unless the local water undertaker has been notified and given consent.

The purpose of the water fittings regulations/byelaws is to prevent contamination, waste, misuse, undue consumption and erroneous measurement. There are a number of regulators responsible for enforcement of safety requirements including the Health and Safety Executive, Trading Standards and local authorities. Satisfying the water fittings regulations/byelaws does not guarantee compliance with the regulations these bodies enforce.

The method of support and spacing between supports will be dependent on the type of water fitting and material it is constructed from.

In the case of pipework allowance should be made to accommodate likely movement for example thermal expansion and contraction.

Useful sources of information include BS EN 806:4, and BS 8558.

Water fittings considered to be concealed include those:

Buried in the ground

Installed below or embedded in floors

Installed in or behind wall finishes

Water fittings considered not to be concealed include those:

Installed below ground but not buried, such as in a chamber or basement room

Installed below floors or in walls which can be readily accessed

Joints on concealed pipework are likely to lose their integrity over time and therefore should only be considered where unavoidable.

To prevent waste there needs to be provision to access any joints or water fittings which require maintenance, such as backflow prevention devices, valves which control the flow and any other operational fitting.

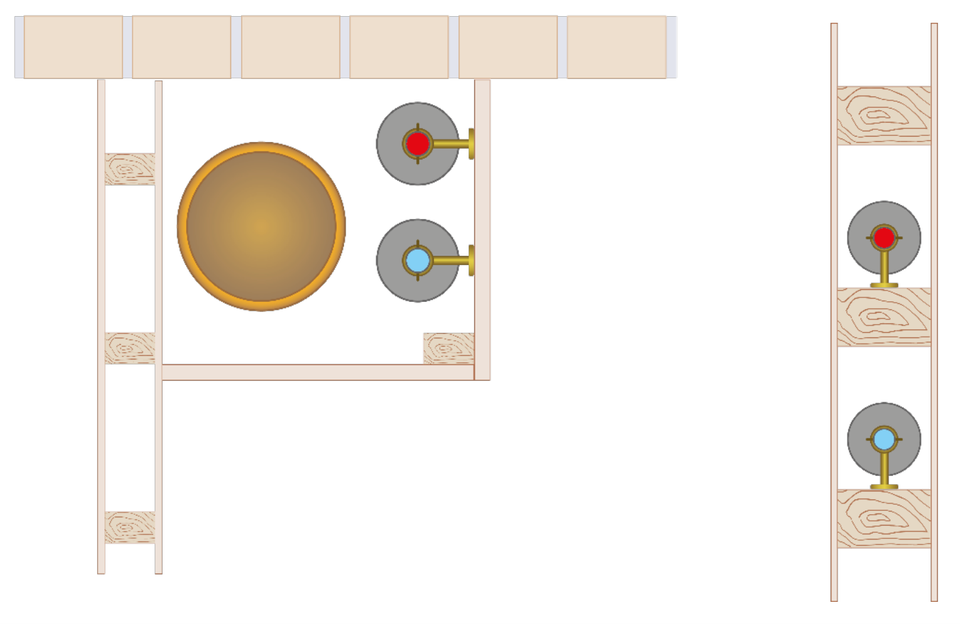

All domestic hot and cold water system pipework concealed within walls should:

Be installed with a minimum number of joints. This is because joints are prone to a loss of integrity over time and therefore should only be considered where unavoidable.

Be installed in a chase/duct or void. Wrapping pipework in insulation is not an acceptable method of ducting or passing through a chimney is not an acceptable method of ducting.

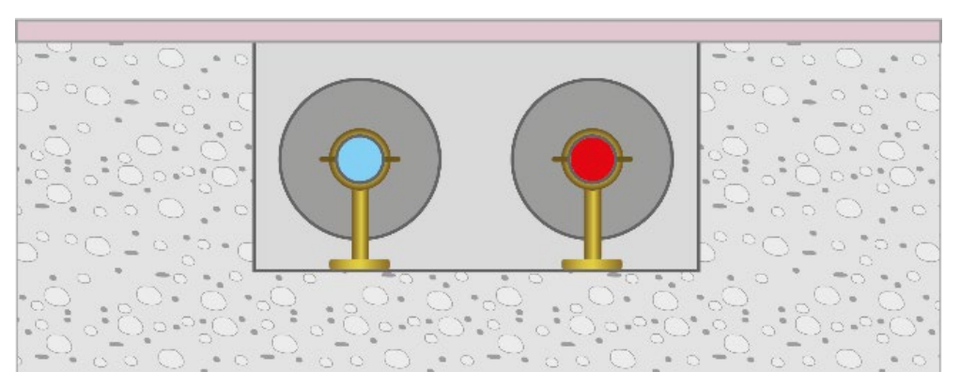

With the agreement of the local water undertaker pipework may be installed alongside other services in a shared duct. An example of what may be considered as acceptable is shown below.

Be appropriately clipped to avoid water hammer and other stresses which would affect the integrity of the installation.

Be insulated with a suitable gap maintained between the cold water, hot water and any other heat source to prevent heat transfer or loss.

Not be embedded or come into contact with other materials such as plaster or cement.

Be accessible to enable inspection and replacement. Further information about accessibility can be found in BS 8558.

Below are images illustrating domestic hot and cold water systems concealed in a wall and a soil pipe duct.

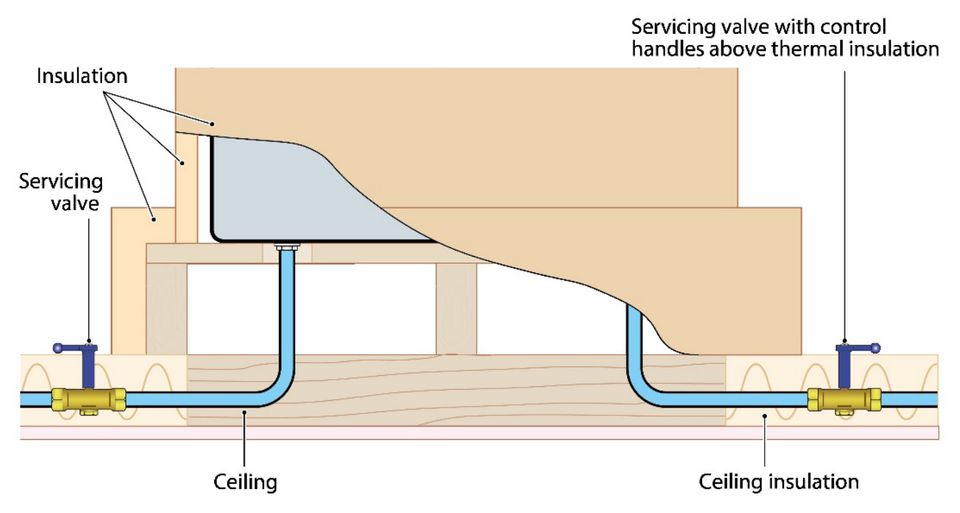

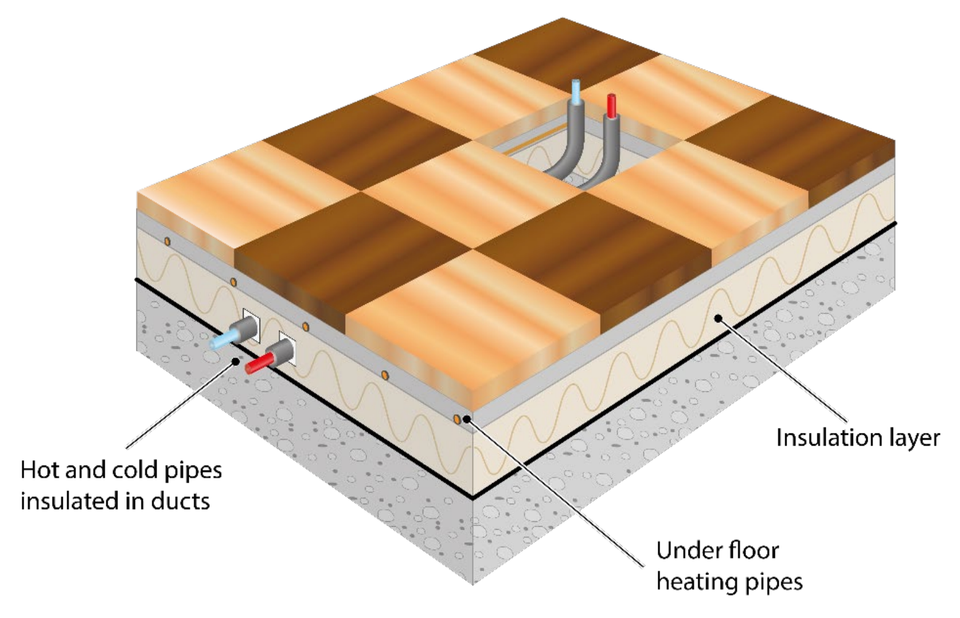

All domestic hot and cold water system pipework concealed within floors should:

Be installed with a minimum number of joints. This is because joints are prone to a loss of integrity over time and therefore should only be considered where unavoidable.

Be installed in a chase/duct or void. Wrapping pipework in insulation is not an acceptable method of ducting.

Be appropriately clipped to avoid water hammer and other stresses which would affect the integrity of the installation.

Be insulated with a suitable gap maintained between the cold water, hot water and any other heat source to prevent heat transfer or loss.

Not embedded or come into contact with other materials such as backfill, screed or cement.

Be accessible to enable inspection and replacement. Further information about accessibility can be found in BS 8558.

Underfloor heating systems should be installed in a manner considered to be acceptable to building control and the local water undertaker.

If domestic supplies are to be installed in close proximity to underfloor heating, they should:

Be installed as a single run of pipework without any inaccessible joints below the underfloor heating insulation.

To prevent heat transfer or loss any supply pipework should be laid with a suitable gap maintained between the hot and cold systems and both wrapped in insulation.

Firstly, the pipe and fittings, including method of connection, should be suitable for below ground use and the environment in which they are to be installed. Joints should be kept to a minimum. Water fittings which are susceptible to permeation by hydrocarbons should not be laid in ground near installation storing or ground contaminated with petrol or oil unless protected.

Pipework should be laid at a depth of not less than 750 mm (to limit the effect of freezing and mechanical damage) and no greater than 1350 mm deep. They should be embedded in nonabrasive materials. Where this cannot be achieved in all circumstances the consent of the local water undertakers must be obtained via notification.

Where the local water undertaker consents to pipework being laid at less than 750 mm it should be installed as deep as possible below ground level and protected against warming, freezing and mechanical damage (for example due to ground movement).

Pipework should not be installed above ground level is not permitted without the agreement of the local water undertaker.

Examples of how to avoid below ground obstructions are given below. Please note the local water undertaker should be consulted before laying pipework over an obstruction.

Pipework should never be installed in a contaminated environment such as a sewer or cesspool.

Non-metallic (plastic) plumbing fittings are at risk of permeation by diesel or heating fuel, pesticides, insecticides and similar organic substances or fluids, so should never be installed where they could come into direct contact, including contact with soil contaminated with them.

Where this is unavoidable contact the local water undertaker for advice.

Non-metallic water fittings which are susceptible to permeation should not be installed in close proximity to other services for example gas pipelines, or in ground contaminated with hydrocarbons or other contaminants of concern.

For further advice contact the local water undertaker.

The recommended distances between utilities can be found in the latest National Joint Utilities Group (NJUG) guidelines. Where these dimensions and depths cannot be achieved protective measures will be required.

If the installation of the pipework is notifiable, under regulation 5 of the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland, installation advice should be provided as part of the notification process.

If it is not notifiable there remains a legal obligation for the premises owner or occupier to ensure the plumbing work is fully compliant with the water fittings regulations, byelaws in Scotland.

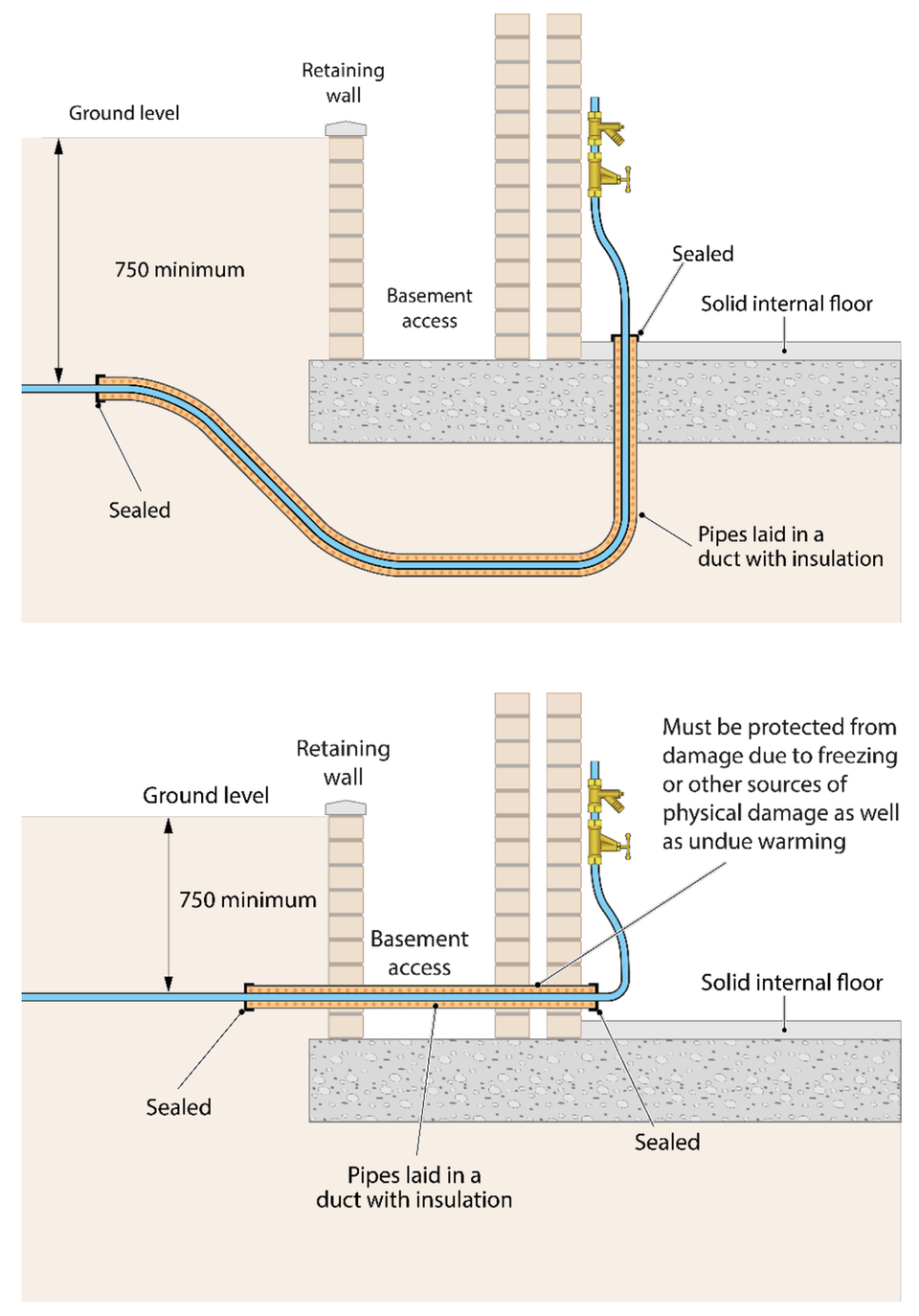

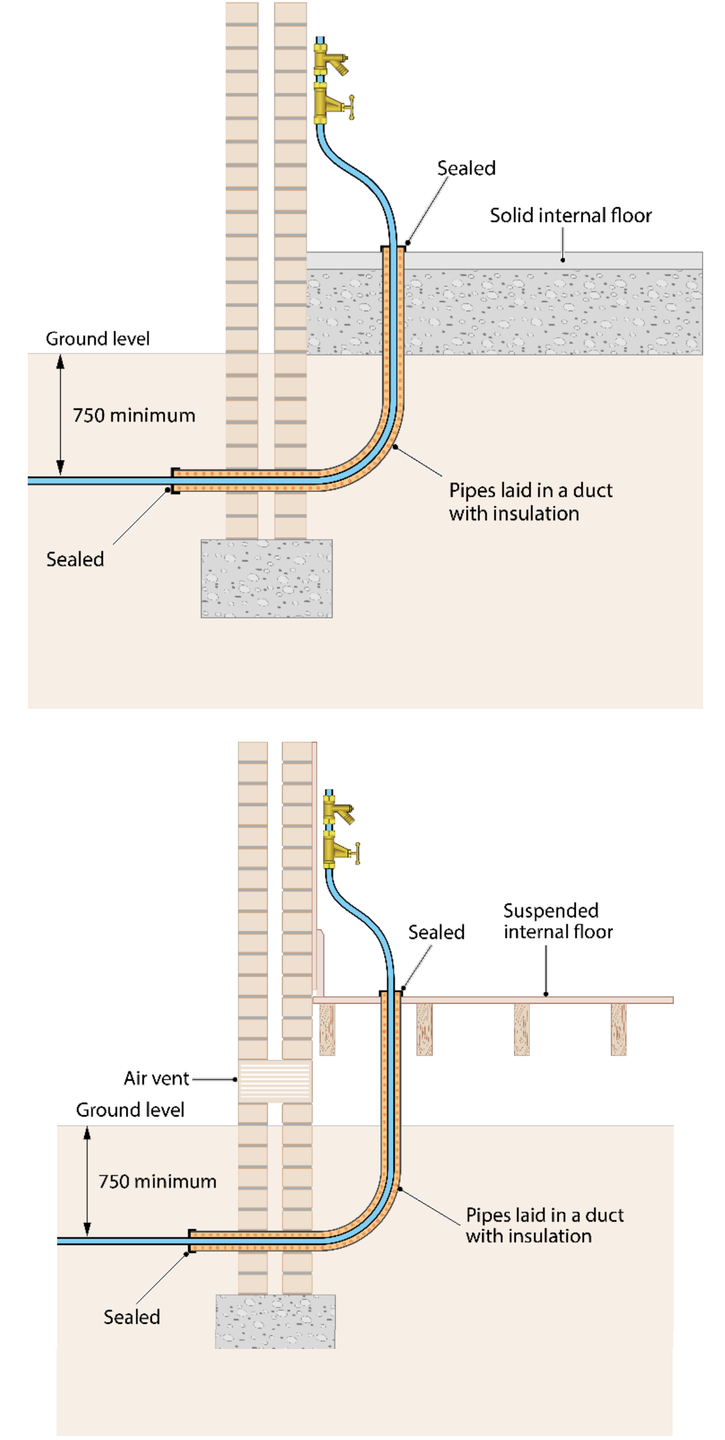

The supply pipe to a building should enter at a depth of 750 mm.

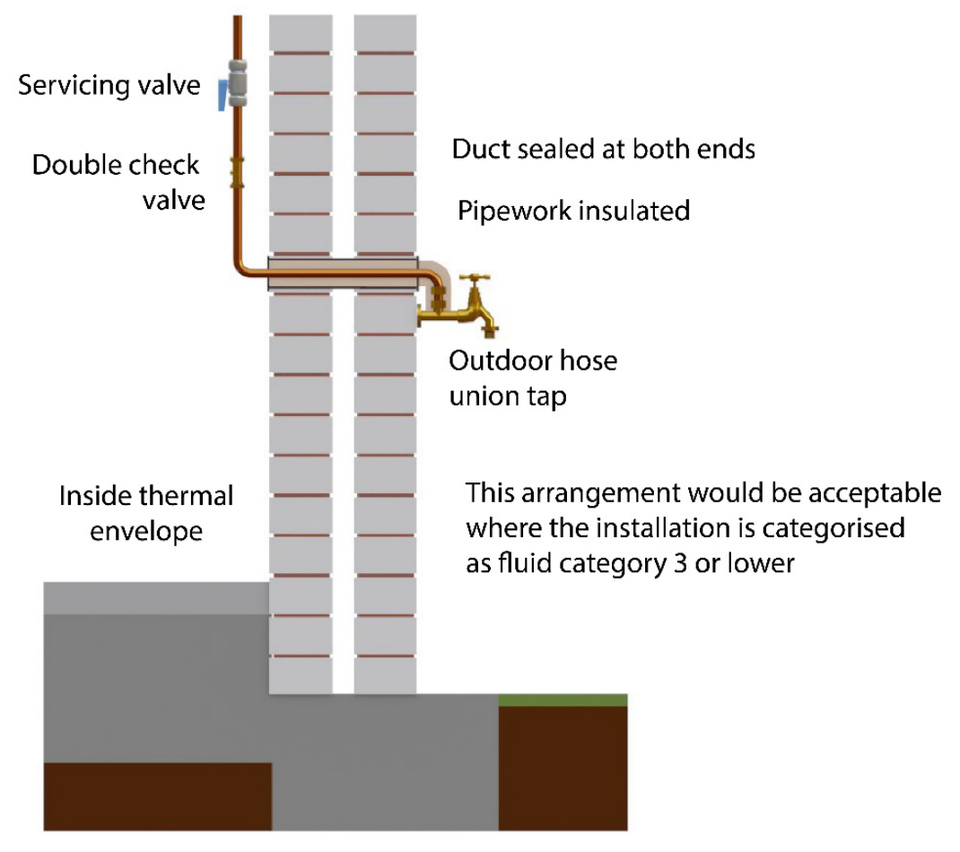

Pipework passing through walls and laid at depths of less than 750 mm, including any inside the building should be ducted. This is to prevent damage and facilitate ease of replacement, the internal surface of the ducting should be smooth bore i.e. any ridging to be external only.

The pipework should be sealed using a method acceptable to the local water undertaker. This is to prevent ingress of gases and vermin. It should also be adequately insulated. Where pipework is installed below a suspended floor if there is an air vent the pipework should be ducted and insulated to the finished floor level.

In premises where there will be no water demand or a positive change to the ambient temperature after 12 hours, the insulator calculator can be used to give an indication of insulation requirements. Where this is not likely to be the case the local water undertaker should be consulted as insulation alone may not be suitable. Example of pipework entering a building at and below street level are given below.

In addition to the requirements already listed, above ground plumbing must be protected against environmental conditions, accidental, mechanical and animal damage.

A regular inspection should be undertaken of pipework and water fittings to identify leaks or other issues. This will help to reduce waste, prevent contamination and save cost.

The type and level of frost protection required will depend upon the environment in which a water fitting is installed, with insulation and trace heating commonly used.

Any water fitting installed outside the thermal envelope or at depths of less than 750 mm should be protected against damage caused by freezing.

Any not used during cold weather, such as seasonal irrigation systems should be isolated and drained down. Similarly, if a premises is to be left unoccupied and unheated during cold weather, for example a holiday home or caravan, the water supply should be turned off and plumbing system drained.

When installed in accordance with the manufacturer’s instructions insulation may delay but not prevent freezing.

Providing within 12 hours the plumbing system is used (there is demand flow) or there is an increase in the ambient temperature, the insulator calculator can be used to give an indication of insulation requirements for installations exposed to low temperatures. Where this is not likely to be the case the local water undertaker should be consulted as insulation alone may not be suitable.

Information on installing underground water storage which is

Supplied directly from mains

Installed below ground level, wholly or partially outside the thermal envelope

can be found in the Underground Storage Guidance booklet

The image below is to be used in conjunction with this document.

Information on installing wastewater and chemical emptying points can be found in the the Camping sites, caravan holiday parks and residential park home estates booklet.

The image below is to be used in conjunction with this document.

If water is supplied for drinking, cooking, bathing or washing (domestic use) a drinking water tap must be installed. Where possible this should be supplied direct from mains i.e. not via any water fitting which stores, treats or filters the water.

It is recommended where possible drinking water taps be connected directly to the incoming mains water supply. Where this is not feasible, they can be fed from a storage cistern or pumped, but wholesomeness must be maintained, meaning the water fittings used must not adversely affect water quality.

Any tap supplying water which is not wholesome must be labelled in accordance with BS 1710. In non-household premises it is recommended all taps are labelled to help users to distinguish between sources of drinking and non-drinking water.

Yes, as long as it’s of an appropriate quality and standard. Please note if the softened or conditioned water is to be used for drinking, cooking, bathing or washing (domestic purposes) then it must remain wholesome i.e. satisfy water quality requirements.

A self-closing tap is one which turns itself off automatically after a set time or volume of water has been discharged, for example non-concussive and infrared taps often used to save water or in areas where taps are prone to being left open.

Wholesomeness is defined in water quality regulations (England & Wales, Scotland and Northern Ireland). To be considered as wholesome water must:

Meet all the prescribed standards set out in the relevant version of the water quality regulations.

Be aesthetically acceptable to customers in terms of appearance, taste and odour.

Not contain anything, either alone or in combination, which may be harmful to health.

If the installation of a multifunction tap is notifiable, under regulation 5 of the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland, installation advice should be provided as part of the notification process.

If the installation is not notifiable there remains a legal obligation for the premises owner or occupier to ensure the plumbing work is fully compliant with the water fittings regulations, byelaws in Scotland. To assist installers water undertakers and Water Regs UK publish installation guidance on a range of topics including multifunction taps.

If there are any further questions, please contact the local water undertaker for advice.

Overtime minute traces of copper (which is an essential element that naturally occurs in water) become trapped within plastic materials used to manufacture a kettle. When these traces then comes into contact with oxygen inside the kettle they undergoes a process called oxidation, turning them black.

It can be washed out using a weak acid solution, such as a kettle descaler, readily available in most supermarkets and online retailers. These are not harmful when used in accordance with the manufacturer’s instructions.

There are normally two reasons why water may appear cloudy, both are usually harmless.

The most common reason is minute bubbles of air trapped in the water. These air bubbles are so small that they are not readily visible to the naked eye and customers often describe this as their water having a ‘white cloudy’, 'milky' or ‘chalky’ appearance.

Air bubbles in the water may be caused by for a number of reasons:

A loose or worn tap washer, this is usually accompanied by a distinctive ‘singing’ sound from the tap at certain flow rates.

A sudden reduction in pressure (because of opening the tap) which can release air dissolved in the water, in the same way as dissolved carbon dioxide is released when a bottle or can of fizzy drink is opened. This can be confirmed by filling a clear glass with water and checking to see if the cloudiness clears from the bottom to the top of the glass.

Maintenance work on your plumbing installation may cause air to become trapped within the system, especially if your water supply was turned off temporarily during the work.

If your hot water pipes run too close to your cold water pipes.

Another cause of white/cloudy water can be small particles in the water. These particles may have become dislodged from pipework or other water fittings within the property, becoming suspended in the water giving it a white cloudy/opaque appearance.When a glass is filled any such particles would slowly sink, leaving chalk like deposits at the bottom of the glass.

In both cases, leaving your taps running at a gentle steady flow for a short period should resolve these issues.

When iron deposits become re-suspended, they can react with the oxygen in the water which can result in it becoming yellow in appearance, this is generally harmless. This discoloration can be caused by a disturbance in the main, such as a burst, or a cast iron pipe (typically used in the 1950’s and 1960’s) coming to the end of its life. In the case of the latter the yellow discoloration may also be accompanied by brown or black flecked particles. This may be as a result of a change in flow pressure (such as following a burst pipe or excessive supply demand) disturbing harmless deposits within the pipework.

If the water has a bright or fluorescent yellow colour, contact your water undertaker.

Clean water will naturally have a blue hue to it. Water which has a definite blue or turquoise colour as opposed to hint, is often due to new copper pipe work or the use of poor quality brass fittings. To help prevent this from happening new pipe work needs to be thoroughly flushed, which may need to be repeated over a period of weeks until the pipework stabilises, and make sure brass fittings are manufactured from appropriate materials.

Another source of intense blue water may be water siphoned back via inlet valves supplying toilet cisterns. Where the inlet to toilet cisterns is installed incorrectly water coloured by a toilet block (the colour of the water will depend on the colour of the toilet block used, if this is the issue) can be back siphoned into the plumbing system.

If you suspect you have elevated level of copper or water back siphoned from a toilet block, please contact your water undertaker for advice.

If your water has a rancid or rotten odour or taste, then it is important to determine the source of the supply. If it is fed from a storage cistern this should be inspected for any signs of any animals or birds having gained access.

Where evidence of animal or bird activity (access into the cistern) is found the storage cistern plus any associated pipework arrangements should be drained, cleaned and thoroughly disinfected.

If the supply is direct from the main, then contact the water undertaker immediately. They will be able to provide further help and advice.

Sometimes a sewage or stagnant type smell can emanate from a sink or plug hole, especially if the water draining away is warm. This indicates a possible blockage or build-up of waste materials, making the drinking water appear as if it has an unpleasant smell. Filling a glass with water, taking it into a different room (away from the kitchen sink) and then smelling it, may help to determine whether the odour is genuinely from the water or not.

If the water still smells, please contact the water undertaker immediately.

Chlorine in drinking water is not harmful. It is added to drinking water as the final stage of treatment to protect public health. Water undertakers monitor chlorine concentrations closely to keep the levels as low as possible whilst keeping water supplies safe. Concentrations can vary throughout the day and year. They may be higher if you live close to a water treatment works.

Some people are sensitive to the taste and smell of chlorine. The taste of chlorine can be reduced by allowing it to stand in a closed container in a fridge until needed. If this does not work, try boiling the water for about five minutes before storing it. This should remove most of the chlorine. If not drunk within 24 hours, it should be used for purposes.

Home treatment devices like a water filter, are generally not necessary but some customers like to use them. These typically make use of activated carbon to absorb chlorine and other substances which can influence the taste of the water. Please note water treatment devices must be of an appropriate quality and standard. If not properly maintained, they may cause water quality problems.

A chlorine or metallic taste, especially in hot drinks, may not be due to the presence of chlorine. Instead, it is more likely to be associated with non-metallic plumbing materials, such as rubber washers, or hoses if you have appliances (such as vending machines, dishwashers, washing machines and garden hoses) plumbed in close to taps used for drinking water. The plasticiser in these products combines with the residual chlorine in drinking water, and when heated forms antiseptic/TCP tasting compounds when are most noticable in tea and coffee.

In the case of appliances this can be remedied by either changing the hoses for ones which are compliant with BS 6920 or installing a double check valve on the supply to the appliance. Garden hoses should always be disconnected from the hose union tap when not in use and should ideally be fitted with a trigger release gun for when in use.

There are a number of organisms which can cause a musty/earthy taste or smell in water that can grow inside taps. These are generally harmless.

If you notice this smell or taste, try using a mild household disinfectant to wash outside and inside your tap then running it a little before you use it again to rinse out the disinfectant.

If you have done this but are still concerned contact your water undertaker.

If there is a taste or odour of petrol or diesel to the water from your kitchen tap, please contact your water undertaker straight away and do not drink the water or use it for cooking purposes until you have sought their advice.

The most common cause of this issue are leaks or the spillage of hydrocarbons (the chemical compounds found within fuel and similar products).The water undertaker will want to know whether you have had any work done at the property (for example on the heating system), if you have any oil storage tanks or have recently had any oil spills at the premises (for example a car or motorbike leaking oil).

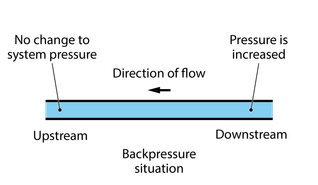

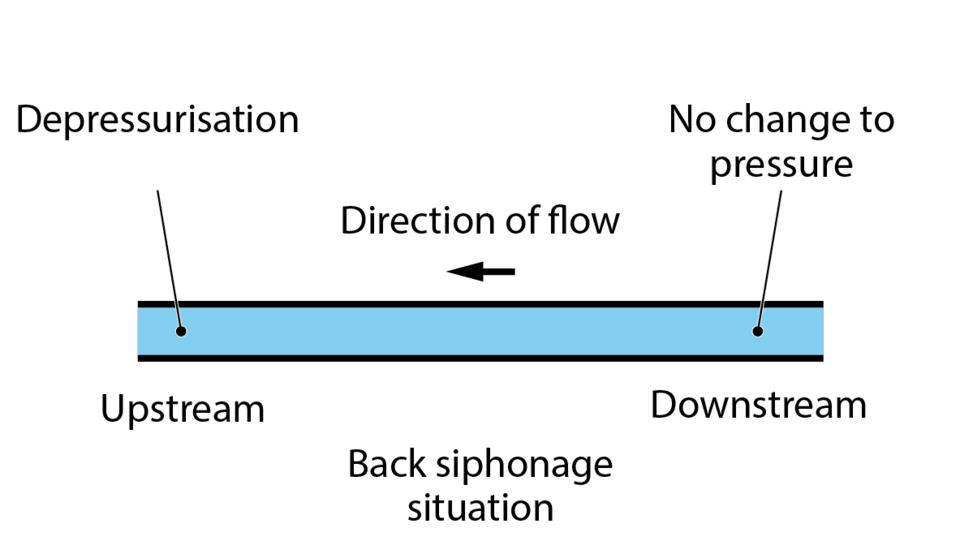

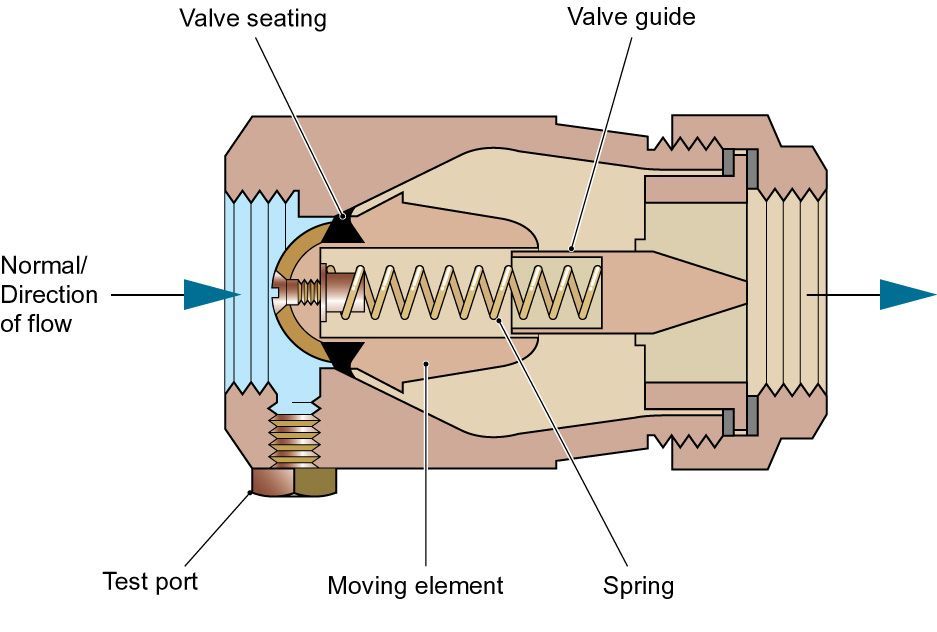

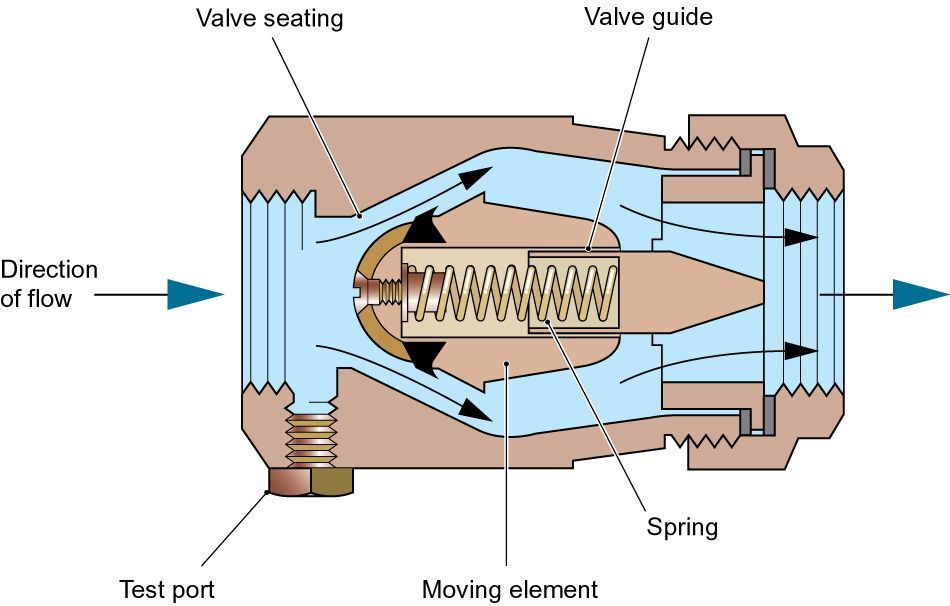

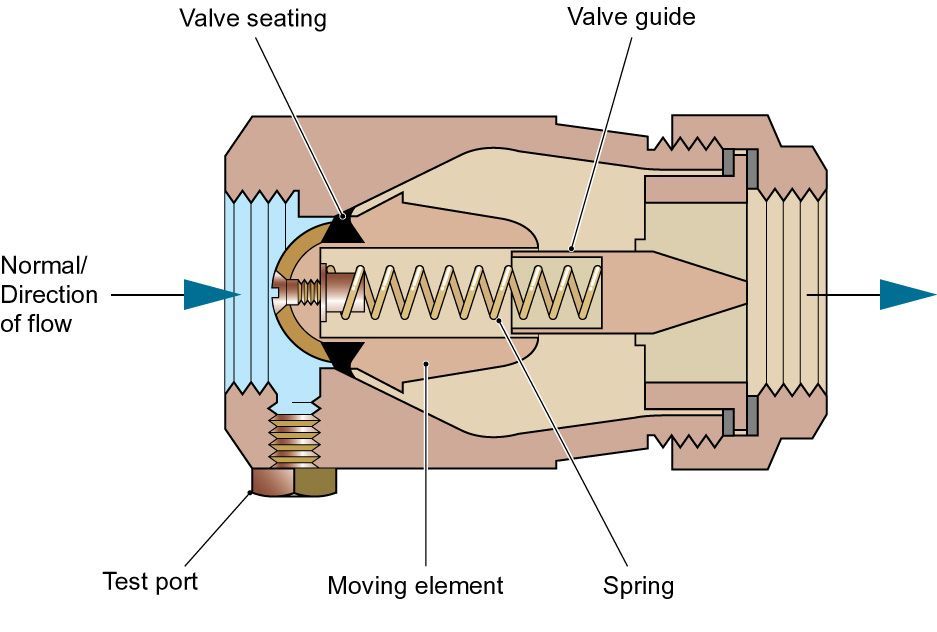

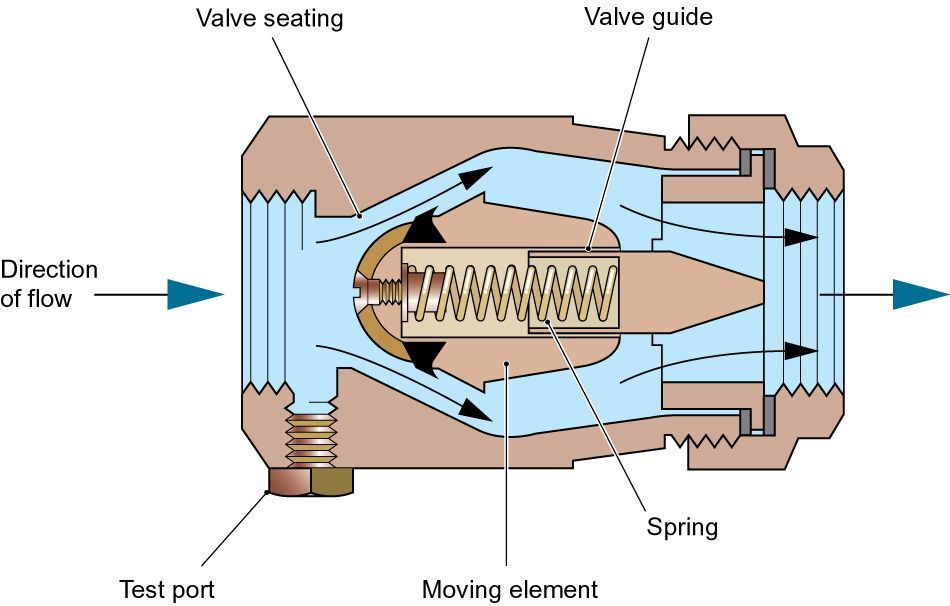

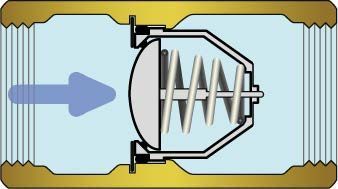

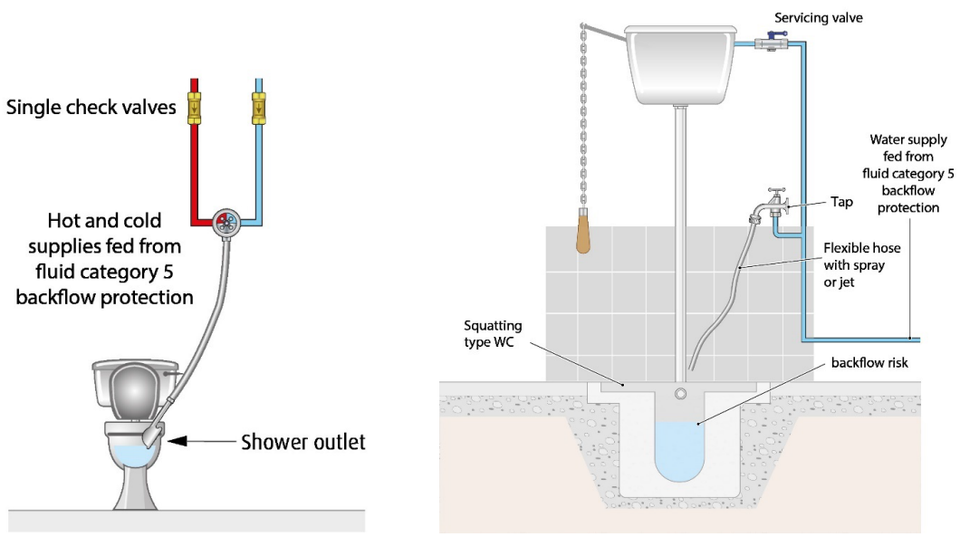

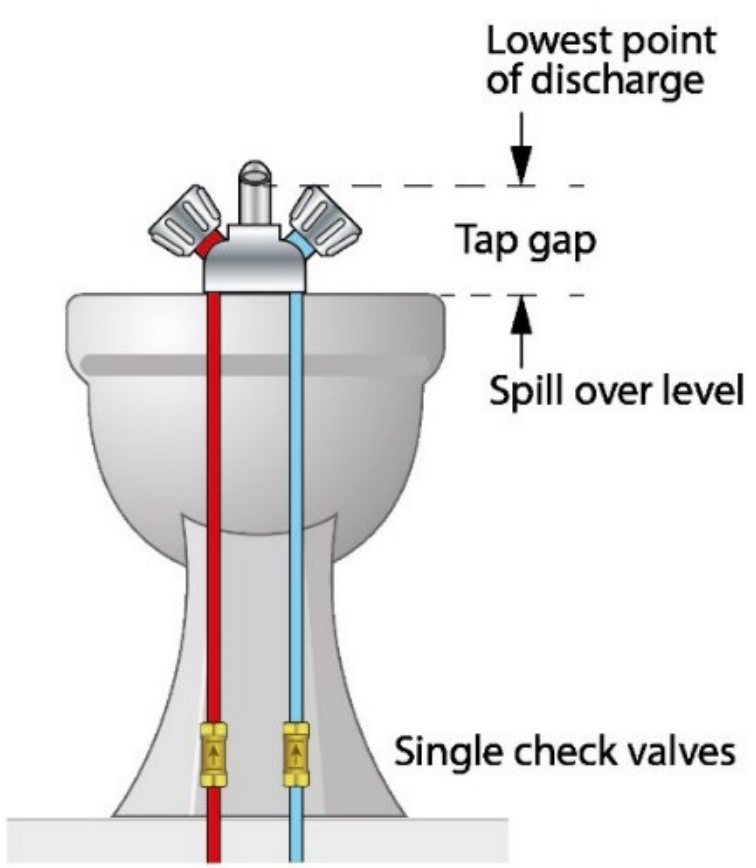

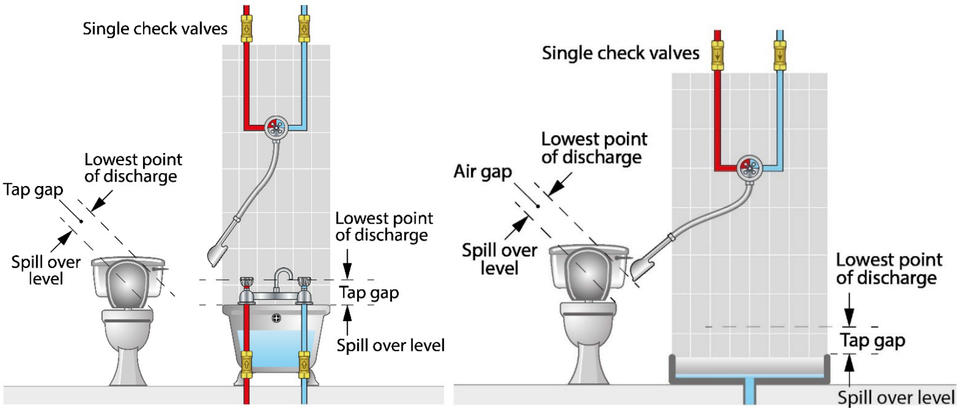

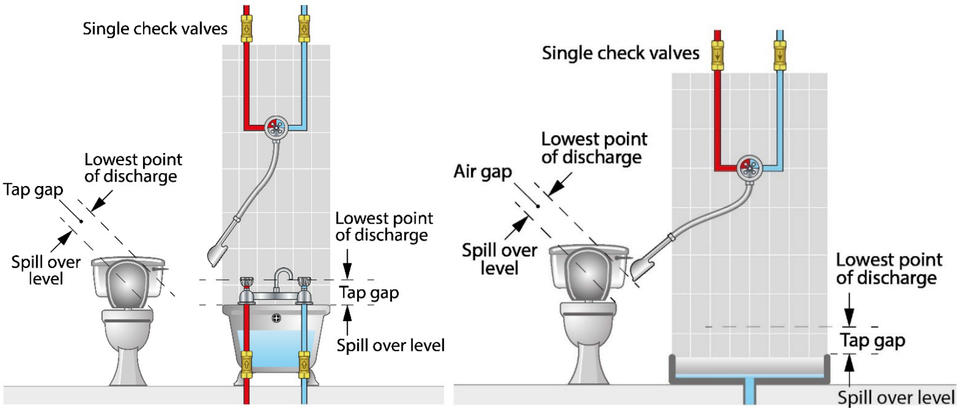

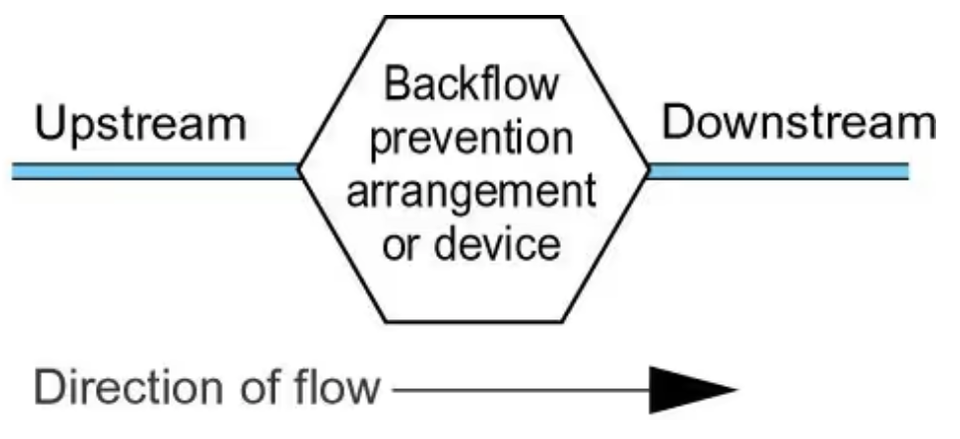

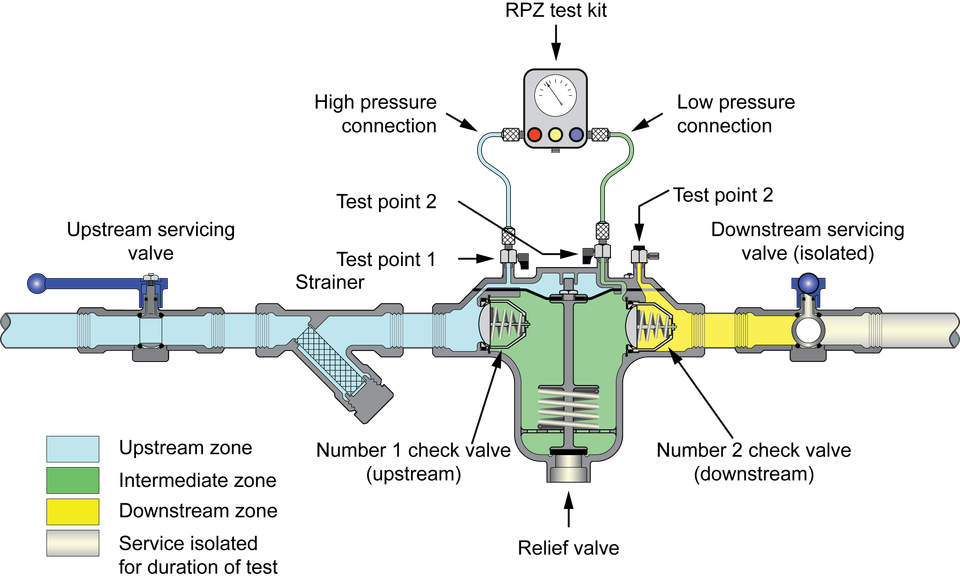

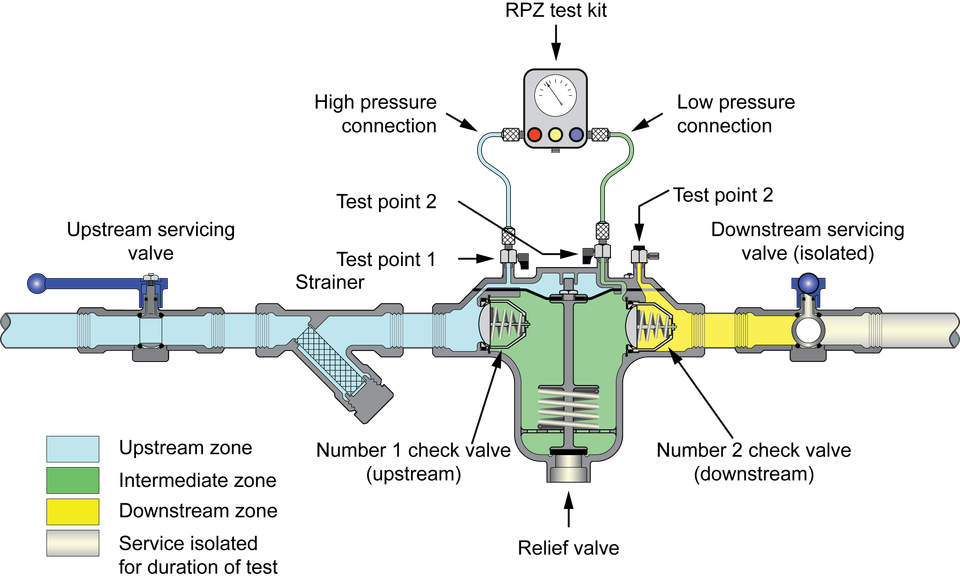

Backflow occurs when fluid flows in the opposite to the intended or normal direction of flow. There are two types of backflow, back pressure and back siphonage.

Backpressure: occurs when the pressure downstream increases above that of the supply pressure, in effect pushing fluids backwards against the intended or normal direction of flow.

Back siphonage: occurs when the supply pressure drops below that of the system it is supplying creating a depressurisation or vacuum which pulls fluids backwards against the intended or normal direction of flow.

The type of backflow risk is dependent upon a number of factors. Good design and the installation of suitable backflow prevention arrangements are key to avoiding backflow, which is why notification is so important.

As the circumstances which could lead to backflow are a common occurrence across the UK, contamination of public water supplies by backflow of fluids from customers premises is not theoretical. It is an ever present threat to water quality and public health.

As there have been a number of serious contamination events across the UK water undertakers take their role in preventing such incidents very seriously. Where infringements are suspected or identified they will act, not only to protect water quality and public health, but also to support owners and occupiers of premises to meet their legal obligations.

Where contamination incidents occur, it is likely that enforcement action, including criminal proceedings, will be taken against those who fail to meet their legal obligations.

Water undertakers are legally required to ensure the drinking water they supply is wholesome. Contamination occurs when there is a change in water quality irrespective of whether or not it is harmful to health

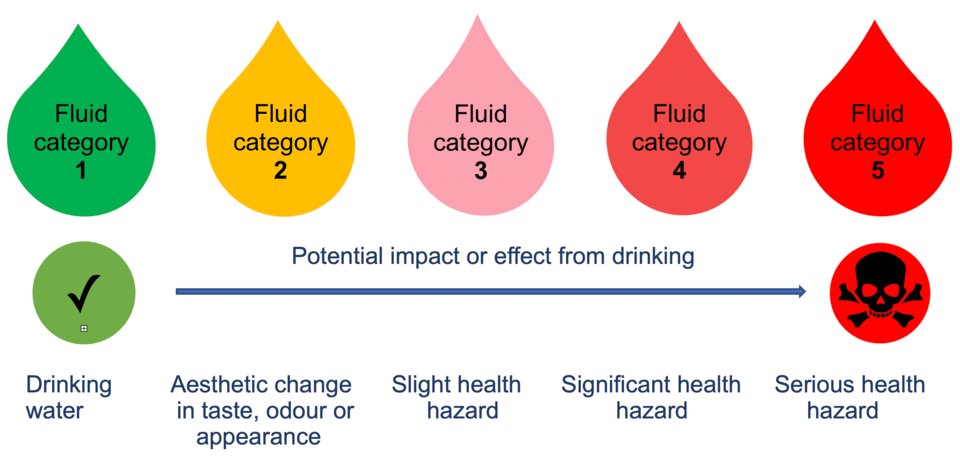

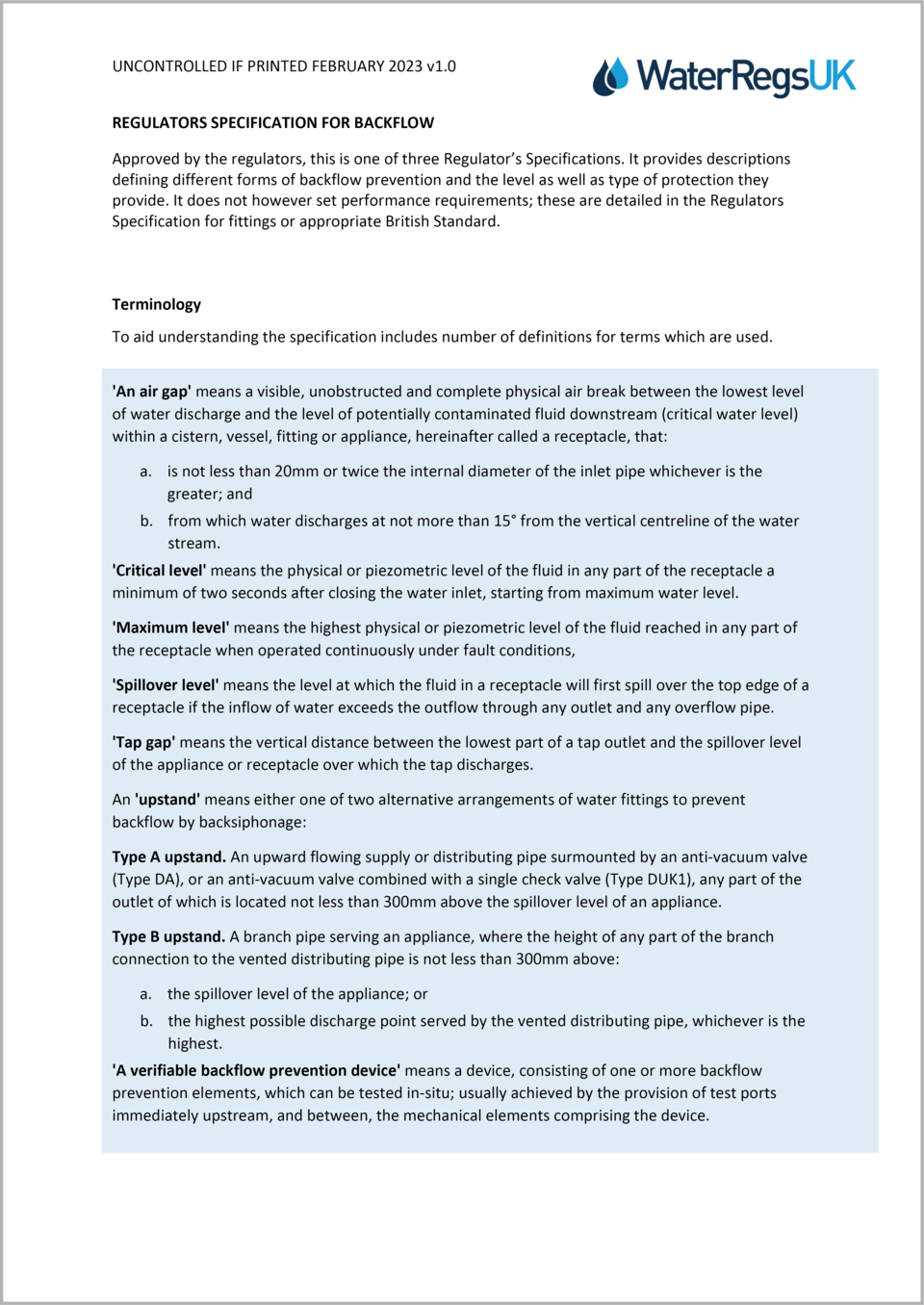

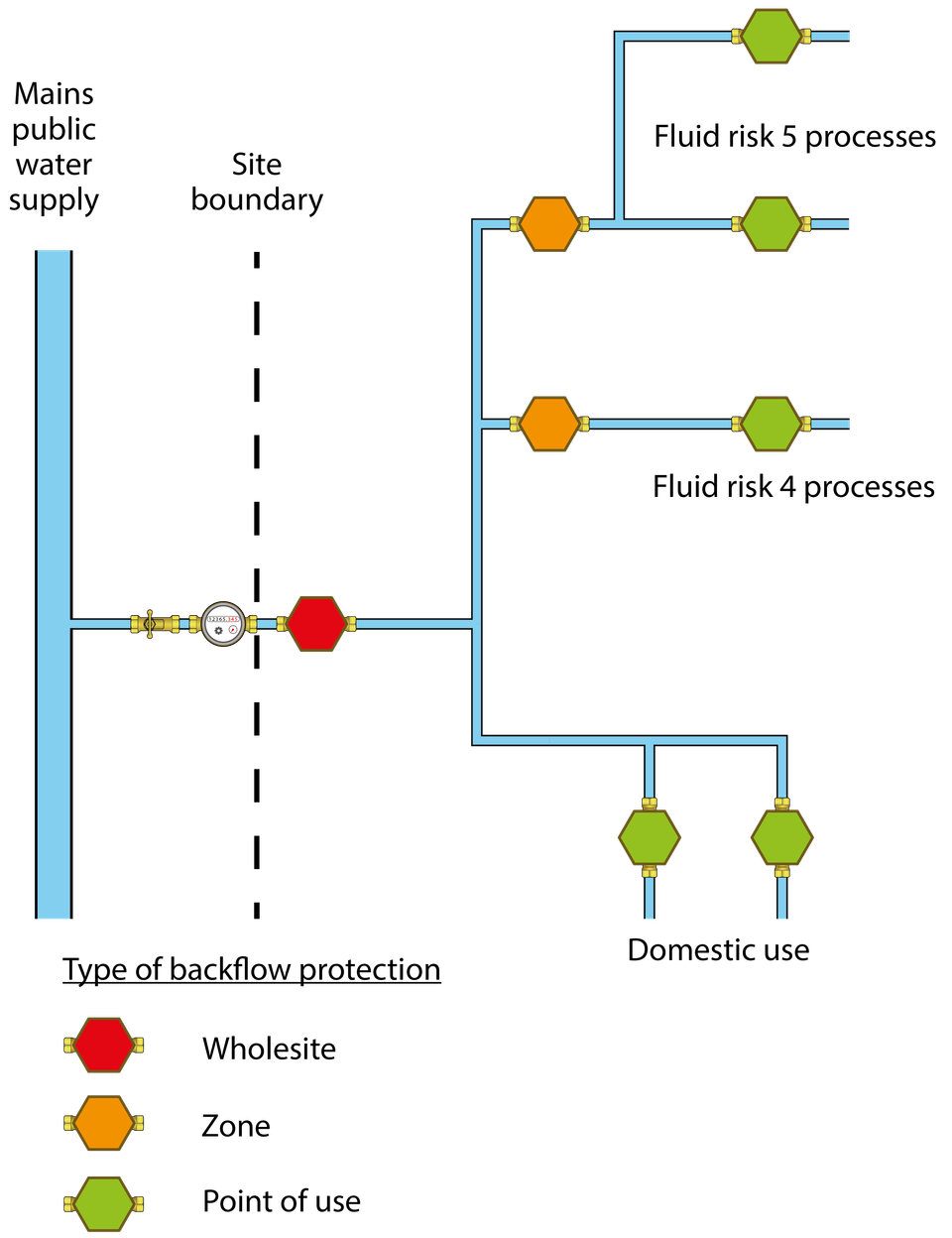

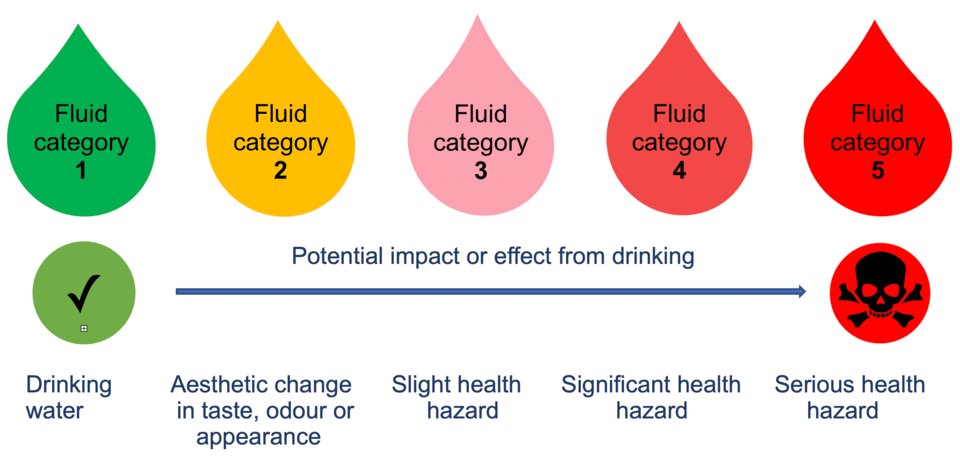

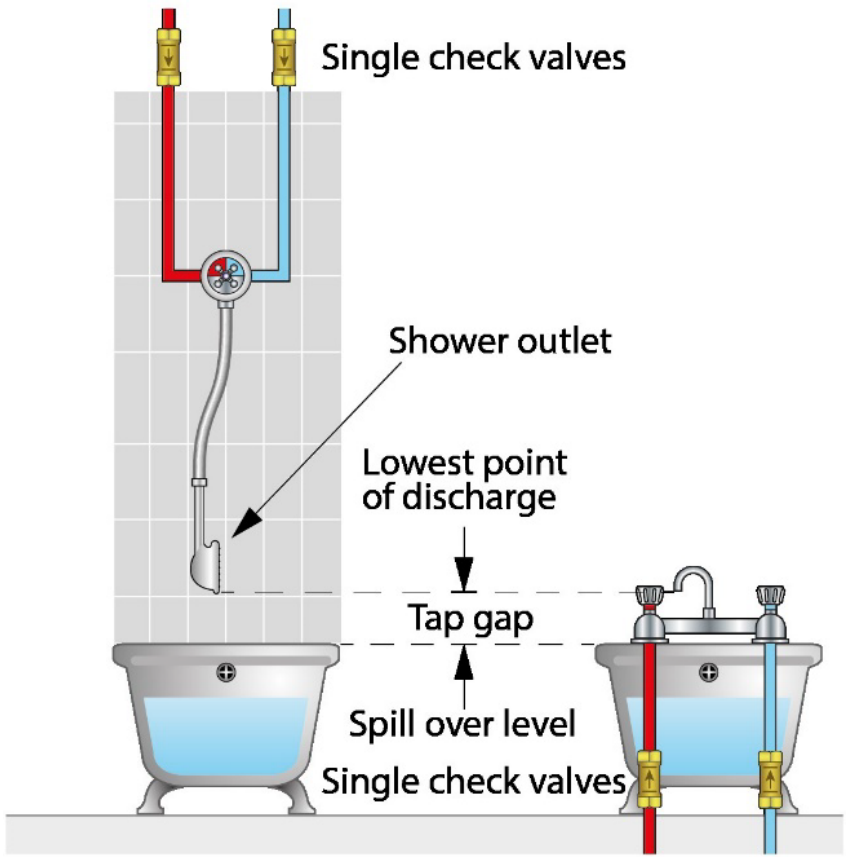

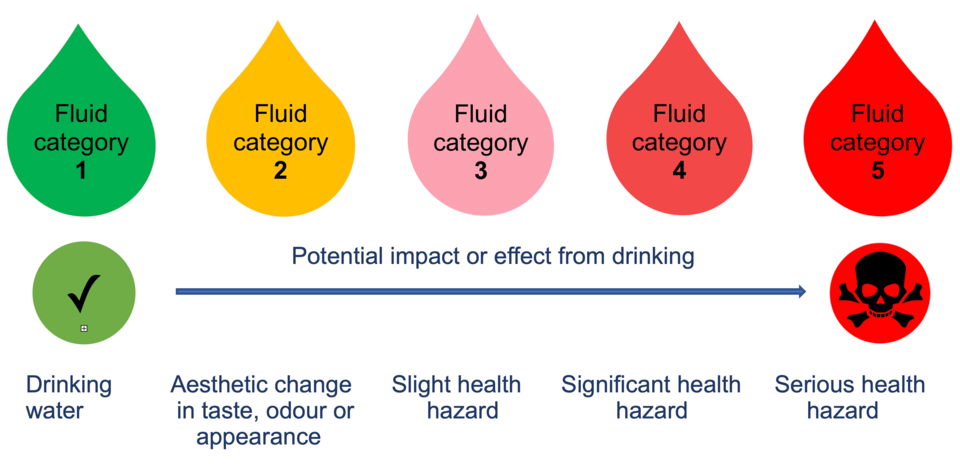

Schedule 1 of the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland, classify the health risk posed by potential contaminants using a scale called fluid categories.

There are five fluid categories in total the lowest being 1 no risk the highest 5 a serious health hazard.

Fluid Category | Description | Example |

1

|

Wholesome (drinking) water supplied by the undertaker

|

water direct from a water undertaker’s main

|

2

|

Wholesome (drinking) water which has been changed either heated or altered in taste, odour or appearance

|

Hot water

|

3

|

Fluids posing a slight health hazard

|

low toxicity chemicals such as common disinfectants

|

4

|

Fluids posing a significant health hazard.

|

Toxic substances such as pesticides and environmental organisms

|

5

|

Fluids posing a serious health hazard

|

Pathogenic organisms, radioactive or very toxic substances such as faecal matter

|

As part of their statutory duty to enforce the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland, the local water undertaker will identify the level of backflow protection needed. This categorisation will be based on a number of factors including the highest downstream fluid category risk the fitting is or is likely to be subject.

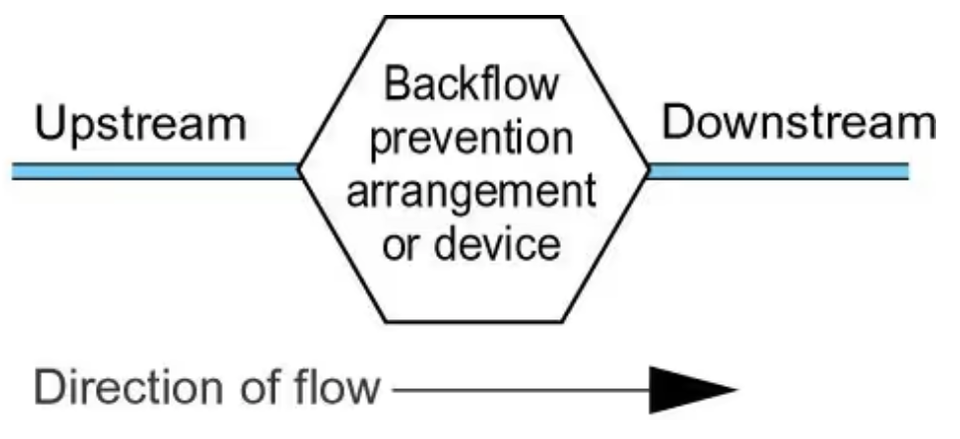

It is in effect a barrier intended to prevent contaminated fluid flowing backwards.

Schedule 2 paragraph 15 of the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland require every plumbing system to incorporate protection against backflow. This is often referred to as point of use backflow protection. It can be provided by an air or tap gap arrangement or a mechanical backflow prevention device.

Backflow prevention arrangements and devices permitted under the regulations/byelaws need to be approved by the regulator or alternatively authorised as a relaxation. Relaxations allow a water undertaker the discretion to accept an arrangement as preventing backflow.

The regulator rates a backflow protection arrangement or device for suitability against contamination risk (fluid categories) and types of backflow risk - back siphonage or back pressure. They should always be accessible for inspection, maintenance and replacement.

Backflow prevention devices, are required to be corrosion resistant. For example, for metallic backflow prevention devices manufactured of gunmetal or other dezincification resistant materials. Dezincification water fittings are typically marked with a CR symbol.

Wherever practicable plumbing systems should be protected against backflow without the necessity to rely on mechanical backflow protection devices.

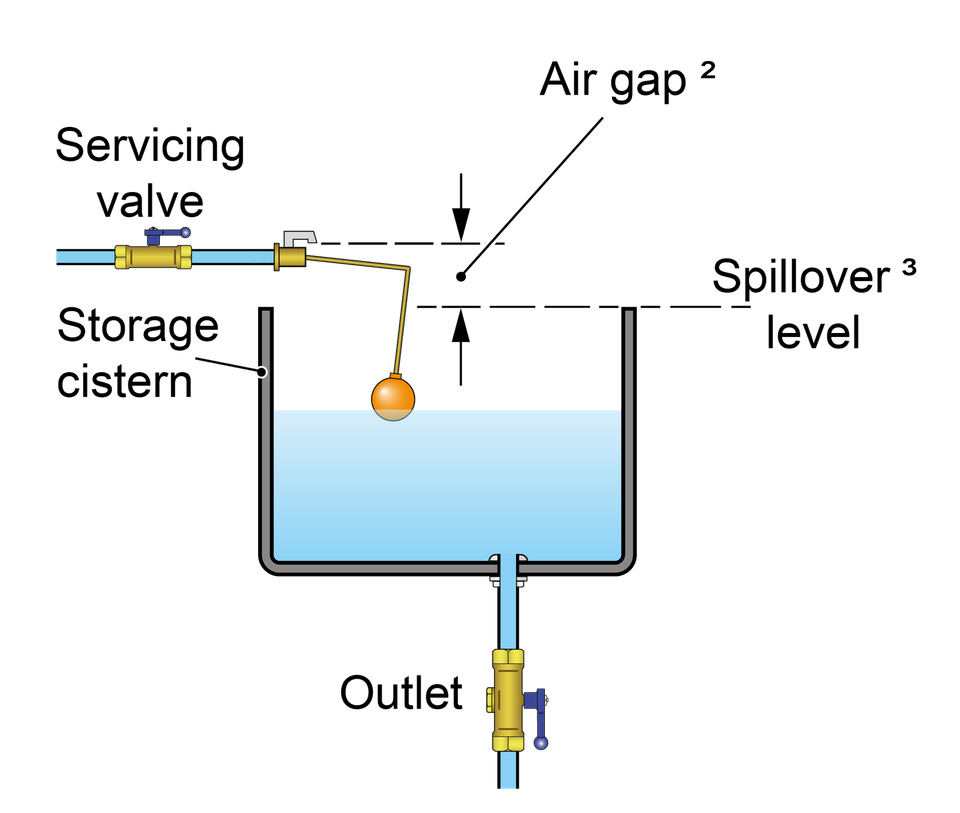

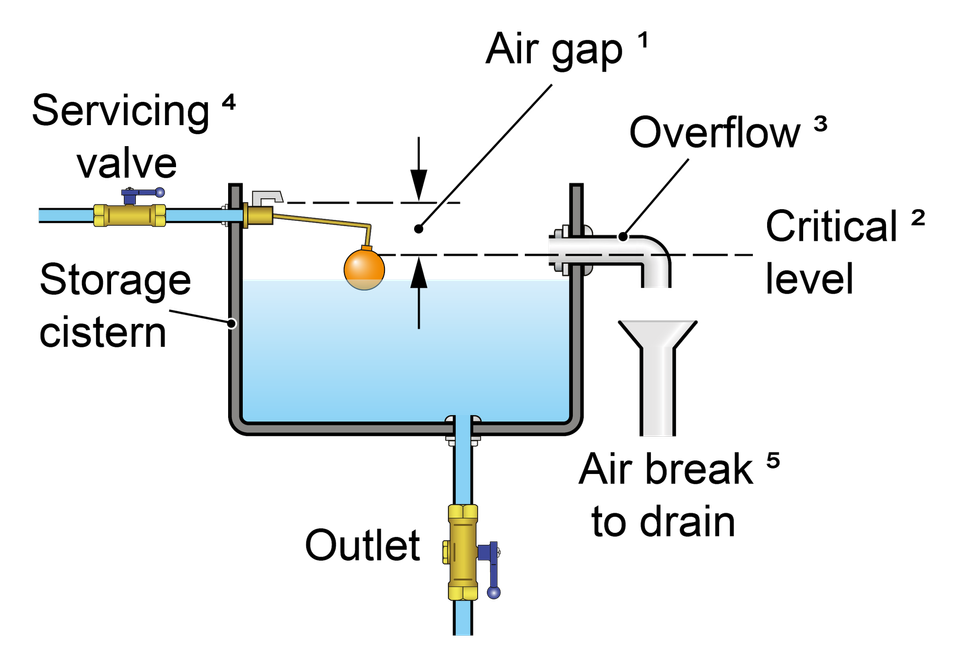

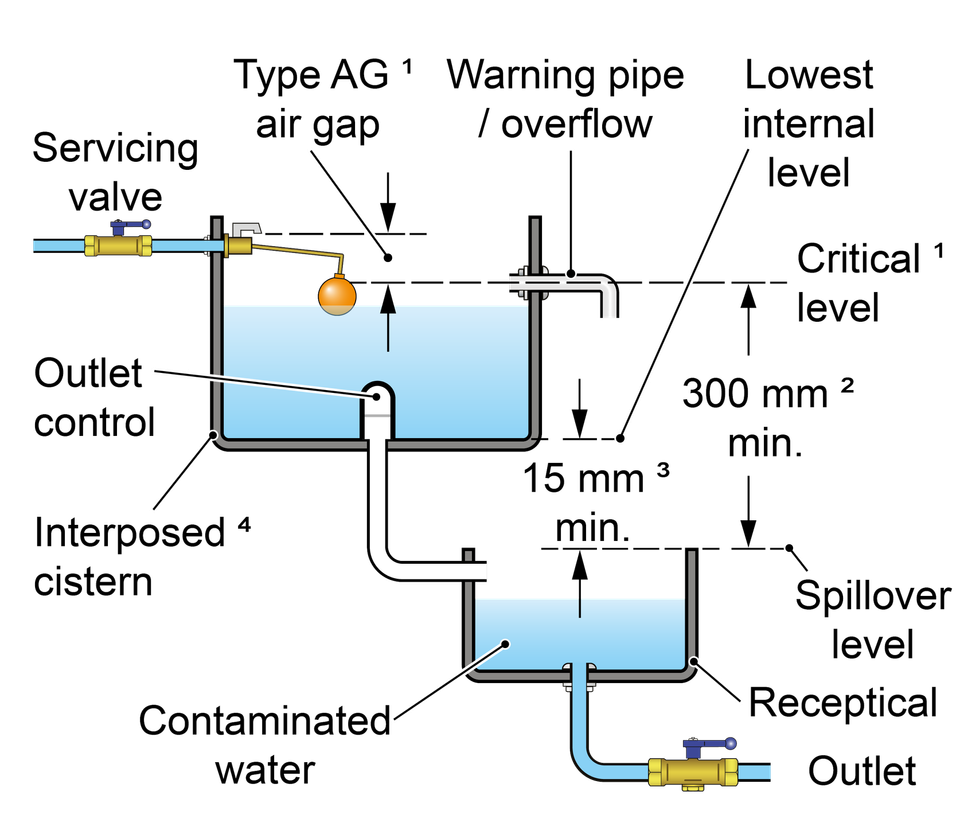

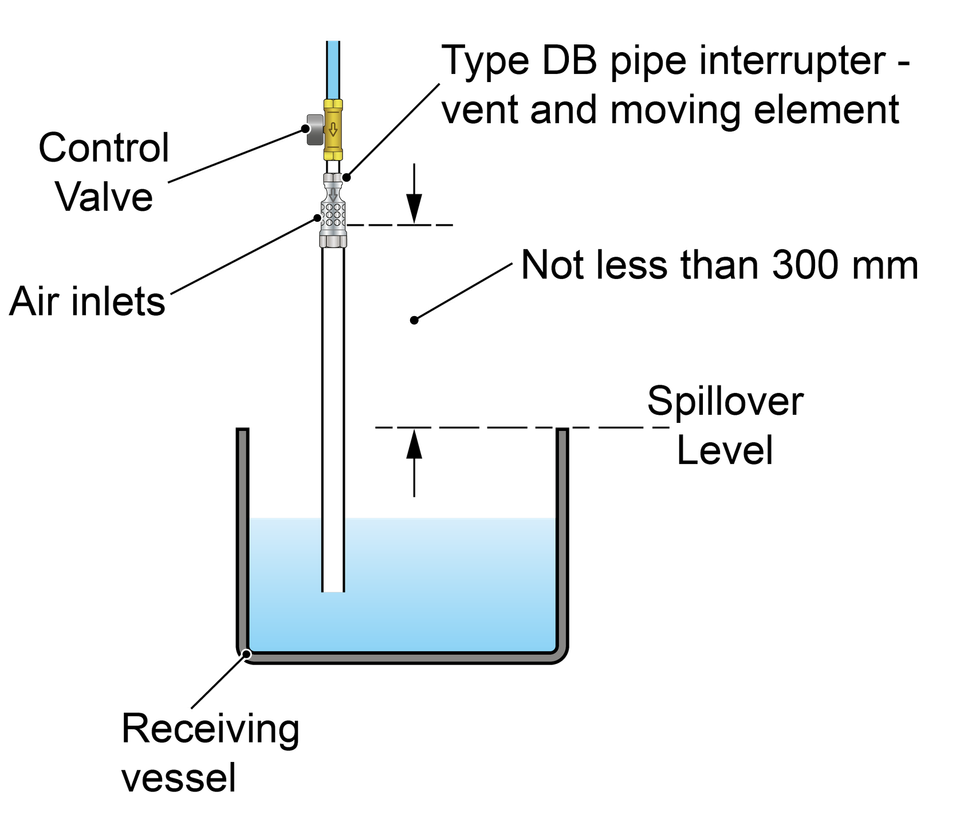

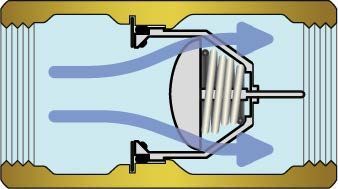

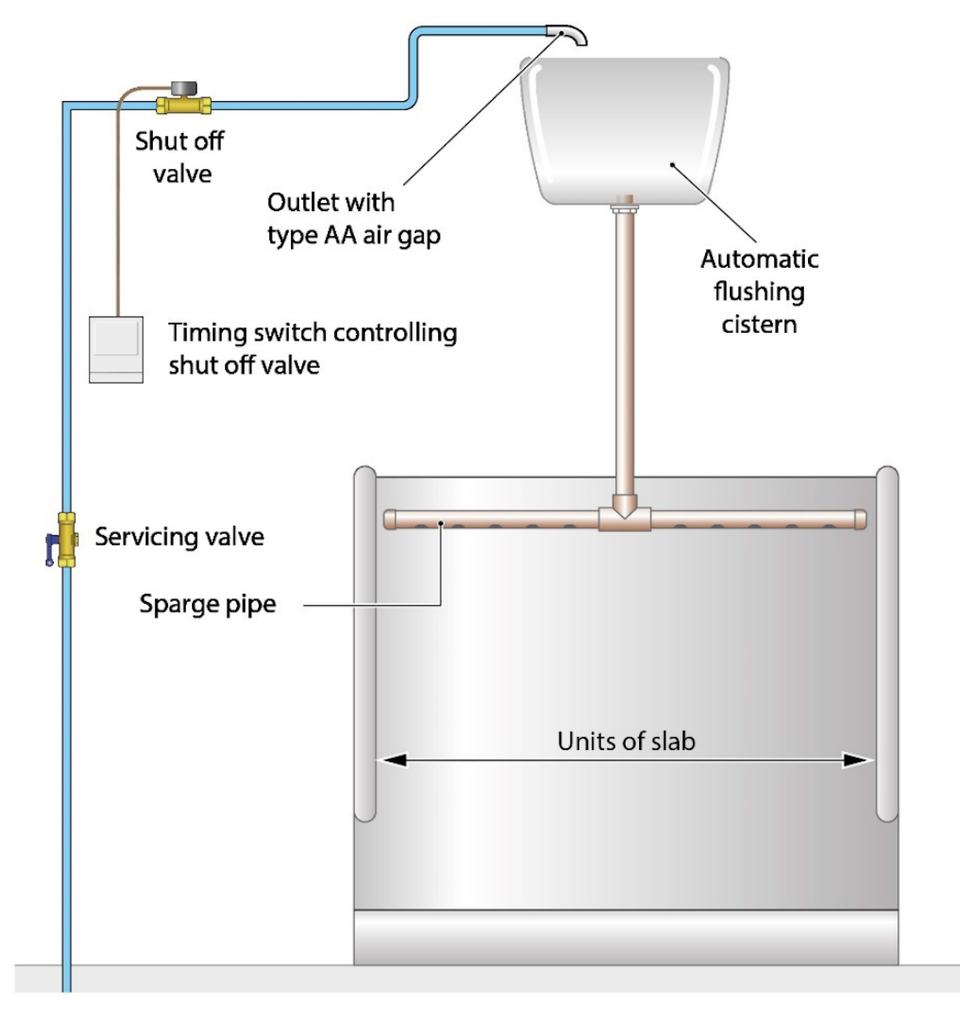

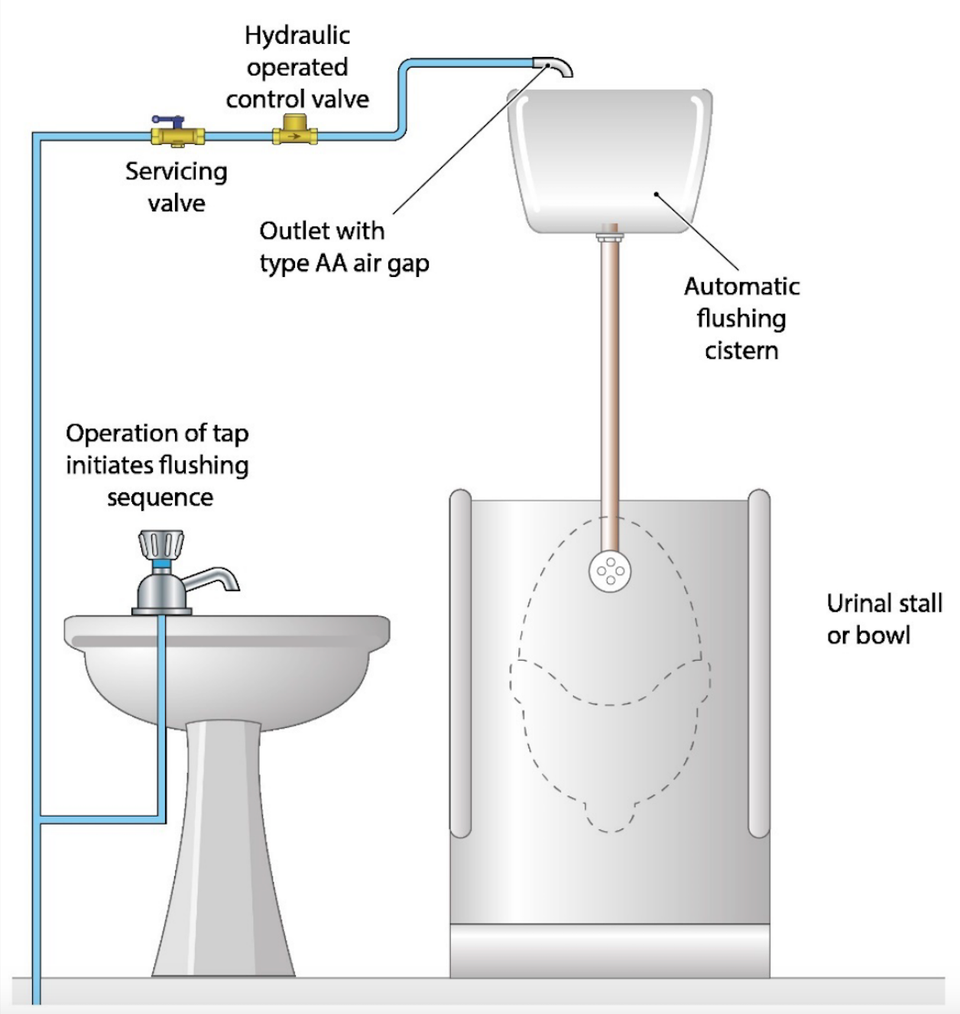

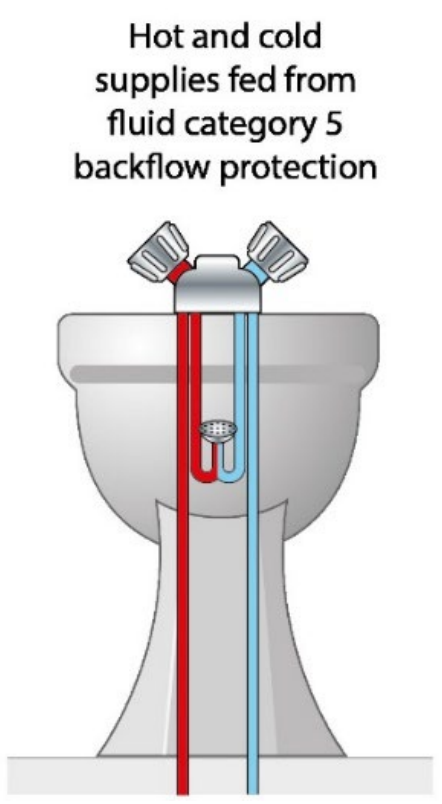

A Type AA air gap is a non-mechanical backflow prevention arrangement comprising of an inlet which discharges water into a cistern, vessel, fitting or appliance (receiving vessel) and an outlet. Depending on the outcome of an assessment by the local water undertaker it can feed a single or multiple installations.

A Type AA air gap is rated by the Regulators as suitable backflow protection against both back siphonage and back pressure at the highest level of contamination risk, fluid category 5.

A summary of some of the key requirements for a Type AA air gap is given below:

The supply pipe and inlet control must be external to the receiving vessel and fixed so the air gap is maintained and unrestricted.

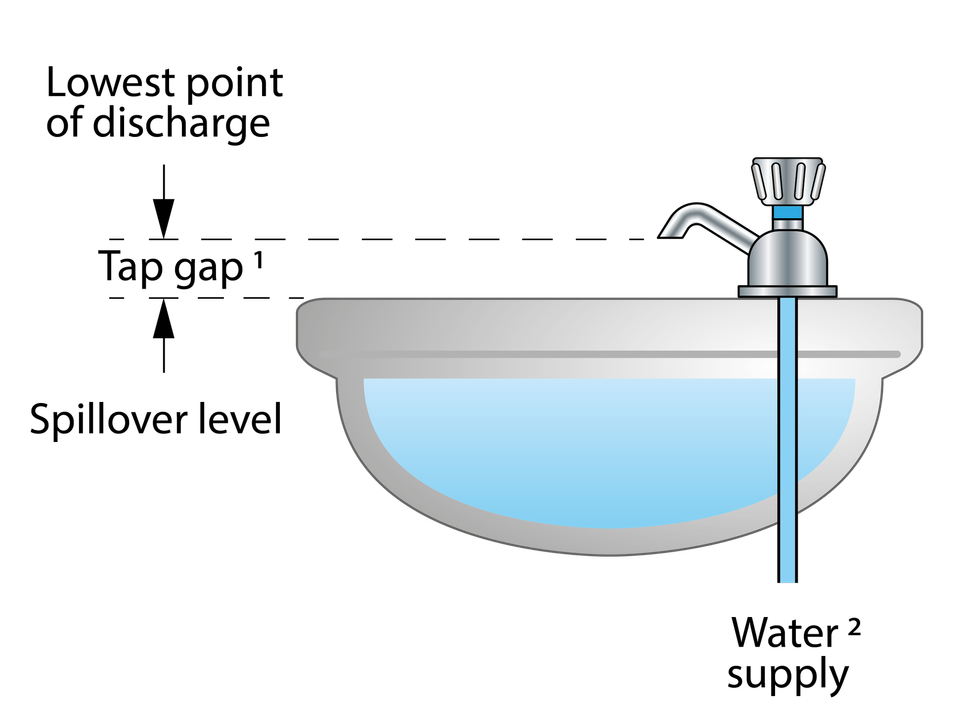

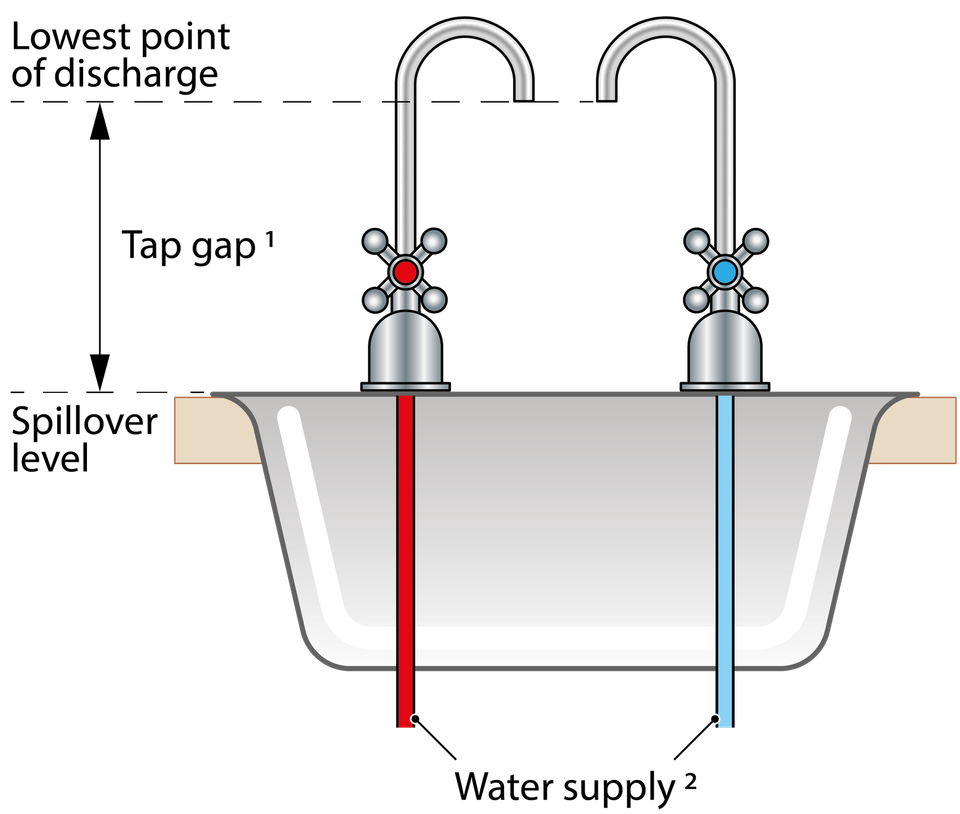

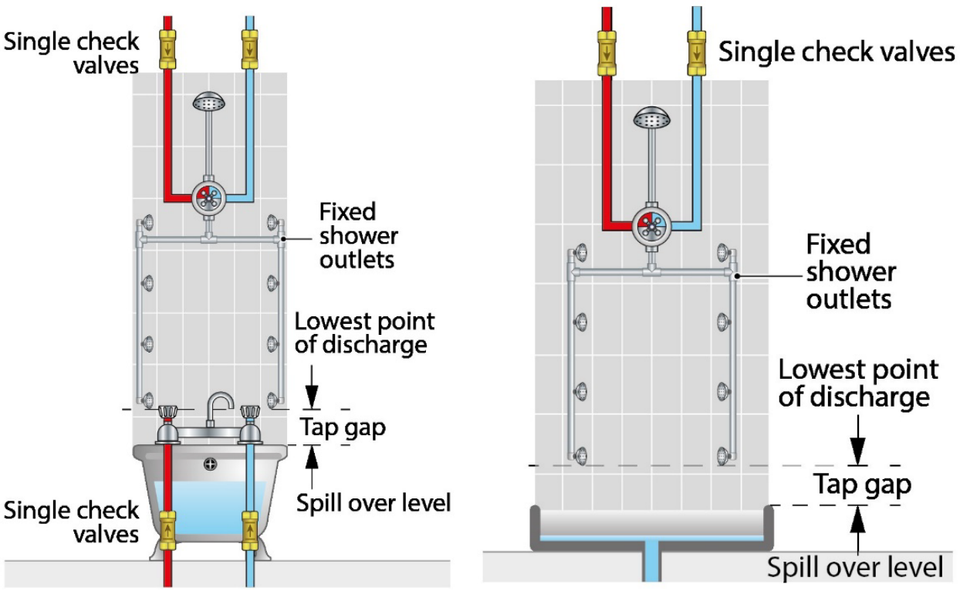

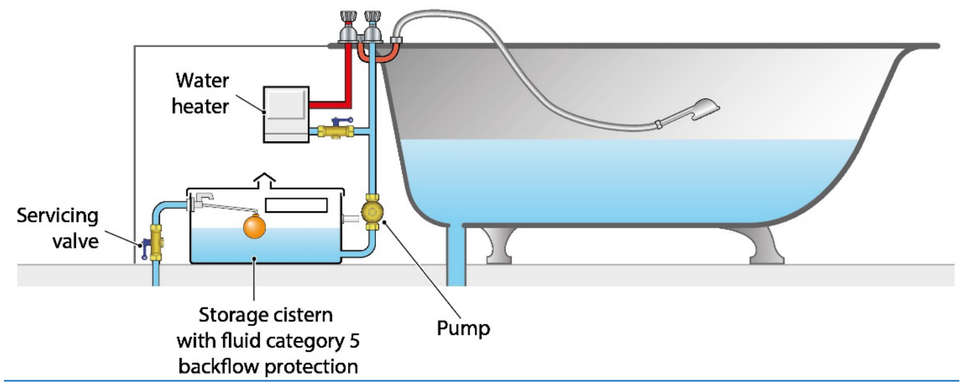

The air gap is an unobstructed and complete physical break between the lowest point of discharge and the spillover level of the contents of the receiving vessel. Measured vertically it must be no less than 20 mm or twice the internal diameter of the supply whichever is the greater.

The spillover level is the level at which the contents of receiving vessel spill over the top edge when the inflow of water exceeds the outflow through the outlet i.e. demand.

The spillover is unrestricted.

If the supply pipe feeding the inlet or the inlet itself comes into contact with the contents of the receiving vessel, for example due to splashing or foaming, then the air gap is considered to be compromised and must be increased to the point no contact occurs.

Type AA air gaps should be inspected, and as necessary, maintained every 6 months (BS EN 806: 5)

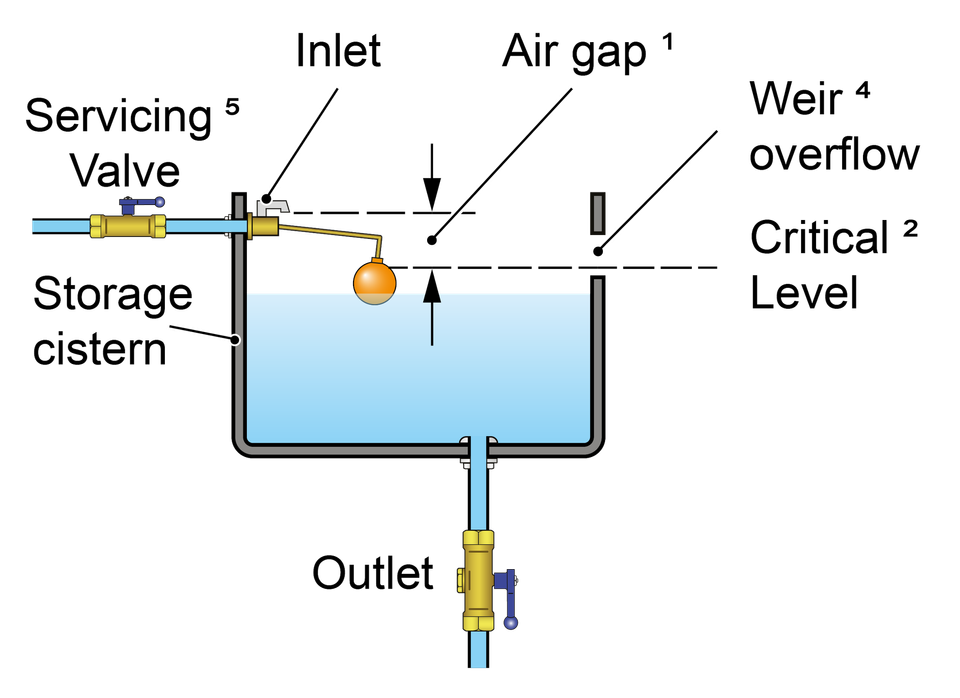

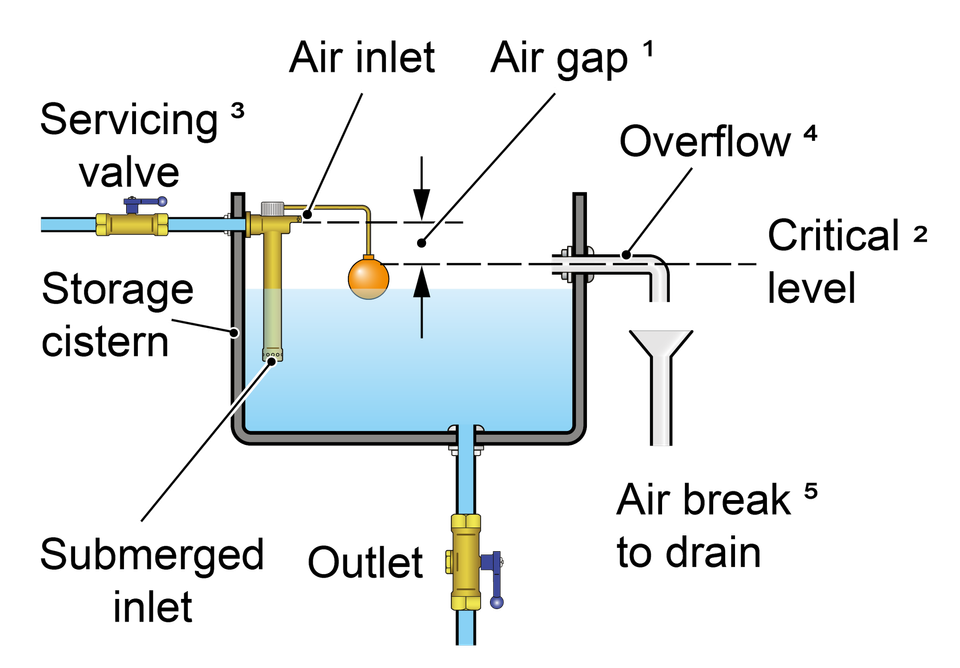

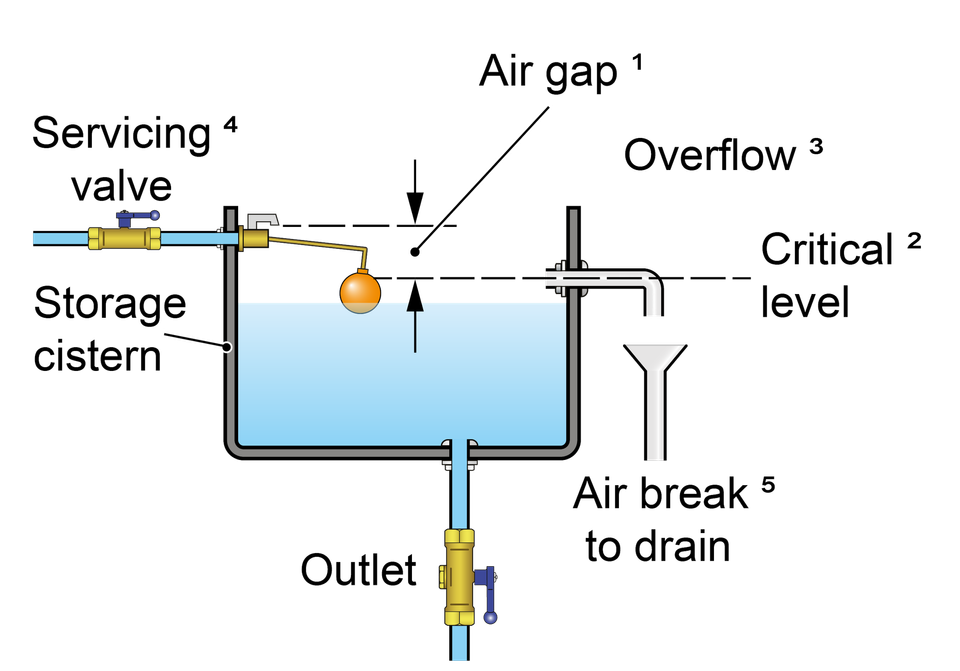

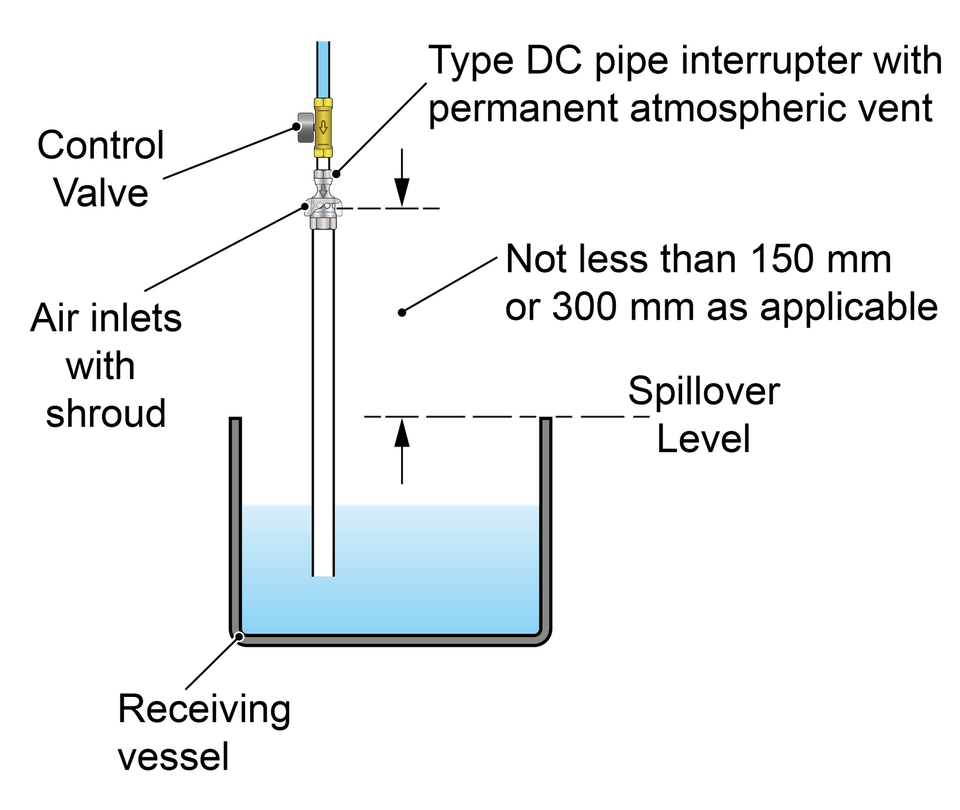

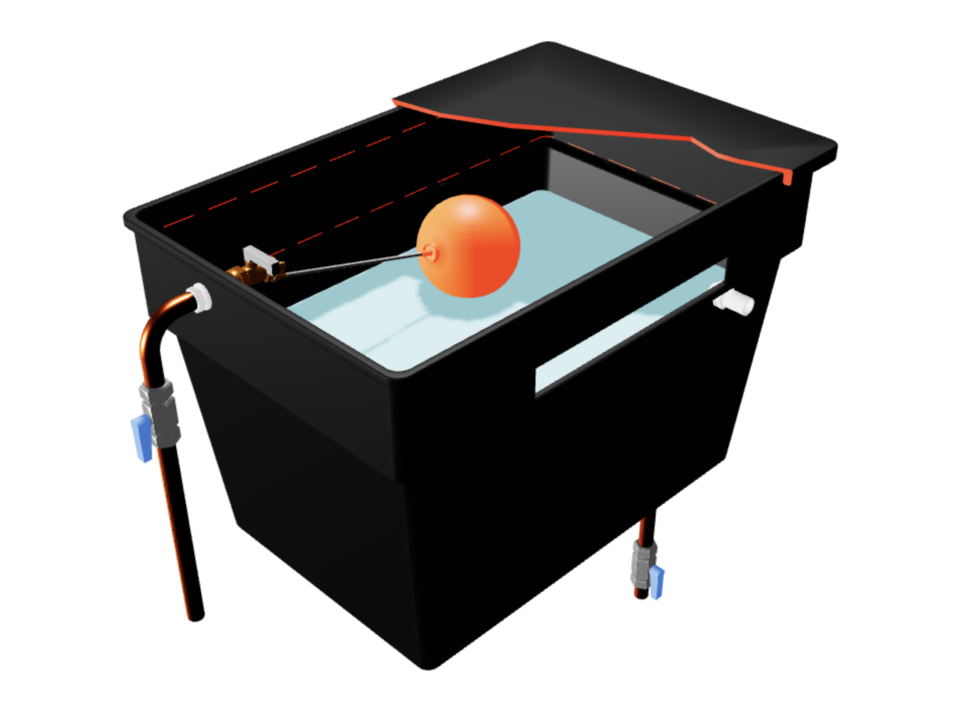

A Type AB air gap is a non-mechanical backflow prevention arrangement comprising of an inlet which discharges water into a cistern, vessel, fitting or appliance (receiving vessel) fitted with an outlet and a rectangular weir or ‘slot’ overflow. Depending on the outcome of an assessment by the local water undertaker it can feed a single or multiple installations.

A Type AB air gap is rated by the Regulators as suitable backflow protection against both back siphonage and back pressure at the highest level of contamination risk, fluid category 5.

A summary of some of the key requirements applicable to a Type AB air gap is given below:

The air gap is an unobstructed and complete physical break between the lowest point of discharge and the critical water level of the weir overflow. Measured vertically it must be no less than 20 mm or twice the internal diameter of the supply whichever is the greater.

The critical level (sometimes referred to as h) is the fluid level in the receiving vessel under fault conditions i.e. when the outlet is closed but the inlet continues to discharge. It is measured at least 2 seconds after closing the water inlet

Whether sited internally or externally (as shown in the diagram opposite) the weir overflow must be rectangular (non-circular) and capable of accommodating discharge under fault conditions. Where a screened mesh is installed consideration should be given to the impact this may have on discharge flow. The air gap can be confirmed by test or calculation using the Type AB air gap calculator.

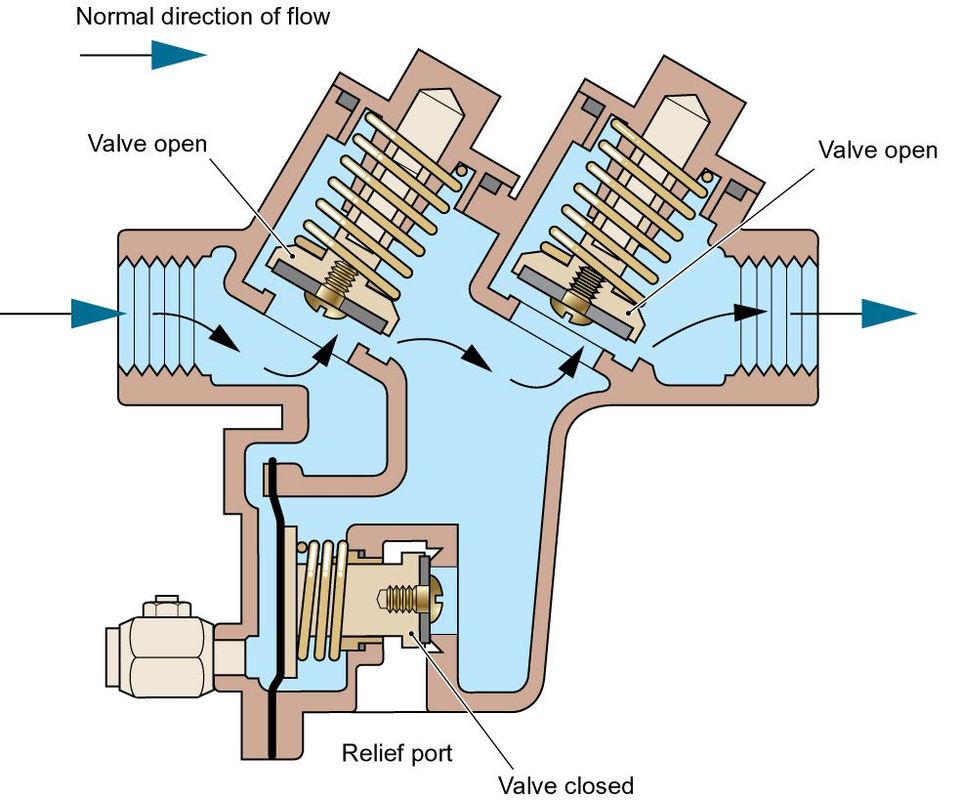

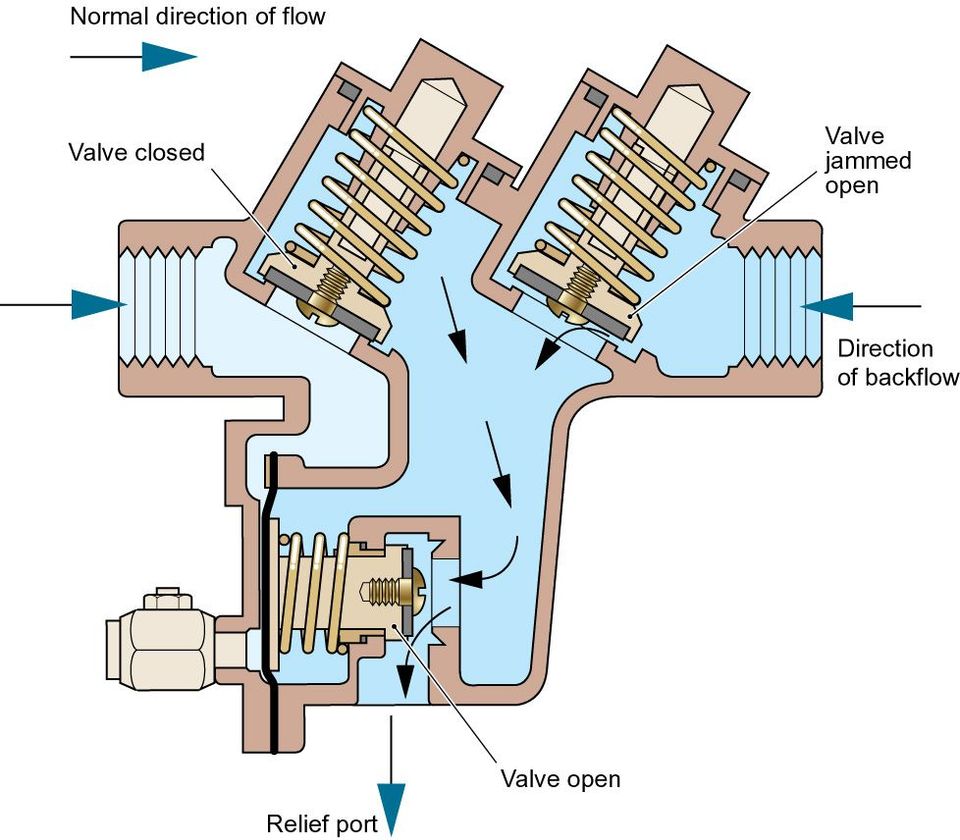

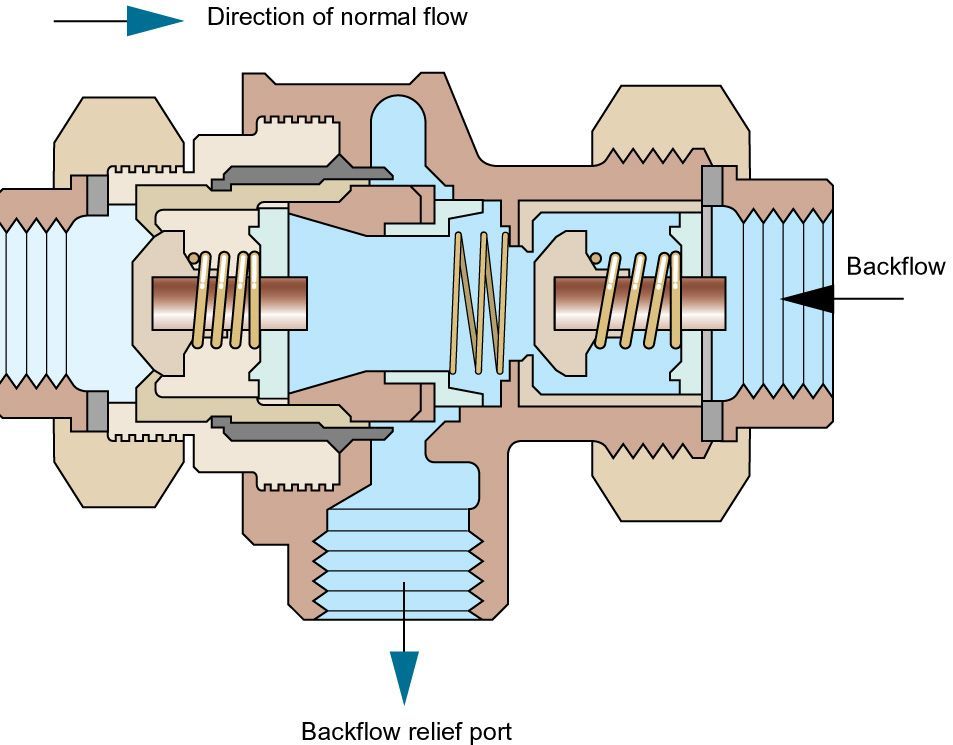

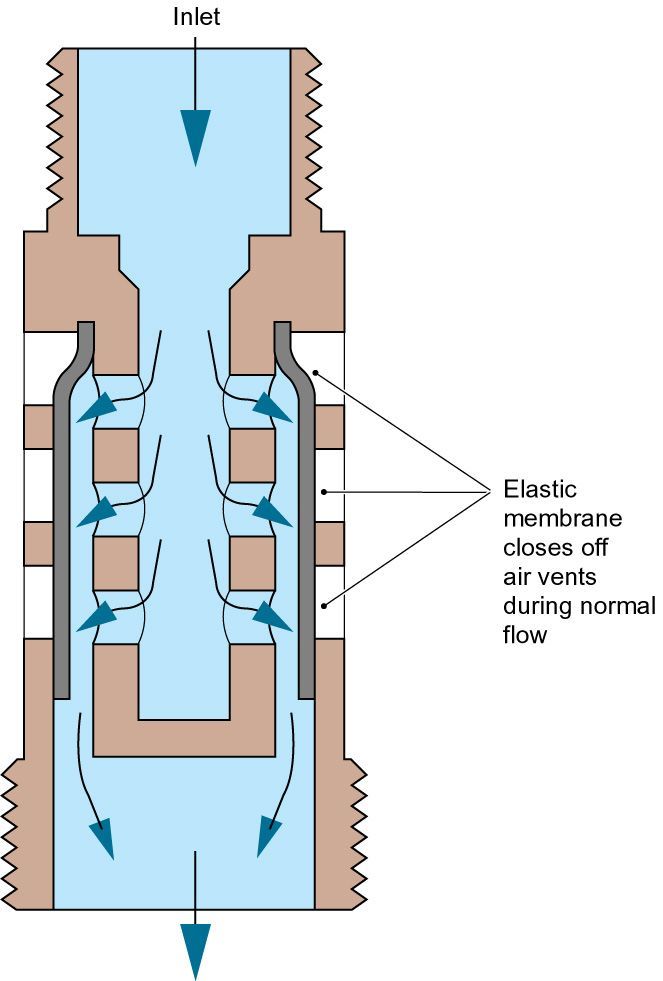

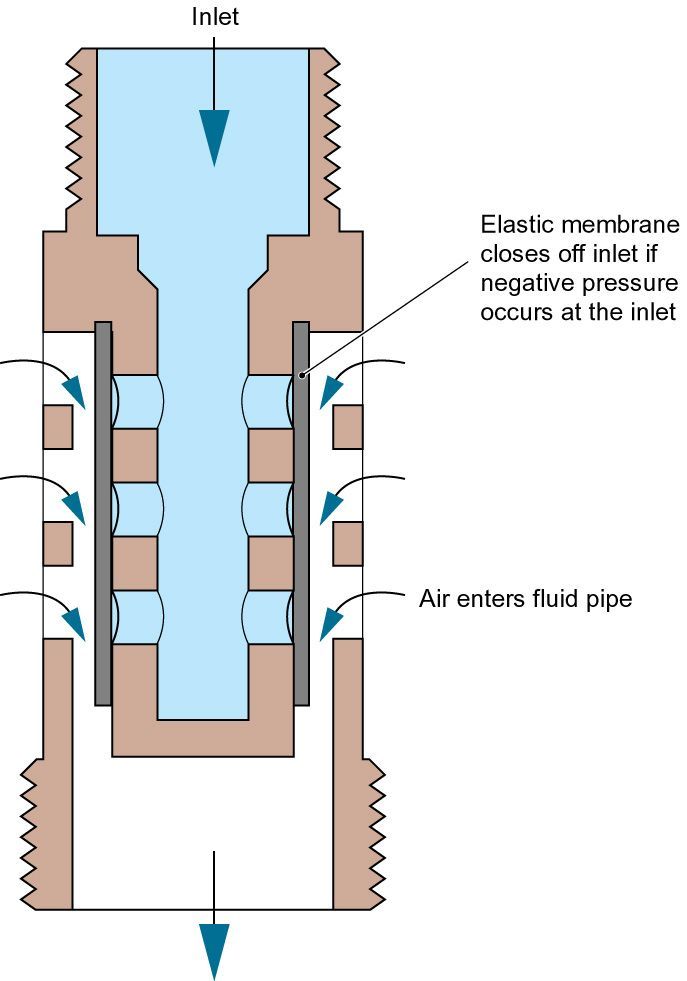

Neither the fluid pathway to the overflow nor the discharge from it should be restricted. For example, there should be a sufficient gap between the overflow and any surface to accommodate full discharge unimpeded during fault conditions.